43

42

0.0~15.0%

P4-07

Default:

5.0

Torque upgrade

This parameter can make compensation for output voltage when

converter is running in a low frequency, so that the characteristics of low-

frequency torque which is controlled by V/F can be compensated and

upgraded.

If the setting of torque upgrade is too high, not only motor tends to be

overheated but also over current may be caused by it. In general, the setting

of torque upgrade must be no more than 10%. To prevent converter from over

current effectively, this parameter must be adjusted properly. This parameter

should be increased whenever there is heavy load; otherwise, please

decrease this parameter.

• The practical slip of motor varies from load to load. Output frequency can

be adjusted automatically according to the condition of loading by this

functional parameter, so that compensation can be made for the influence of

load on rotational speed of motor.

0.0~10.0Hz

P4-08

Default:

0.0Hz

Slip

compensation

• AVR function is also known as Automatic Voltage Regulation function.

Adjustment will be made automatically to stabilize output voltage whenever

there is fluctuation of input voltage, so that it can prevent converter from

overheat of motor caused by high output voltage or poor performance

caused by low output voltage.

P4-09

Default: 0

AVR

function

0 : Disabled

1 : always enabled

2 : only enabled in process of

deceleration

0:Disabled

1:Enabled

P4-10

Default: 0

Energy-efficient

running

• During the process of no-load or light-load running, output voltage can be adjusted

properly to achieve automatic energy conservation by detecting load current. This

parameter is applicable to the load of draught fan or pump.

• Multiple-phase V/F curves can be defined by these six parameters

above (P4-01~ P4-06)

The set value of V/F curves is generally set according to the load

characteristics of motor.

0.0Hz~P4-03 (Intermediate frequency 2)

0~ rated voltage (P3-00)

P4-01(Intermediate frequency 1)~P4-05

(Intermediate frequency)

0~ rated voltage (P3-01)

P4-03 (Intermediate frequency 2) ~

P3-00 (rated frequency)

0~ rated voltage (P3-01)

