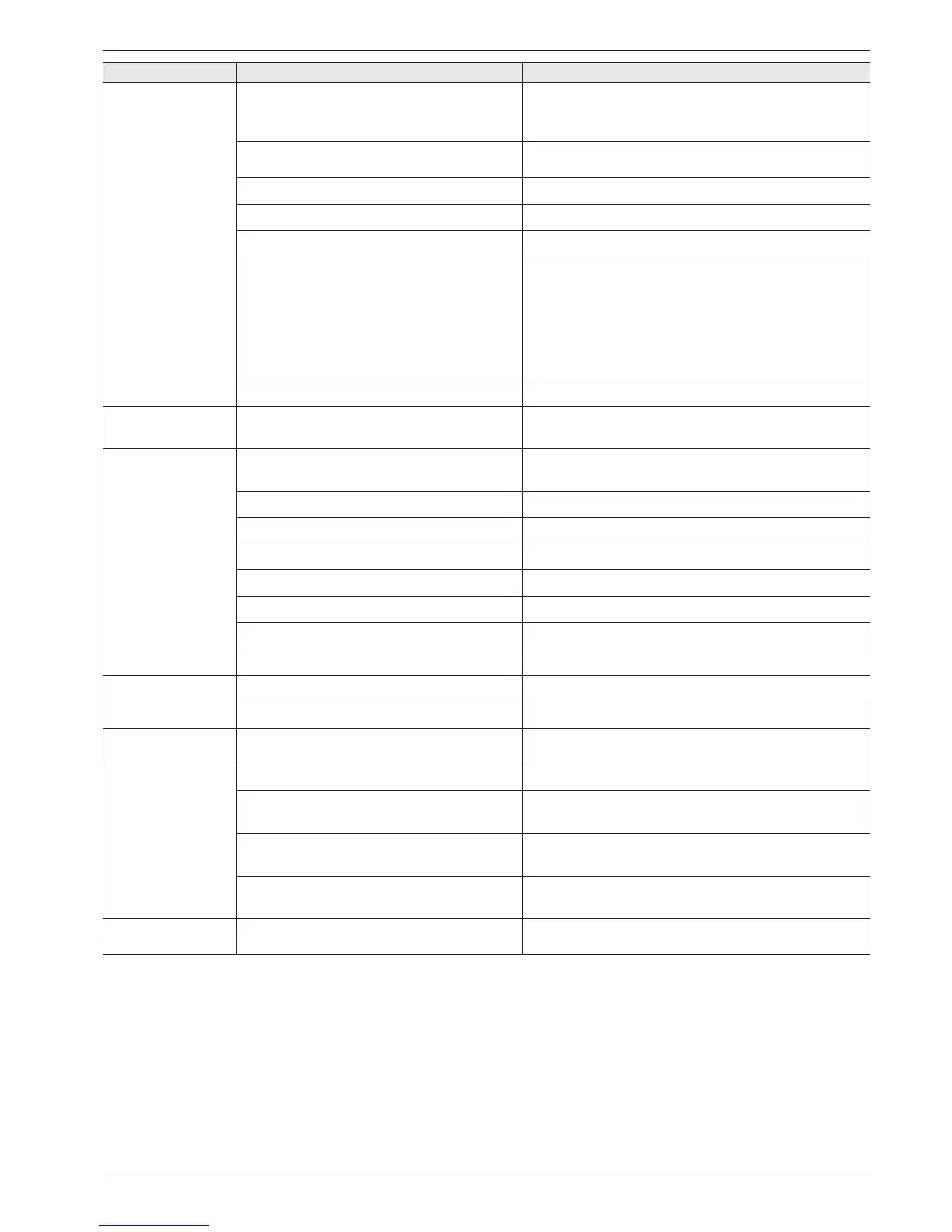

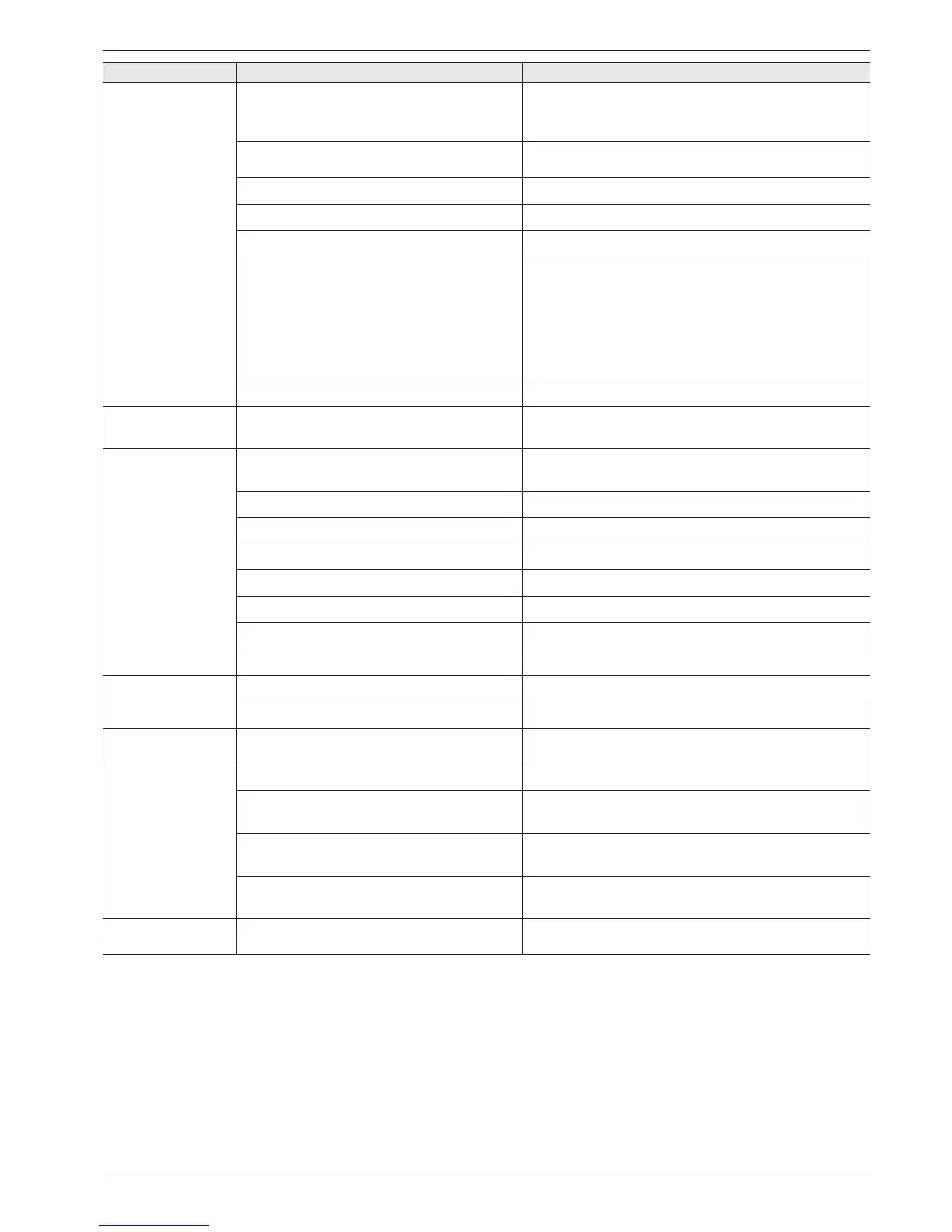

10 x Faults and malfunctions

FA ROTEX A1 BGe - 02/2014

51

1) See documentation "ROTEX RoCon BF Controller"

Tab. 10-1 Possible faults on the A1

Burner fan not run-

ning despite burner

demand

No mains voltage on burner

Ɣ Insert X1 plug on automatic firing until it clicks in place.

Ɣ Check voltage at the terminals L-N of the X1 plug

Ɣ Check/ renew fuse.

Plug connections switching panel PCB or auto-

matic firing are loose

Ɣ Check/ insert plug connections

Burner blower defective (bearing has seized)

Ɣ Replace the burner blower.

No gas pressure

Ɣ Inspect the gas connections.

Air in the gas line

Ɣ Vent the gas line.

Gas regulating block not opening

Ɣ Inspect the plug connection between the safety gas

regulation block valve and the automatic firing and

connect correctly if necessary.

Ɣ Check the safety gas regulation block (zero pressure

during ignition).

Ɣ Replacing the safety gas regulation block.

Ɣ Replace the combustion controller.

No ignition

Ɣ See "No ignition" fault

Burner starting is hard Start delay due to bad ignition

Ɣ Adjust ignition electrodes

Ɣ Check starting output and adapt if necessary.

No ignition Ignition electrodes short circuited

Ɣ Check the ignition electrodes and adjust or replace if

necessary.

Distance of ignition electrodes too large

