4 x Set-up and installation

FA ROTEX A1 BGe - 02/2014

15

Flue gas system resistance

To ensure safe burner start-up and stable setting values, a

minimum resistance is required in the flue gas line, particularly

with liquid gas units. If this is not achieved you need to fit a si-

lencer (E8 MSD, 15 45 78 or E11 MSD, 15 45 79).

– With the hot water storage tank connected and activated stor-

age tank temperature sensor, the ROTEX A1 initially switches

into storage charging mode after the burner starts. In this

mode, the burner blower runs with max. speed.

– If there is no hot water storage tank connected, the resistance

of the flue gas system with completely open heat distribution

valves in "Manual Operation" (see chapter 10.5 or documen-

tation "ROTEX RoCon BF Controller") or in the setting "Full

Load" for the emission measurement (see chapter 15.2)

needs to be determined.

Ɣ Measure the resistance with the differential measurement unit

on the flue gas measurement point between the flue gas and

intake air measurement openings (differential pressure for the

A1 BG 25(F)-e at 0.5 mbar, for the A1 BG 40(F)-e at least

1 mbar).

Tab. 4-3 shows the maximum permissible height of the flue gas

line for the case that the ROTEX A1 is operated in the nominal

output range.

1) Cross section of the shaft: 135 mm x 135 mm

2) Cross section of the shaft: 160 mm x 160 mm

Tab. 4-3 Maximum permitted height of the flue gas pipe in m (when

operating in the nominal output range)

Any restriction on the output range may require a recalculation of

the maximum permitted height for the flue gas pipe. The charac-

teristics for the flue gas calculation can be obtained from fig. 4-6

and chapter 15 "For the chimney sweep".

