23

4.3 Performance testing

It is recommended that the performance of your Sartorius Biohit pipettes

is checked regularly (e.g. every 3 months) and always after in-house

maintenance. A regular testing routine should be established by the users for

their pipettes having regard to the accuracy requirements of the application,

frequency of use, number of operators using the pipette, nature of the liquid

dispensed and the acceptable maximum permissible errors established by the

user (ISO 8655-1).

Performance tests should take place in a draught-free room at 15–30°C,

constant to ±0.5°C and relative humidity above 50%. The pipette, tips and

the test water should have stood in the test room for long enough (at least

2 hours) to reach equilibrium with the room conditions. Use distilled or de-

ionised water (ISO 3696, grade 3). Use an analytical balance with a readability

according ISO 8655-6.

Weighting

1. Adjust the desired test volume V

S

2. Carefully fit the tip onto the tip cone.

3. Fill the tip with test water and expel to waste five times to reach

humidity equillibrium in the dead air volume

4. Replace the tip. Pre-wet the tip by filling it once with the test water and

expell to waste.

5. Aspirate the test water, immersing the tip only 2-3 mm below the surface

of the water. Keep the pipette vertical.

6. Withdraw the pipette vertically and touch the tip against the side wall of

the test water container

7. Pipette the water into the weighting vessel, touching the tip against

the inside wall of the vessel just above the liquid surface at the angle of

30° to 45°. Withdraw the pipette by drawing one tip 8-10 mm along the

inner wall of the weighing vessel.

8. Read the weight in mgs (m

i

).

9. Repeat the tet cycle until 10 measurements have been recorded.

10. Convert the recorded masses (m

i

) to volumes (v

i

) by multiplying the mass

with the correction factor Z (Z-values in the table below): V

i

= m

i

Z

11. Calculatethemeanvolume(V)delivered:V=(ΣVi)/10

12. For conformity evaluation calculate the systematic error es of the

measurement:

in μl: e

S

= V – V

S

V

S

=selected test volume

or in %: e

S

= 100 (V – V

S

)/V

S

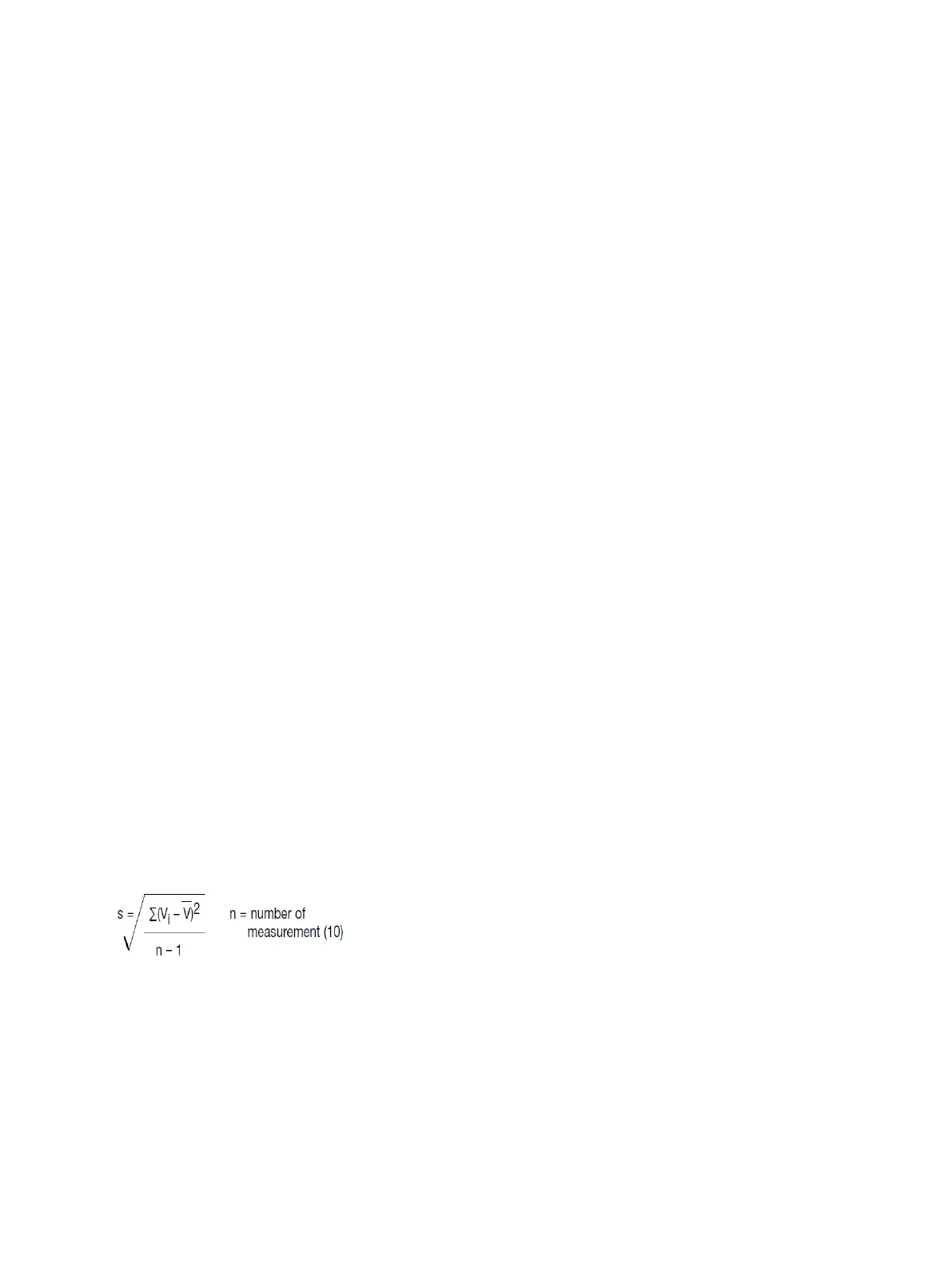

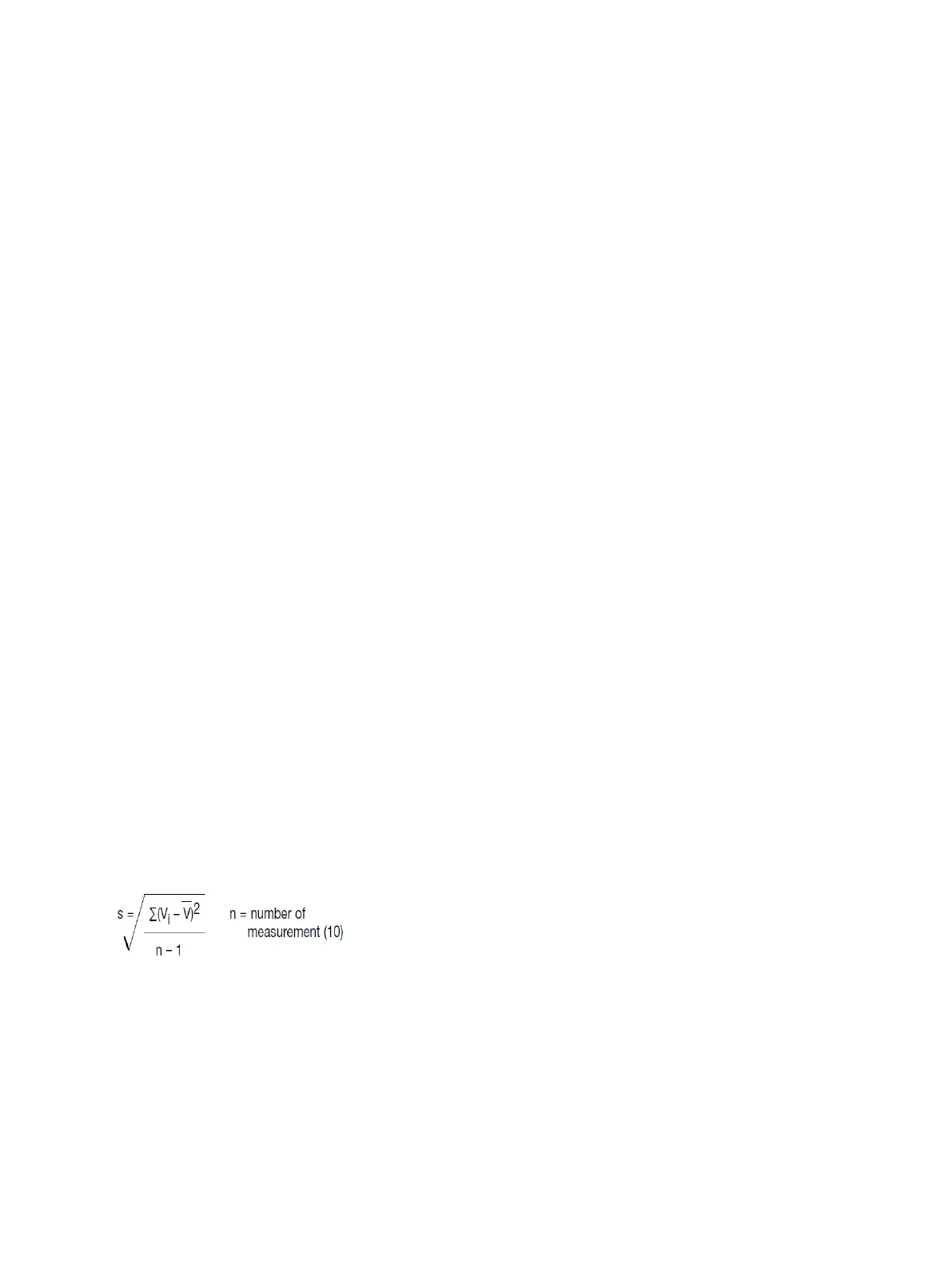

13. For conformity evaluation calculate the the random error of the

measurement:

as standard deviation:

or as coefficient of variation CV=100s/V

14. Compare the systematic error (inaccuracy) and random error

(imprecision) to the performance specification values of your own

laboratory.

Loading...

Loading...