The coolant should be changed when the cooling

system is cleaned: every 6,000 hours or at least

every 5 years. See the section Changing the cool-

ant and cleaning the cooling system.

The coolant has several characteristics which are

important for the operation of the cooling sys-

tem:

• Corrosion inhibitor.

• Antifreeze.

• Increases the boiling point.

Scania recommends that the coolant used is a

mixture of water with antifreeze and corrosion

inhibitor (ethylene glycol). The coolant should

always contain 35-55% by volume of antifreeze

and corrosion inhibitor so that the coolant has the

correct properties for the cooling system to work.

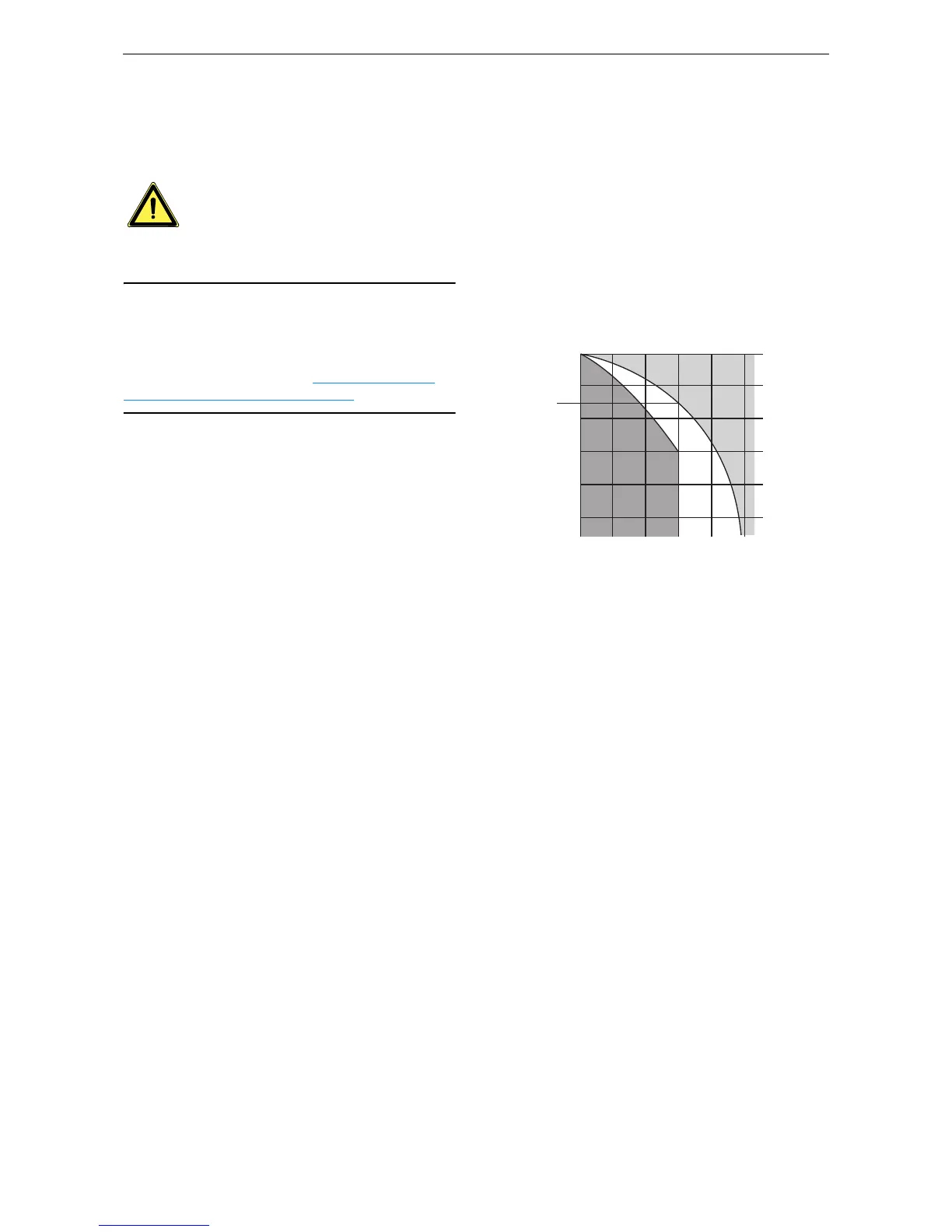

Coolant resistance to cold

The following example shows coolant properties

with 30 percent by volume of antifreeze and cor-

rosion inhibitor:

• Ice slush starts to form at -16°C (3°F).

• At -30°C (-22°F), there is a risk of cooling

system malfunction.

• There is no risk of damage by freezing with a

minimum antifreeze and corrosion inhibitor

content of 35 percent by volume.

The chart depicts coolant properties at different

percents of antifreeze and corrosion inhibitor

concentration by volume.

Curve A: Ice formation starts (ice slush)

Curve B: Damage by freezing occurs

Area 1: Safe area

Area 2: Malfunctions may occur (ice

slush)

Area 3: Risk of damage by freezing

Loading...

Loading...