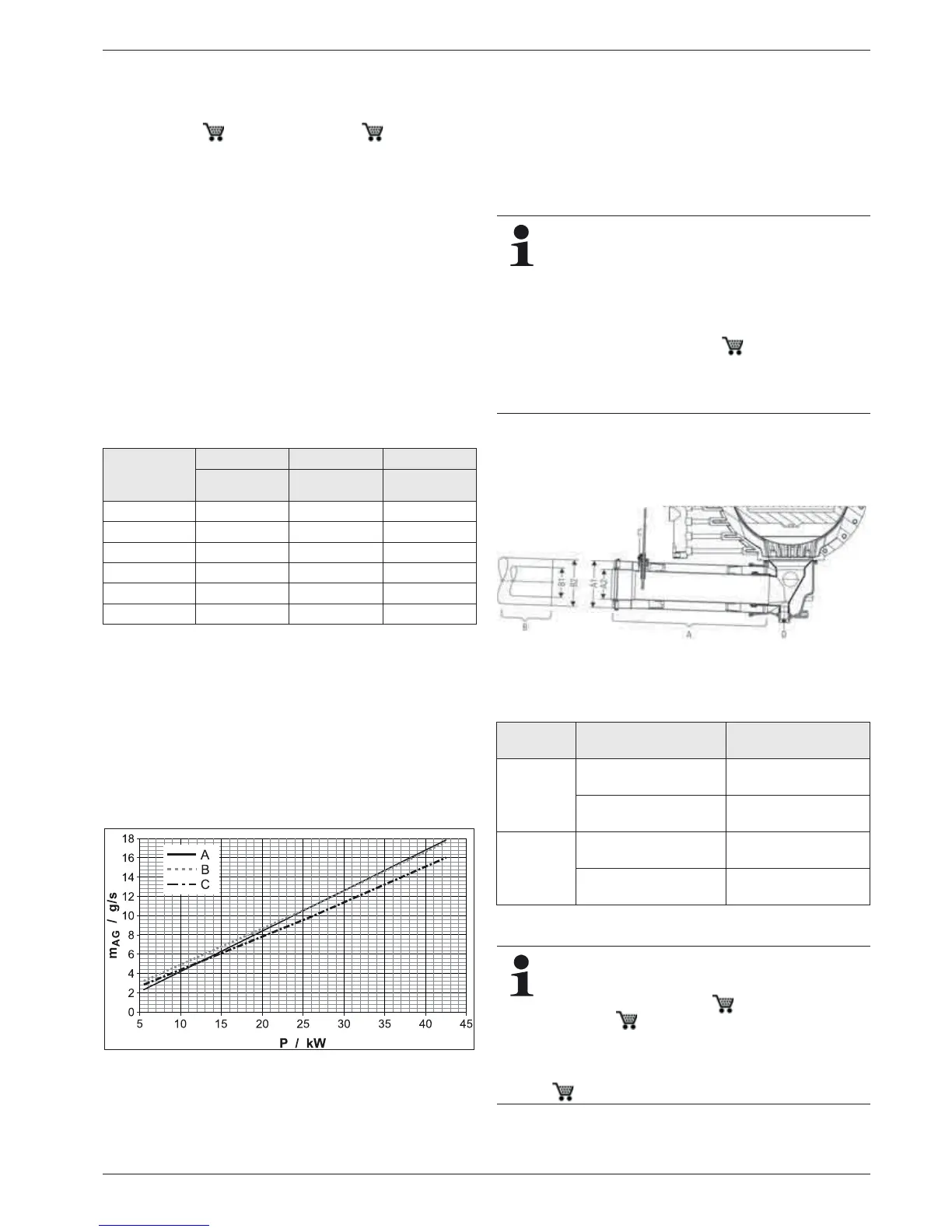

The flue gas mass flow of the systems depends on the burner

output set.

4.5.2 Connecting the flue gas line to the ROTEX A1

Requirements

– The flue system fulfils the requirements described in

section 4.5.1.

– The flue system fulfils any other required national or regional

safety requirements.

– The ROTEX A1 is installed correctly.

