INSTALLATION

MANUAL

SEAKEEPER 3 90378 4 3 of 5

Section 3: COOLING INSTALLATION

3.1 Precautions

• Installer is responsible for supplying a dedicated seawater pump and associated

plumbing. Seawater connections on the Seakeeper heat exchanger mate with ¾ inch

(19 mm) hose.

• The seawater output from the Seakeeper powers the seawater pump or central seawater

valve. This pump or valve must operate on 12 VDC and consume less than 3 amps.

Pumps requiring other voltages or higher current can still be controlled by using this

supply from the Seakeeper to trigger an installer-supplied contactor, but a separate

source of power must be provided.

• A self-priming seawater pump (customer/installer supplied) may be required due to

installation location to maintain water flow in all underway conditions where cavitation

near the intake may occur and potentially cause an air-lock condition restricting

seawater flow to the heat exchanger.

• Maximum allowed seawater pressure in heat exchanger is 20 psi (1.4 bar)

• Seawater flow requirement through heat exchanger is 2 GPM (7.6 LPM) minimum

and 6 GPM (22.7 LPM) maximum under all operating conditions of the boat. When

sizing seawater pump, installer should factor in losses for raw water plumbing. In

addition to initial operation at dock, new Seakeeper installations should be checked to be

within the flow requirements while vessel is at speed. Flows higher than 6 GPM (22.7

LPM) could affect heat exchanger life.

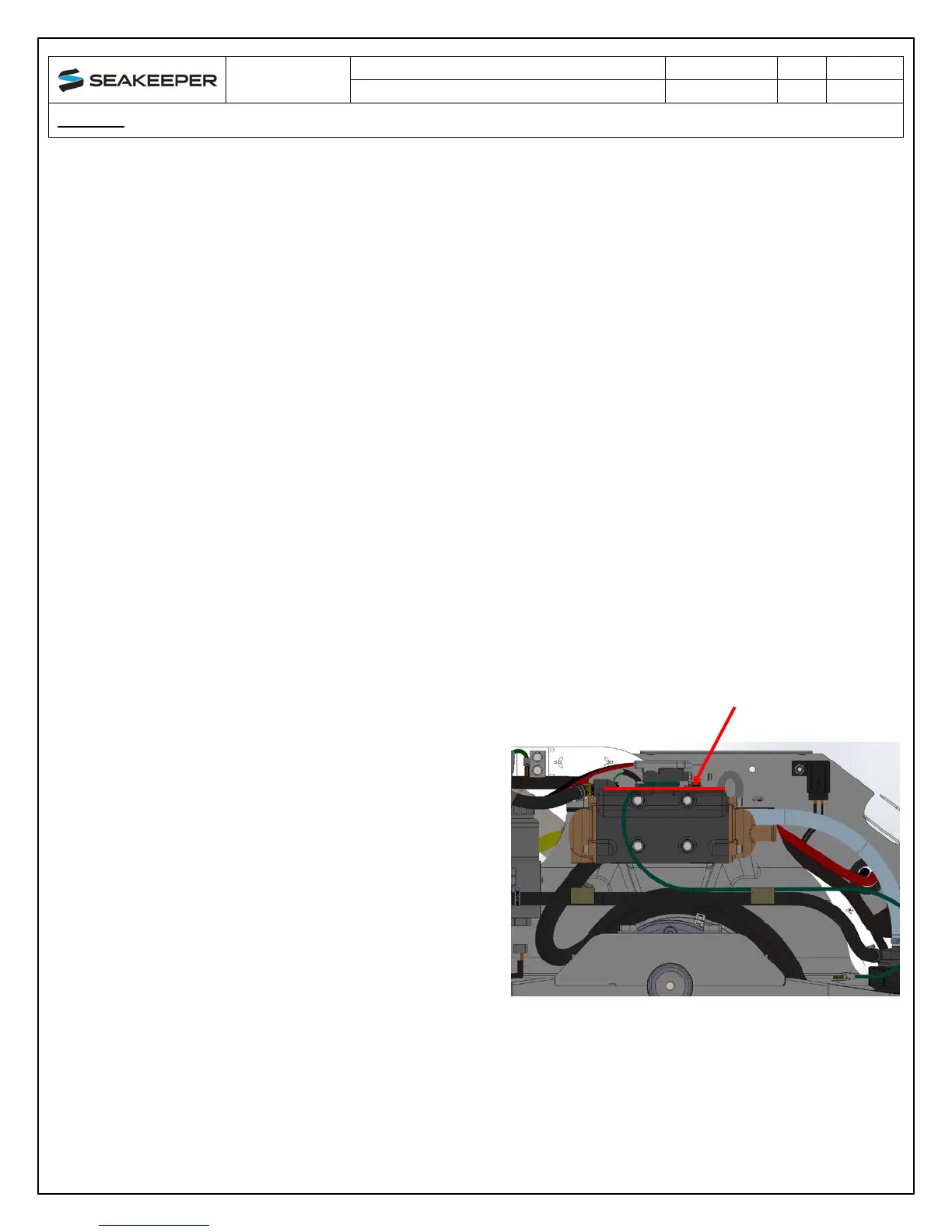

3.2 Adding Coolant

1) Cooling system is filled to proper level

when shipped, with a mixture of 50%

ethylene glycol and 50% distilled water.

Clear tube between thermostat housing

and reservoir should be filled with colored

coolant mixture. If level has dropped,

check for evidence of leaks at all

connections before adding fluid as

described below. If coolant is at the correct

level, skip to seawater connection in

section 3.3.

FIGURE 3 – SEAKEEPER 3 COOLANT LEVEL

Loading...

Loading...