Quick Start Guide

5

August 2012

Installation recommendations

Avoid installing near liquid entering the tank at the fill point

Avoid heavy splashing on the forks.

Increasing the time delay reduces accidental switching

Avoid installing near heat sources

Ensure the fork does not come into contact with the tank/pipe wall, or fittings

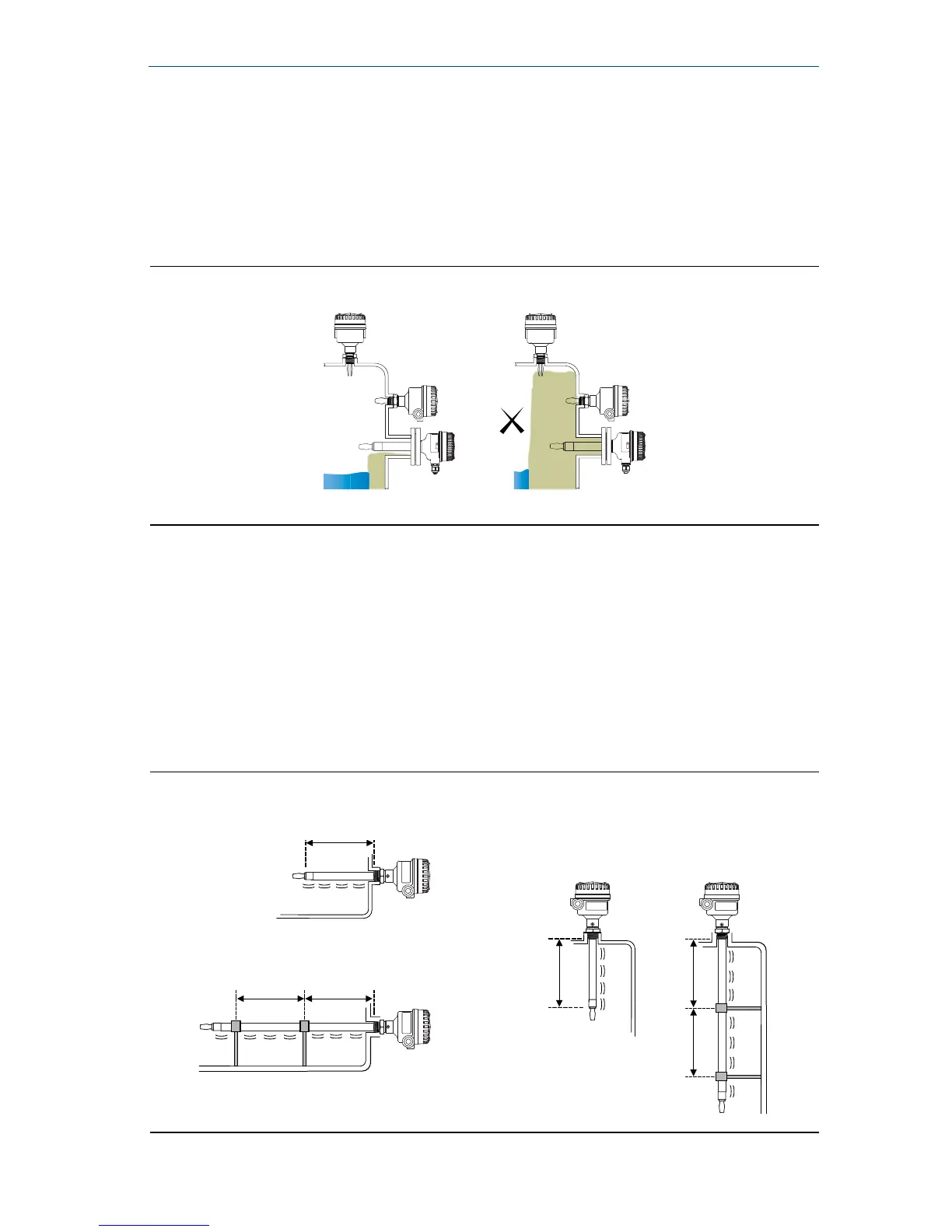

Allow a sufficient distance between product build-up on the tank wall and fork

Figure 4. Avoid product build-up around the forks

Step 1: Physical installation

1. Install the 2120 according to standard installation practices, making sure to

correctly align the fork using the alignment notch or groove (Figure 6).

