19

The setpoint alarm register stores the status of the operated setpoints by setting the appropriate

bits to 1. The alarm status bits can be reset all together by writing zero to the setpoint alarm

register. It is possible to reset each alarm status bit separately by writing back the contents of

the alarm register with a corresponding alarm bit set to 0.

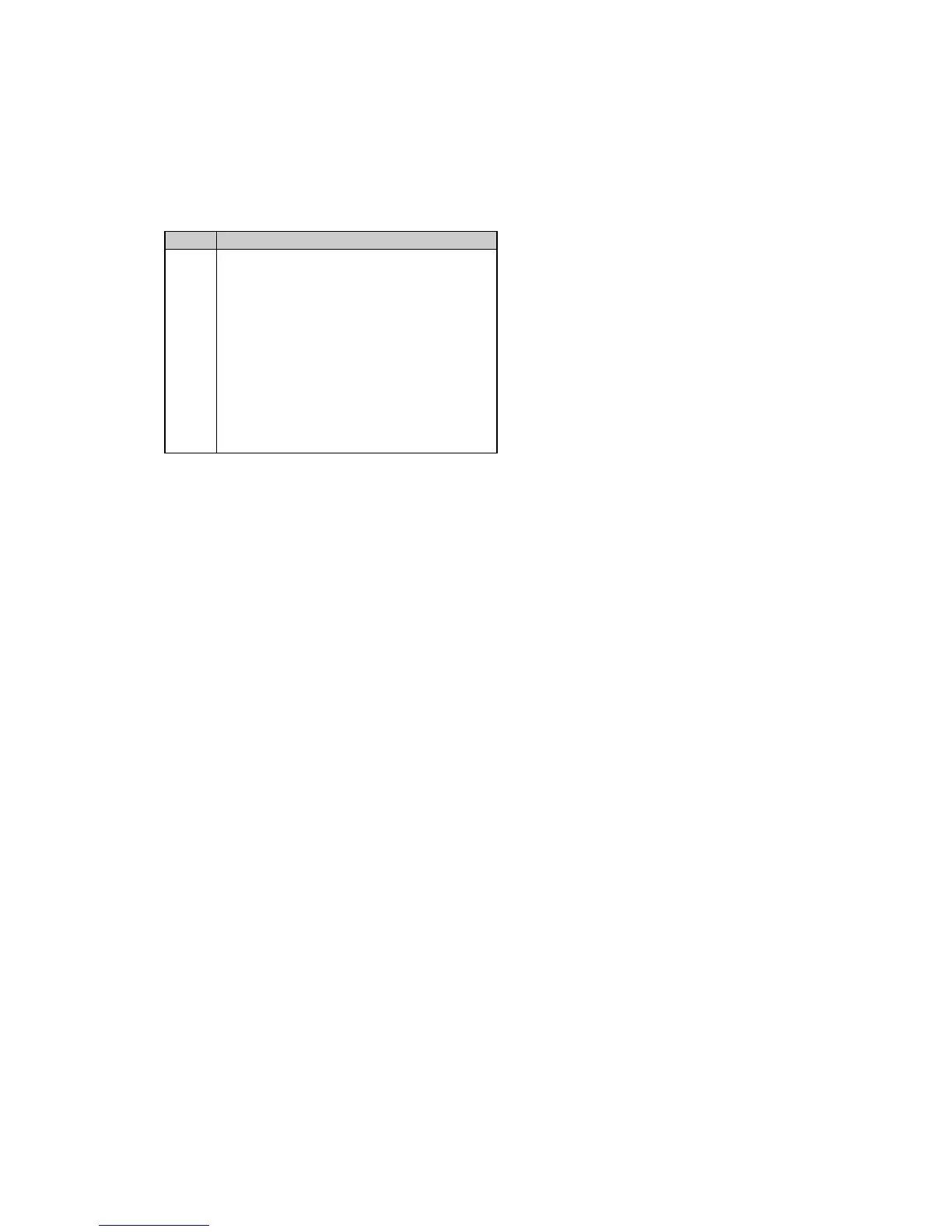

Table 5-14 Self-check Alarm Status

Bit Description

0

Reserved

1

ROM error

2

RAM error

3

Watchdog timer reset

4

Sampling failure

5

Out of control trap

6

Reserved

7

Timing failure

8

Loss of power (power up)

9

External reset (warm restart)

10 Configuration corrupted

11-15 Reserved

The self-check alarm register indicates possible problems with the instrument hardware or

setup configuration. The hardware problems are indicated by the appropriate bits which are set

whenever the instrument fails self-test diagnostics or in the event of loss of power. The setup

configuration problems are indicated by the dedicated bit which is set when either configuration

register is corrupted. In this event, the instrument will use the default configuration. The

configuration corrupt bit may also be set as a result of the legal changes in the setup

configuration since the instrument might implicitly change or clear other setups if they are

affected by the changes made.