Ɣ Check ignition electrodes and adjust if necessary.

Ignition electrodes contaminated or humid

Ɣ Clean ignition electrodes, and check burner setting.

Ignition electrodes burnt out

Ɣ Change ignition electrodes

Insulating body cracked

Ɣ Change ignition electrodes

Ignition transformer defective

Ɣ Replace ignition transformer

Ignition cable defective, flashovers

Ɣ Change ignition cable and determine the cause

Automatic firing unit faulty

Ɣ Replace the combustion controller.

Loud operating noises Wrong burner setting

Ɣ Correct burner setting.

Bearing damage on burner fan

Ɣ See fault "Loud, whistling mechanical noise".

Loud, whistling

mechanical noise

Burner blower bearing defective

Ɣ Replace the burner blower.

STL switch off Water throughput too low due to air inclusion

Ɣ Vent system

Water flow too low due to valves closing too

quickly along the entire heating network

Ɣ Use slow closing or timed valves, if needed, install

overflow valve

Pump standstill

Ɣ Check mains and PWM control signal connection,

replace pump if necessary.

Storage tank switched off in operation without

hot water storage tank

Ɣ Disconnect storage temperature sensor

Ɣ Switch off storage tank charging circuit

Flue gas temperature

sensor switch off

Flue gas temperature too high

Ɣ

Clean the boiler

Malfunction Possible cause Possible solution

Loading...

Loading...