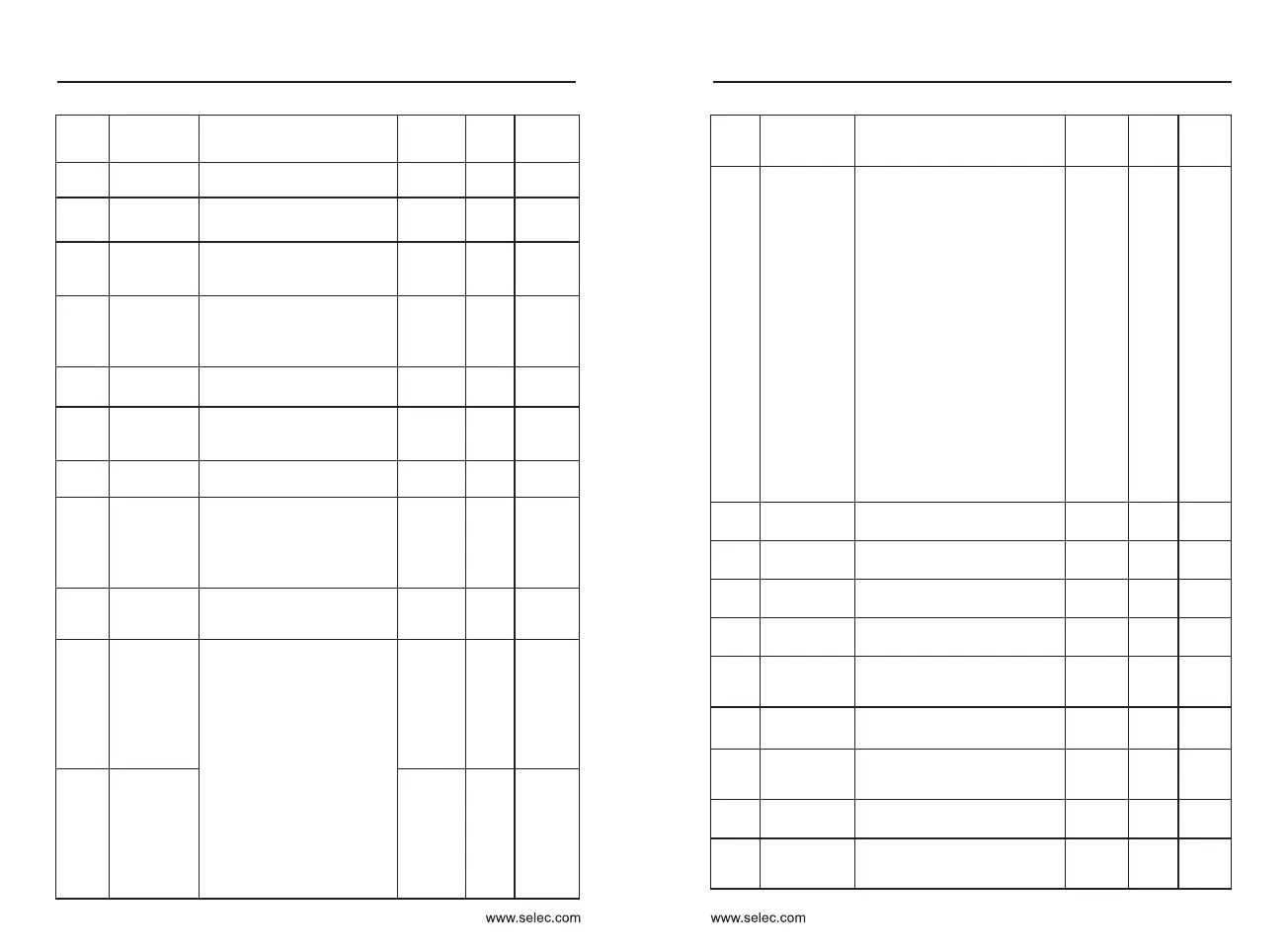

P4-01

Default:

1.0Hz

V/F Intermediate

frequency 1

P4-02

P4-03

P4-04

P4-05

P4-06

V/F Intermediate

voltage 1

V/F Intermediate

frequency 2

V/F Intermediate

voltage 2

V/F Intermediate

frequency 3

V/F Intermediate

voltage 3

Default:

5V

Default:

5.0Hz

Default:

25V

Default:

25.0Hz

Default:

115V

Precaution : motor may be overheated or even burned if preset low-

frequency voltage is too high, which may activate its over current protection.

V1<V2<V3, F1<F2<F3.

Voltage

V

Vb

V3

V2

V1

F1

F2

F3

Fb

Frequency Hz

5 : Self-adaptive control can be applied to running regulation by adapting itself to actual

load automatically, which is applicable to the operating situations which require greater

low-frequency torque as well as strict control on speed.

3 : high starting torque V/F is applicable to the operating situations which require higher

starting torque.

4 : Self-setting V/F indicates that V/F curve can be preset randomly by the functional

codes P4-01~P4-06, which is applicable to the operation with special load, for example

dewaterer or centrifuge, etc.

Parameters must be set correctly according to the information of nameplate on the motor

if this function needs to be enabled; it's only when the capacity of the motor is the same

as that of this converter can its performance be improved greatly.

P9-05

Overcurrent

stall gain

0–100 20

P9-06

Overcurrent

stall protective

current

100%–200% 150%

P9-07

Short-circuit to

ground upon

power-on

1

P9-08

Brake unit

action starting

voltage

200.0~2000.0V

P9-09

Fault auto

reset times

0〜20 0

P9-10

DO action

during fault

auto reset

0

P9-11

Fault auto

reset interval

0.1s〜100.0s 1.0s

P9-12

Input phase

loss protection

/contactor

energizing

protection

selection

11

P9-13

Output phase

loss protection

selection

0 : Disabled

1 : Enabled

1

P9-14

First failure

type

×

P9-15

Second failure

type

P9-16

Third

(most recent)

fault type

P9-17

Frequency at

the third failure

P9-18

Current at

the third fault

P9-19

Bus voltage at

the third fault

P9-20

Third fault input

terminal status

P9-21

Third fault

output

terminal status

P9-22

Inverter status

at the third fault

P9-23

Power-on time

during the

third fault

P9-24

Run time at

the third fault

P9-27

Frequency at

the second

failure

Parameter

Name

Setting Range

Default

Prope-

rty

Modbus

Address

Fun-

ction

Code

0 : Invalid

1 : Valid

0 : no act

1 : act

Ones place : Input phase loss

protection option

Tens place : Contactor suction

protection option

0: Disabled 1: Enabled

-

×

-

0 : no fault 1: Reserved

2 : accelerated overcurrent

3 : Deceleration over current

4 : Constant speed over current

5 : Accelerated overvoltage

6 : Deceleration overvoltage

7 : Constant speed overvoltage

8 : Buffer resistor overload

9 : Under voltage

10 : Inverter overload

11 : Motor overload

12 : Input phase loss

13 : Output phase loss

14 : Module overheating

15 : External fault

16 : Communication error

17 : Contactor abnormality

18 : Abnormal current detection

19 : Tuning error

20 : PG card is abnormal

21 : Parameter read & write error

22 : Inverter hardware is

abnormal

23 : Motor short circuit to ground

24 : Reserved

26 : Run time arrives

27 : User Defined Fault 1

28 : User-defined fault 2

29 : Power on time arrives

30 : Offload

31 : Loss of PID feedback at

runtime

40 : Fast current limit timeout

41 : Switching motor during

operation

42 : Speed deviation is too large

43 : Motor overspeed

45 : Motor overheating

51 : Initial position error

Fun-

ction

Code

Parameter

Name

Setting range

Default

Prope-

rty

Modbus

Address

×

-

- -

×

- -

×

- -

×

- -

×

- -

×

- -

×

- -

×

- -

×

- -

×

User Manual

Chapter 5

User Manual

Chapter 5

○

○

○

○

○

○

○

○

○

63750

63751

63752

63753

63754

63755

63756

63757

63758

63759

63760

63761

63762

63763

63764

63765

63766

63767

63768

63769

63772

690

Loading...

Loading...