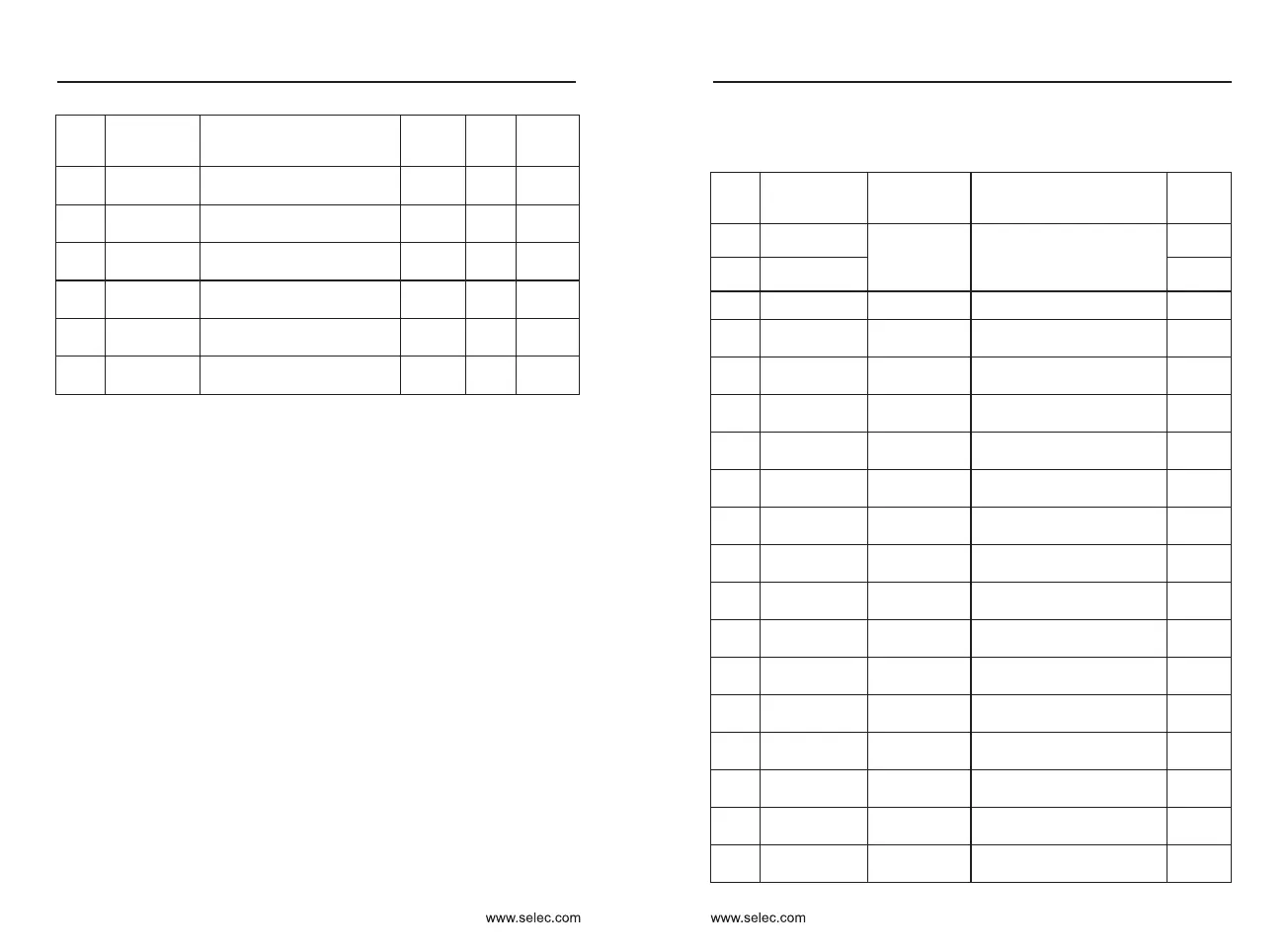

7 6 5 4 3 2 1 0

Parameter values = bit7×2 +bit6×2 +bit5×2 +bit4×2 +bit3×2 +bit2×2 +bit1×2 +bit0×2

7 6 5 4 3 2 1 0

=0×2 +1×2 +0×2 +0×2 +1×2 +0×2 +1×2 +0×2

=0+64+0+0+8+0+2+0

=74

Namely (01001010)2 = (74)10

Hence P8-17 should be set as 74

It’s mainly applied to the setting of Acc/Dec time for each program,

which is preset by binary mode (16 bit). Parameter can be entered only after

the binary value is converted into decimal value.