Connection

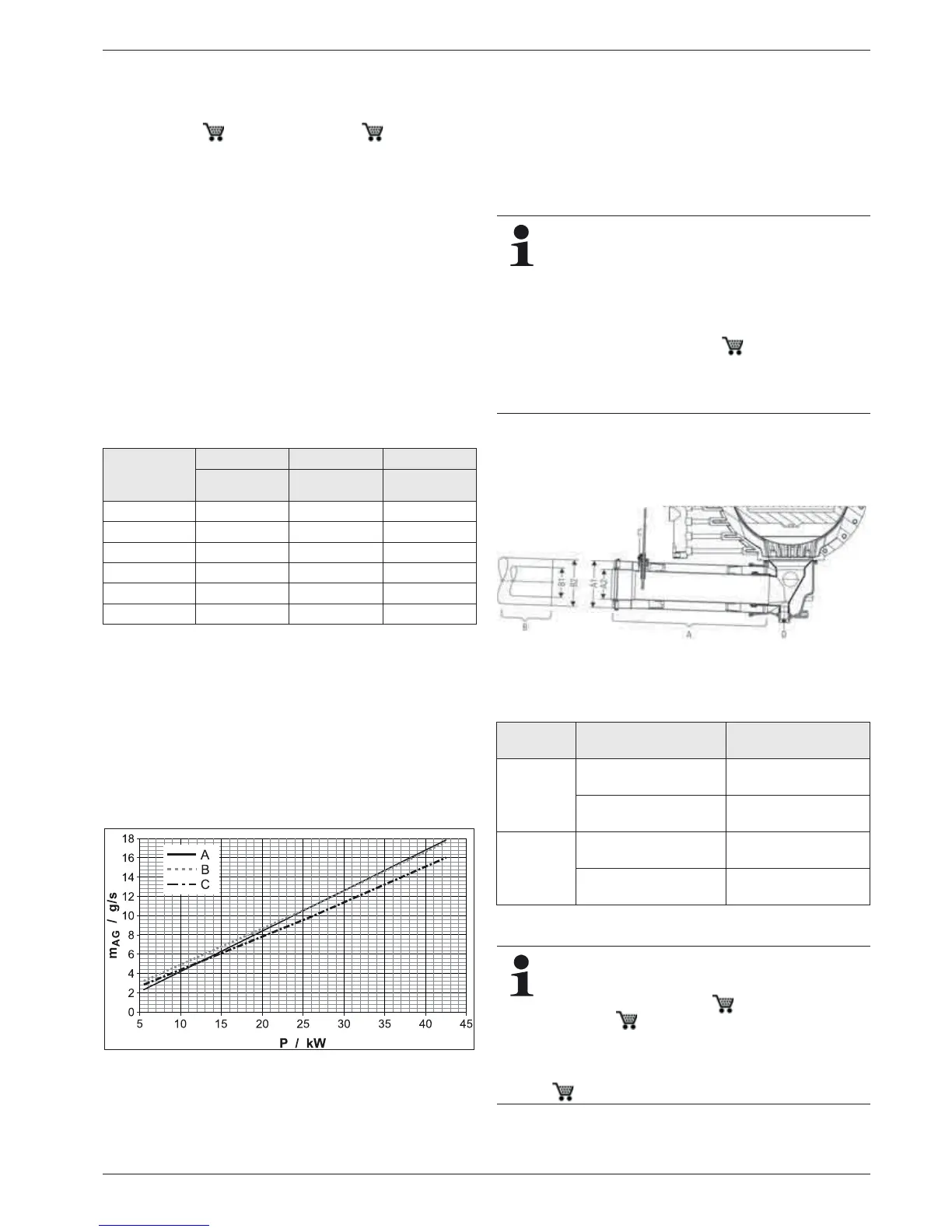

Ɣ Connect ROTEX A1 to the flue gas system within the place of

installation (for pipe dimensions, see fig. 4-2 or fig. 4-7).

Ɣ Place the nameplate of the flue gas pipe in the installation

room.

Tab. 4-4 Connection dimensions for LAS connection to the ROTEX A1

Set-up

version

(ref. fig. 4-4)

A1 BG 25(F)-e A1 BG 40(F)-e A1 BG 40(F)-e

DN 80 DN 80 DN 110

123

1)

8

1)

22

2)

222

1)

17

1)

40

2)

322

1)

17

1)

25

2)

4211417

52210 -

62210 -

A Natural gas E, H

B Natural gas L, LL

C Fluid gas (propane, butane)

m

AG

Flue gas mass flow in g/s

P Burner load in kW

Fig. 4-6 Flue gas mass flow in relation to the burner output

Basically, any flue gas line that complies with the

minimum requirements according to the EN 14471 and

that has the CE-labelling can be connected

(see section 4.5.1).

Each flue gas line must be installed with a suitable test

adapter for checking and setting the combustion

values. The ROTEX LAS construction sets each in-

clude a test adapter (D8 PA, 15 50 79.00 93).

We recommend the use of the associated ROTEX flue

gas set (see fig. 4-8). They satisfy all requirements and

are also fitted with special acid-proof seals.

A Boiler connection

B Flue gas connection

C Flue gas temperature sensor

D Connection for condensate

drain

Fig. 4-7 Connection dimensions for LAS connection to the ROTEX A1

Connection

side

Connection Connection

dimension in mm

A Boiler side A1 Flue gas DN 80

Collar

Inside diameter

= 80.4

+0.8

A2 Supply air DN 125

Collar

Inside diameter

= 127.0

–0.5

B Flue gas

side

B1 Flue gas DN 80 Outside diameter

= 80.0

+0.3

B2 Supply air DN 125 Outside diameter

= 126.0

±0.3

In some cases, the resonance in the flue system can

amplify the noise at the mouth of the flue gas pipe. The

noise level can be effectively reduced with the applica-

tion of a silencer (E8 MSD, 15 45 78 bzw.

E11 MSD, 15 45 79).

Air suction noises are generated during ambient air-

dependent operation. The noise level can be effectively

reduced with the application of a silencer (G ZLSD,

15 45 77).

Loading...

Loading...