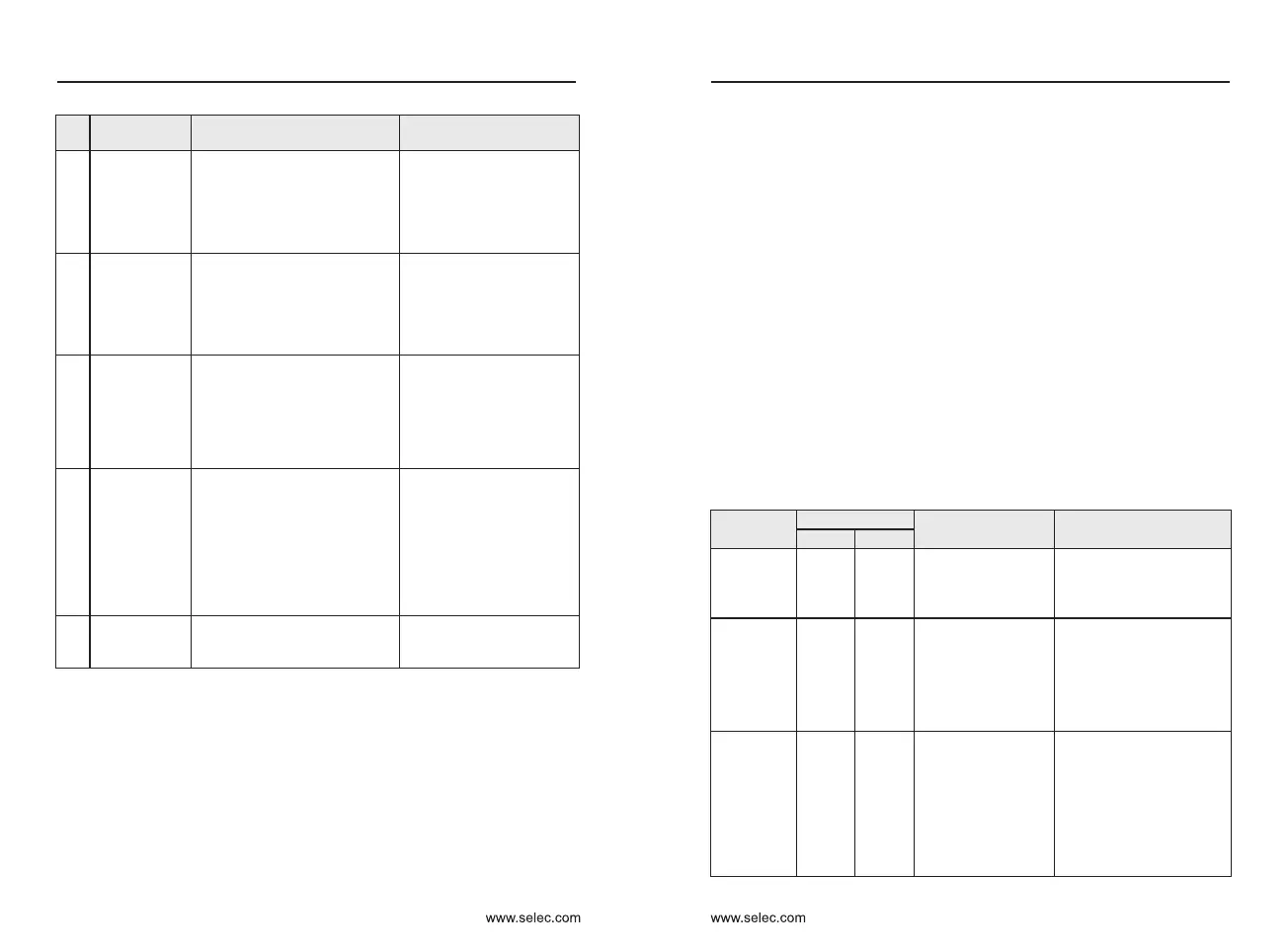

7

The input

terminals are

disabled.

8

The motor

speed is

always low

in CLVC

mode.

9

The inverter

reports

overcurrent

and over-

voltage

frequently.

10

Err17 is

reported

upon power-

on or running.

The soft startup contactor is

not picked up.

11

8.8.8.8.8. Is

displayed

upon power-on.

Related component on the

control board is damaged.

Replace the control board.

1: The parameters are set

incorrectly.

2: The external signal is

incorrect.

3: The control board is faulty.

1: Check and reset the

parameters in group P4.

2: Re-connect the external

signal cables.

3: Contact the agent or

company to support.

No.

Solutions

Fault

phenomenon

Possible Causes

1: The encoder is faulty.

2: The encoder cable is

connected incorrectly or in poor

contact.

3: The PG card is faulty.

4: The driver board is faulty.

1: The motor parameters are

set improperly.

2: The acceleration/deceleration

time is improper.

3: The load fluctuates.

1: Replace the encoder &

ensure the cabling is

proper.

2: Replace the PG card.

3: Contact the agent or

company to support.

1: Re-set motor parameters

or re-perform the motor

auto-tuning.

2: Set proper acceleration

deceleration time.

3: Contact the agent or

company to support.

1: Check whether the

contactor cable is loose.

2: Check whether the

contactor is faulty.

3: Check whether 24 V

power supply of the

contactor is faulty.

4: Contact the agent or

company to support.