Take the following settings for example:

Parameter values= (0000000011100100) = (228)

2 10

Hence the P8-18should be set as 228

P9 : Protection Function parameters

These two parameters are mainly applied to the setting of real-

time relay protection of load motor. Effective thermal protection of motor

can be achieved by setting this parameter correctly when rated current of

motor is not matched with rated current of converter. Critical point of

overload protection (motor) = (allowed max. load current / rated current of

motor) * 100%

Timing for each

program's Acc-Dec

Default: 0

P8-18

0~65535

BIT 0~15 indicates the ACC/DEC

time of 0~7

Options for

overload protection

Default: 0

P9-00

0 : Disabled

1 : Enabled

Critical point of

overload protection

Default:

110%

P9-01

50~120%

0

12

3

4

5

6

7

8

9

10

1112

13

14

15

0 0 0 0 0 0 0 0 1 1 1 0 0 1 0 0

15

2

14

2

13

2

12

2

11

2

10

2

9

2

8

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

2

Acc/Dec Time 0 of Principal Frequency

Acc/Dec time 1 of first program

Acc/Dec time 2 of first program

Acc/Dec time 3 of first program

Acc/Dec time 0 of first program

Acc/Dec time 0 of first program

Acc/Dec time 0 of first program

Acc/Dec time 0 of first program

Weighted value

Binary set value

BIT

Over voltage protection function will be enabled so that the

decreasing output frequency of converter can be slowed down if bus voltage

detected by converter while running exceeds the critical point of over voltage

defined by parameter P9-03(in comparison with standard bus voltage); if it’s

detected that the bus voltage is lower than the critical point, converter will

continue to decelerate again.

Due to the influence of inertia load, actual droop rate of motor’s

rotational speed may be lower than droop rate of output frequency while

converter is decelerating; meanwhile, electrodes may feedback electric

energy to converter, which may raise the bus voltage of converter. If no action

is taken in time, stripping may be caused by over voltage of busbar.

Because of excessive load, actual rate of rotational speed rise of

motor may be lower than the rate of output frequency rise while converter is

decelerating; if no action is taken in time, stripping may be caused by over

current.

Over-current protection function will be enabled so that increasing

output frequency of converter can be slowed down if bus current detected by

converter while running exceeds the critical point of over current defined by

parameter P9-05; if it’s detected that output current is lower than the critical

point, converter will continue to accelerate again.

Phase-failure protection of input: options are selected to enable or disable

phase-failure protection for input Phase-failure protection of output: options

are selected to enable or disable phase-failure protection for output

Overload

protection

Default: 1

P9-02

0 : Disabled

1 : Enabled

Critical point of

Over voltage

Default:

118

P9-03

110.0~150.0%

Over current

protection

Default: 1

P9-04

0 : Disabled

1 : Enabled

Critical point of

over-current

Default:

180

P9-05

100~180%

Phase-failure

protection of input

Default: 0

P9-06

0 : Disabled

1 : Enabled

Phase-failure

protection of output

P9-07

0 : Disabled

1 : Enabled

Default: 0

61

60

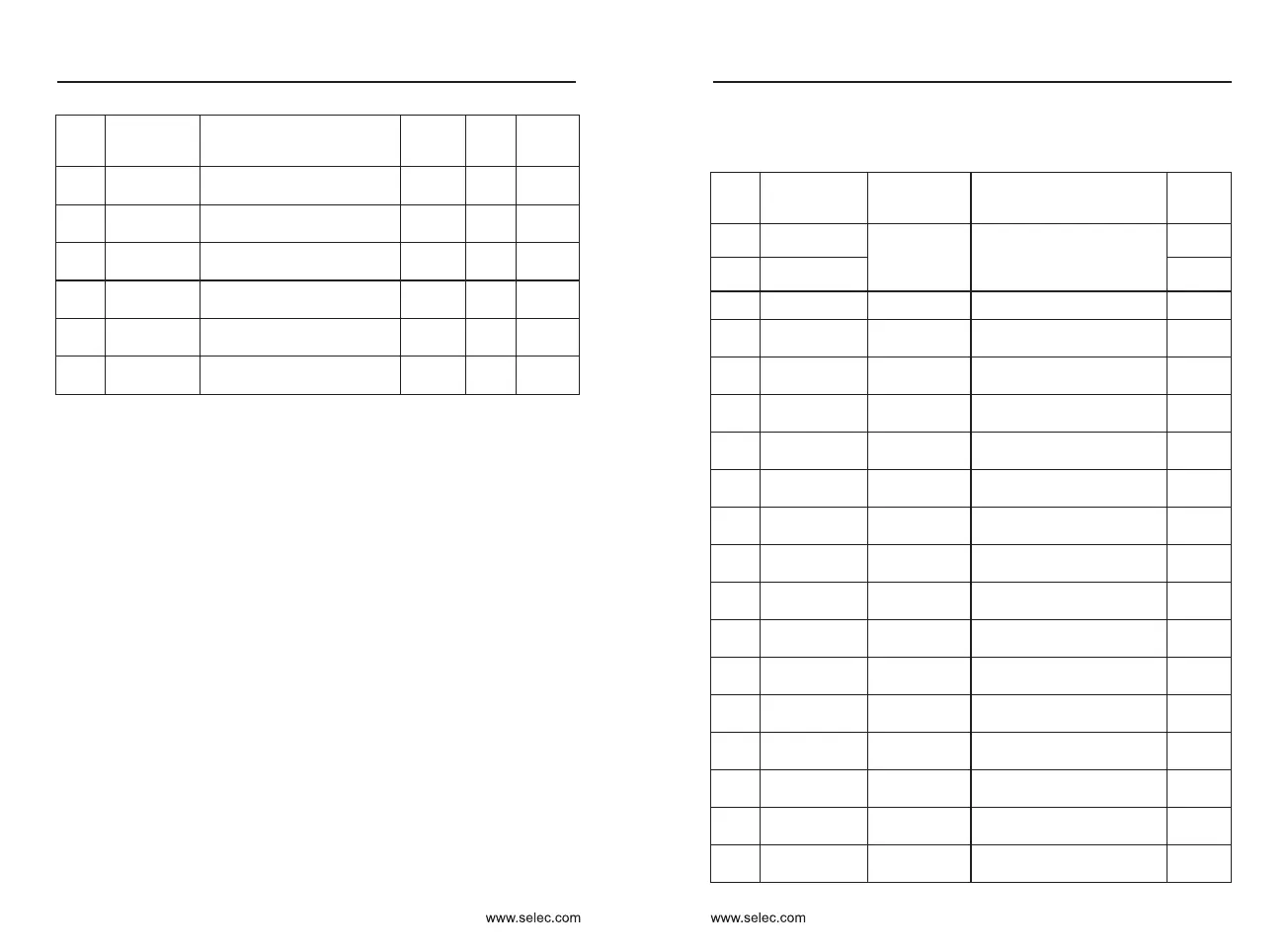

Fun-

ction

Code

Parameter

Name

Setting range

Default

Prope-

rty

AC-14

AO1 target

voltage 2

6.000V 〜 9.999V

factory

reset

AC-15

AO1 measured

voltage 2

6.000V 〜 9.999V

AC-16

AO2 target

voltage 1

0.500V 〜 4.000V

AC-17

AO2 measured

voltage 1

0.500V 〜 4.000V

AC-18

AO2 target

voltage 2

6.000V 〜 9.999V

AC-19

AO2 measured

voltage 2

6.000V 〜 9.999V

Modbus

Address

factory

reset

factory

reset

factory

reset

factory

reset

factory

reset

AC-20

AI2 measured

current 1

0.000mA 〜 20.000mA

AC-21

AI2 sampling

current 1

0.000mA 〜 20.000mA

AC-22

AI2 measured

current 2

0.000mA 〜 20.000mA

AC-23

AI2 sampling

current 2

0.000mA 〜 20.000mA

AC-24

AO1 ideal

current 1

0.000mA 〜 20.000mA

AC-25

AO1 measured

current 1

0.000mA 〜 20.000mA

AC-26

AO1 ideal

current 2

0.000mA 〜 20.000mA

AC-27

AO1 measured

current 2

0.000mA 〜 20.000mA

factory

reset

factory

reset

factory

reset

factory

reset

factory

reset

factory

reset

factory

reset

factory

reset

5-2 Monitoring parameter

U0 Group Basic monitoring parameter

Fun-

ction

Code

Parameter

Name

Display range

Instruction

U0-00

Running

frequency

0.01~320.00Hz

Display operating frequency

and set frequency (Hz)

U0-01

Set frequency

U0-02

Bus voltage

0.0~3000.0V

Display bus voltage (V)

U0-03

Output voltage

0~1140V

Display inverter output voltage

(V)

U0-04

Output current

0.0~6553.5A

Display inverter output current

(A)

U0-05

Output Power

0~32767kW

Display inverter output power

(kW)

U0-06

Output torque

-200.0~200.0%

Display inverter output torque

during operation

U0-07

Input terminal

status

0~32767

Input status: X1~X9

corresponds to Bit0~Bit8

U0-08

Output terminal

status

0~1023

Output terminal status: Y2,

relay,

U0-09

AI1 voltage

0.01V

Y1 corresponds to Bit0, Bit1,

Bit3

U0-10

AI2 voltage

0.01V

Display input AI1 voltage (V)

U0-11

AI3 voltage

0.01V

Display input AI2 voltage (V)

U0-12

Count value

0~65535

Display input AI3 voltage (V)

U0-13

Length value

0~65535

Display count value

U0-14

Load speed

display

0~65535

Display length value

U0-15

PID setting

0~65535

Display load speed

U0-16

PID feedback

value

0~65535

Display PID settings

U0-17

PLC stage

0~16

Display PLC operation phase

User Manual

Chapter 5

User Manual

Chapter 5

○

○

○

○

○

○

44047

44048

44049

44050

44051

44052

28673

28674

28675

28676

28677

28678

28679

28680

28681

28682

28683

28684

28685

28686

28687

28688

28689

28690

Modbus

Address

-10.00V 〜 +10.00V

-10.00V 〜 +10.00V

-10.00V 〜 +10.00V

-10.00V 〜 +10.00V

-10.00V 〜 +10.00V

-10.00V 〜 +10.00V

Loading...

Loading...