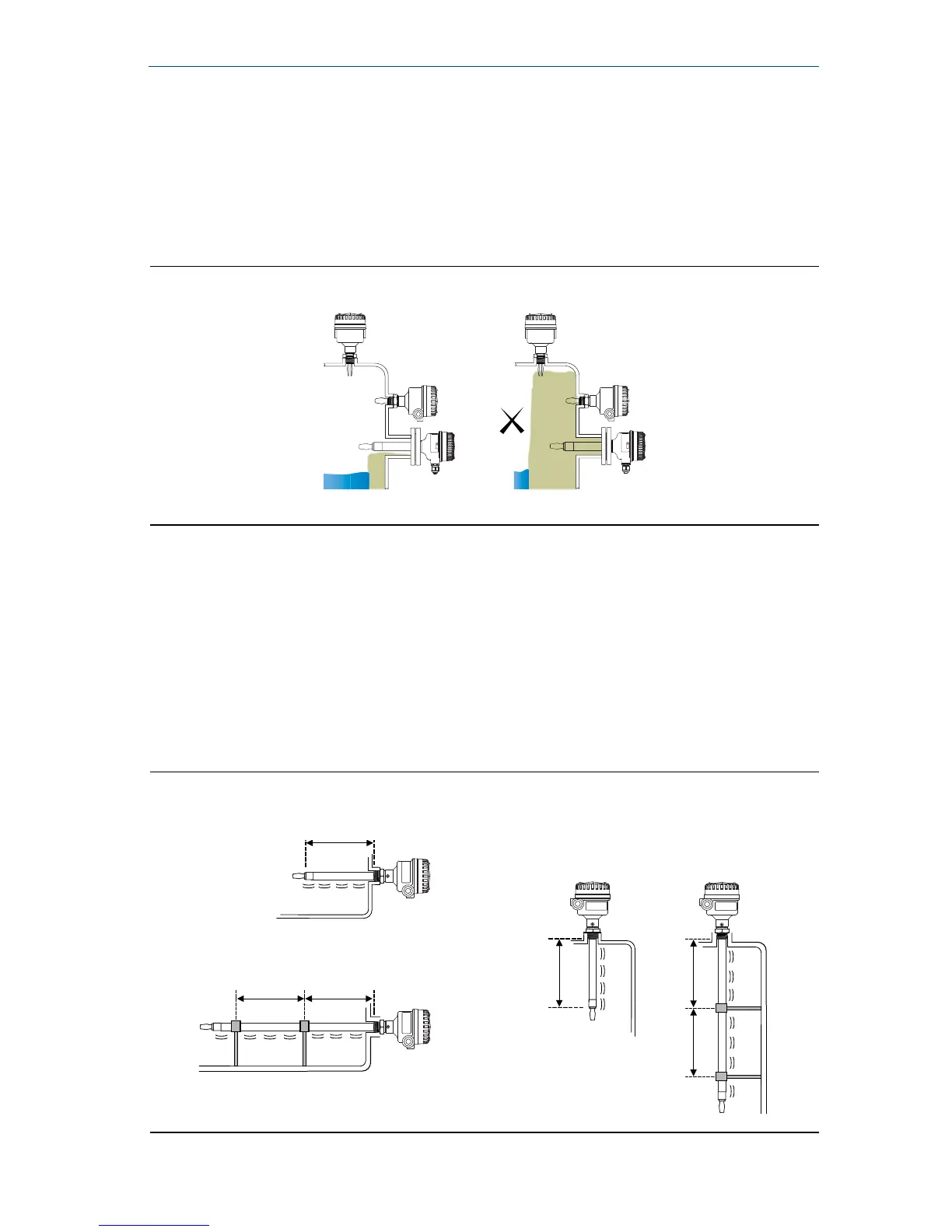

2. Use supports for extended fork lengths greater than 3.2 ft. (1 m) (Figure 5).

For the GL approval requirements, see reference manual 00809-0100-4030.

3. Close the housing cover and tighten to safety specification. Always ensure a proper

seal so that metal touches metal or plastic touches plastic, but do not over tighten.

4. Insulate the 2120 with Rockwool. See Figure 7 for clearances.

Figure 5. Supports needed for an extended fork (standard)

OK

Loading...

Loading...