8-1 Maintenance

INSPECTION AND MAINTENANCE

Inspection and maintenance of the inverter requires professional and

qualified personnel, and pay attention to the following matters:

• Maintenance personnel must follow the specified methods of

maintenance and maintenance.

• The power of the inverter must be turned off for 5 minutes before

maintenance.

• Do not directly touch the components on the PCB, otherwise it will be

easily damaged by static electricity.

• After maintenance is complete, you must confirm that all screws are

tightened.

Due to the influence of the environment (such as temperature, humidity,

smoke, etc.) of the inverter and the aging of components inside the inverter,

various faults may occur in the inverter. Therefore, the inverter must be

inspected daily and regularly maintained during storage and use. Daily

inspection and maintenance refer to the following table:

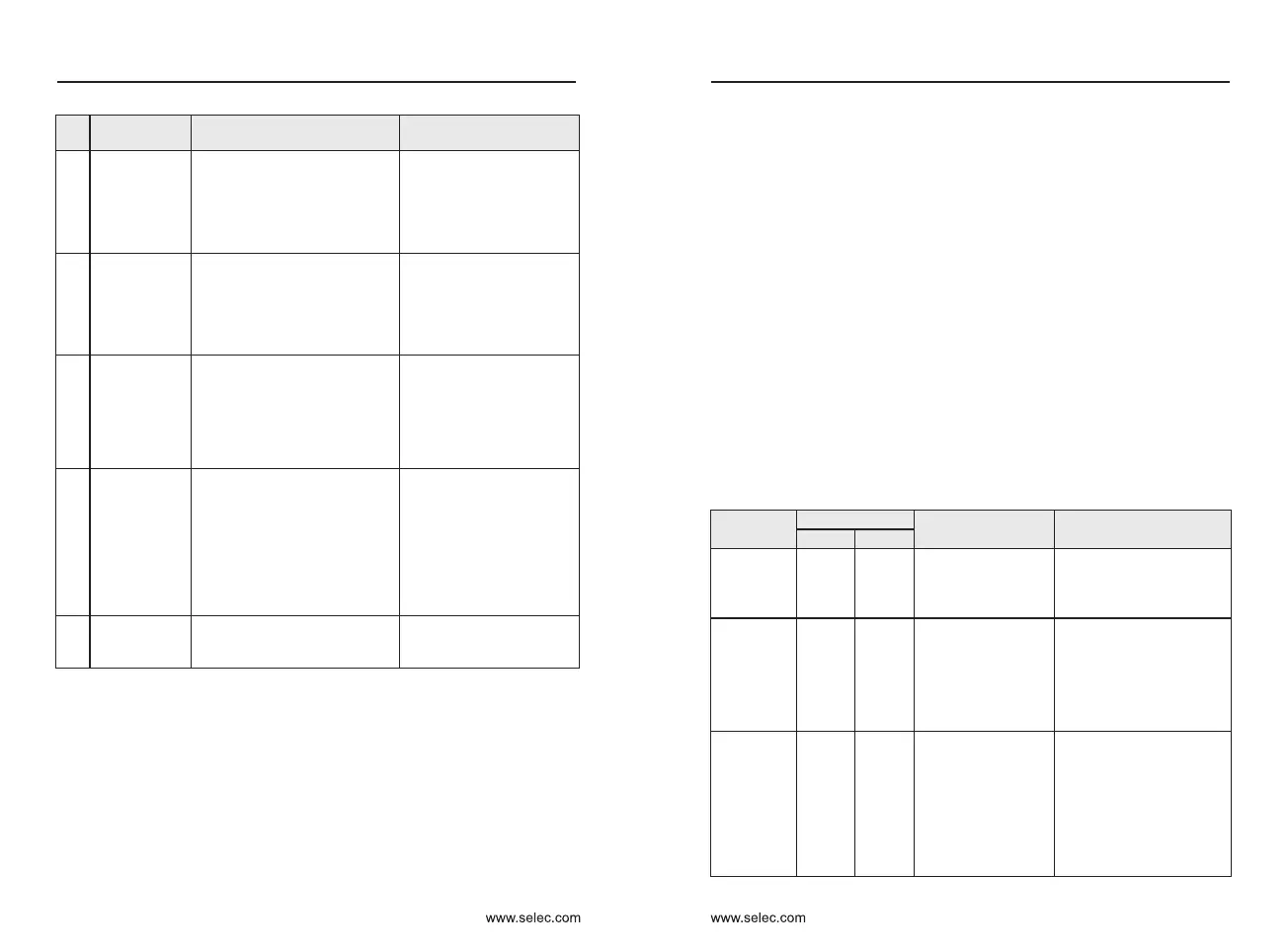

Operating

environ-

ment

Frequency

converter

1. Temperature,

humidity

2. Dust, moisture

3. Gas

1. Temperature <50 ° C,

humidity < 90%,

2. No frost, no odor, no

flammable, explosive gas

Cooling

system

1. Installation

environment

2. Inverter body fan

1. The installation

environment is well

ventilated and the air duct

is non-blocking

2. The main body fan

works normally without

abnormal noise

1.Vibration,

temperature rise

2. Noise

3. Internal dust,

stolen goods

4. Wires, terminals

1. Smooth vibration,

normal air outlet

temperature

2. No abnormal noise,

no odor

3. Completely remove

with dry compressed air

4. The fastening screws

are not loose

User Manual

166

User Manual

167

Check

issues

Inspection cycle

Anytime Regular

Check content Criteria and maintenance

ü

ü

ü

Chapter 7

Chapter 8

Loading...

Loading...