Hardware fault bits can be reset by writing zero to the self-check alarm register. The

configuration corrupt status bit is also reset automatically when you change setup either via the

front panel or through communications.

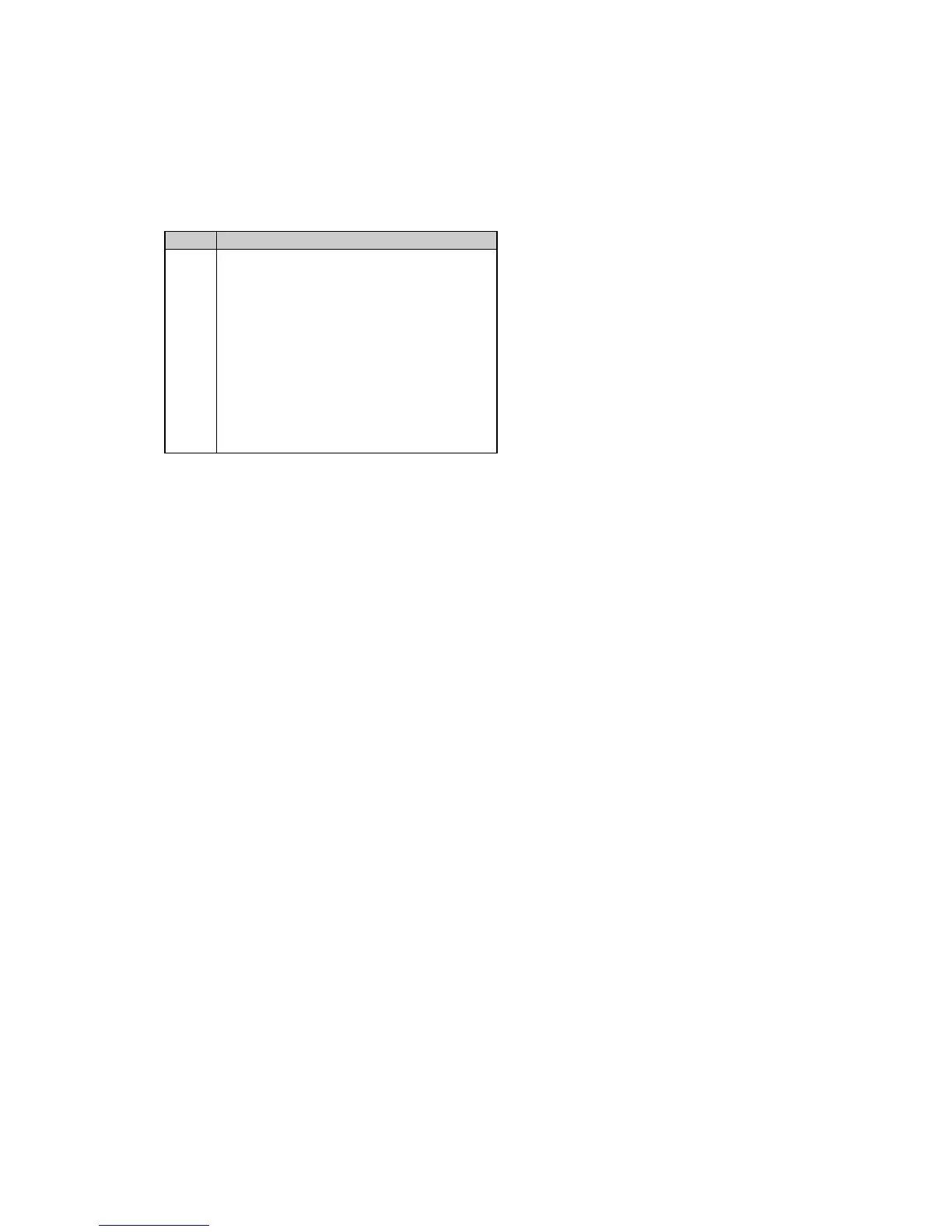

5.8 Extended Data Registers

The following table lists all registers containing the data measured by the instrument. Notice

that these registers are arranged into groups which are not located at adjacent addresses. You

can re-map these registers into adjacent addresses to access multiple data from different data

groups by using a single request. Refer to Section 2.9 for information on the user assignable

registers.

Along with the register address, the table shows for each data item its data identifier (ID). This

is a one word containing a data group ID in the high byte and the parameter offset in a group in

the low byte. Data IDs are used to specify input or output parameters whenever a data

parameter specification is needed, for example, when selecting analog output parameters or

reading Min/Max log records.

Loading...

Loading...