INSTALLATION

MANUAL

SEAKEEPER 3 90378 4 4 of 5

Section 3: COOLING INSTALLATION

2) Mix 50% ethylene glycol with 50% distilled water in a clean container. Refer to Table 1

or glycol manufacturer’s literature for freezing points. It is required that ethylene glycol with

corrosion inhibitors be used. Most commercially available glycol has these additives standard.

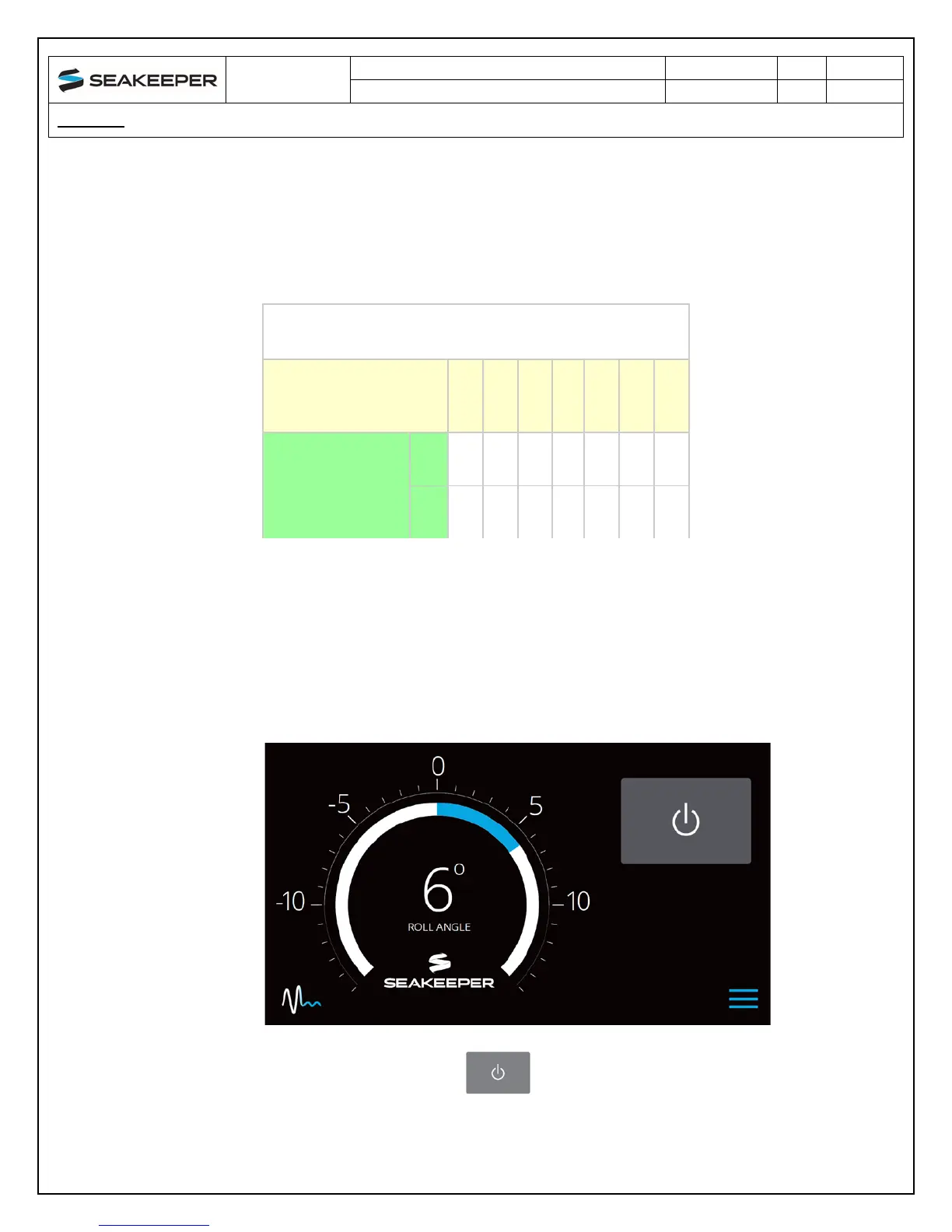

Table 1: Freezing Point

Ethylene Glycol Solution

(% by volume)

0 10 20 30 40 50 60

Temperature

(

o

F) 32 23 14 2 -13 -36 -70

(

o

C) 0 -3 -8 -16 -25 -37 -55

3) Remove pressure cap on top of reservoir. Pour mixture in until level reaches top face of

the heat exchanger as shown in Figure 3. Filling reservoir above this level will not cause

any damage but coolant may be expelled from pressure relief port below cap due to

normal thermal expansion of coolant.

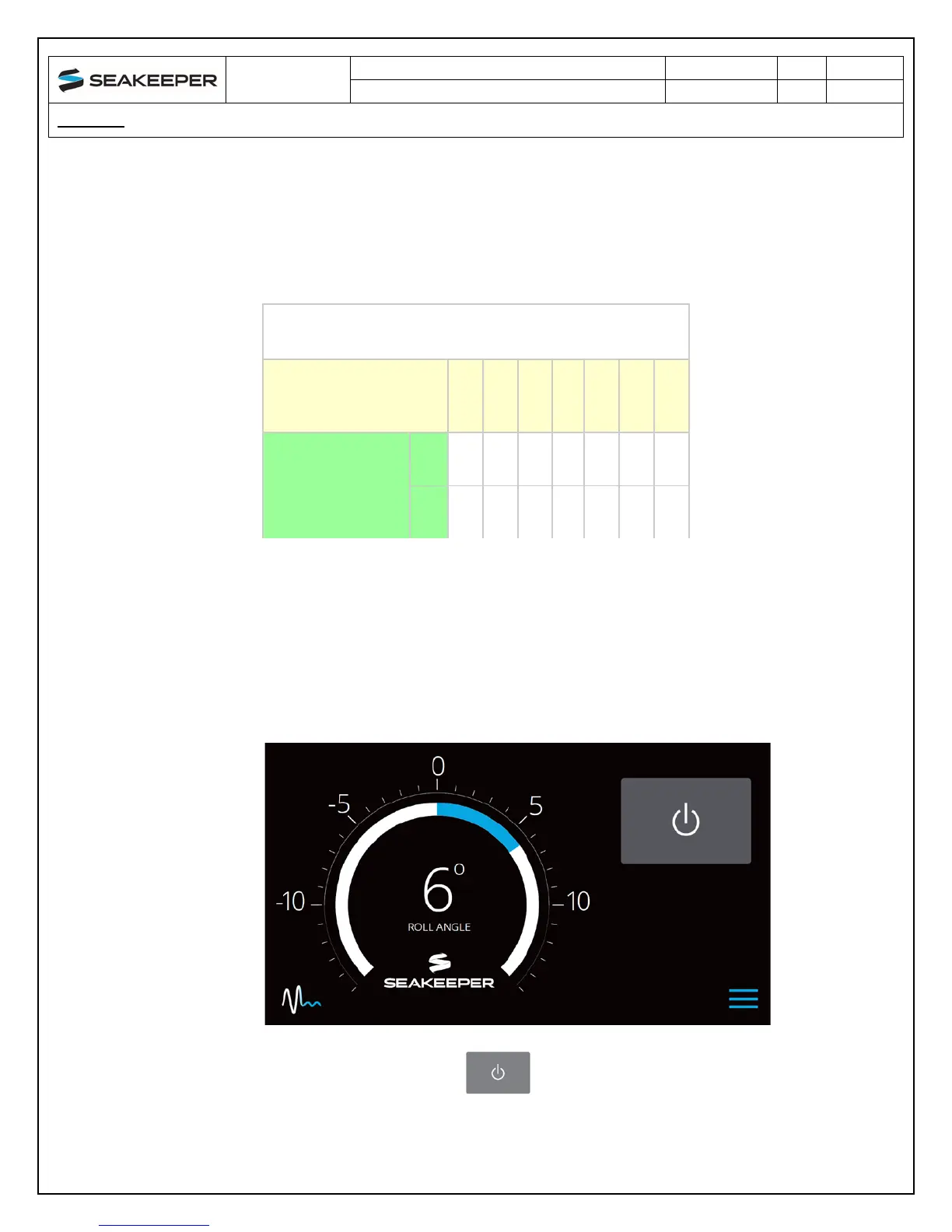

4) Connect 12 V to controller.

• At the Display check for any ALARMS

• Press the POWER ON/OFF button

• The flywheel will start to spin and the glycol pump will start.

Loading...

Loading...