User Manual

140

User Manual

141

When the PID given changes, the PID set value changes linearly

according to the given change time, which reduces the adverse effect of the

given sudden change on the system.

PID given change time, refers to the time required for the PID reference

value to change from 0.0% to 100.0%.

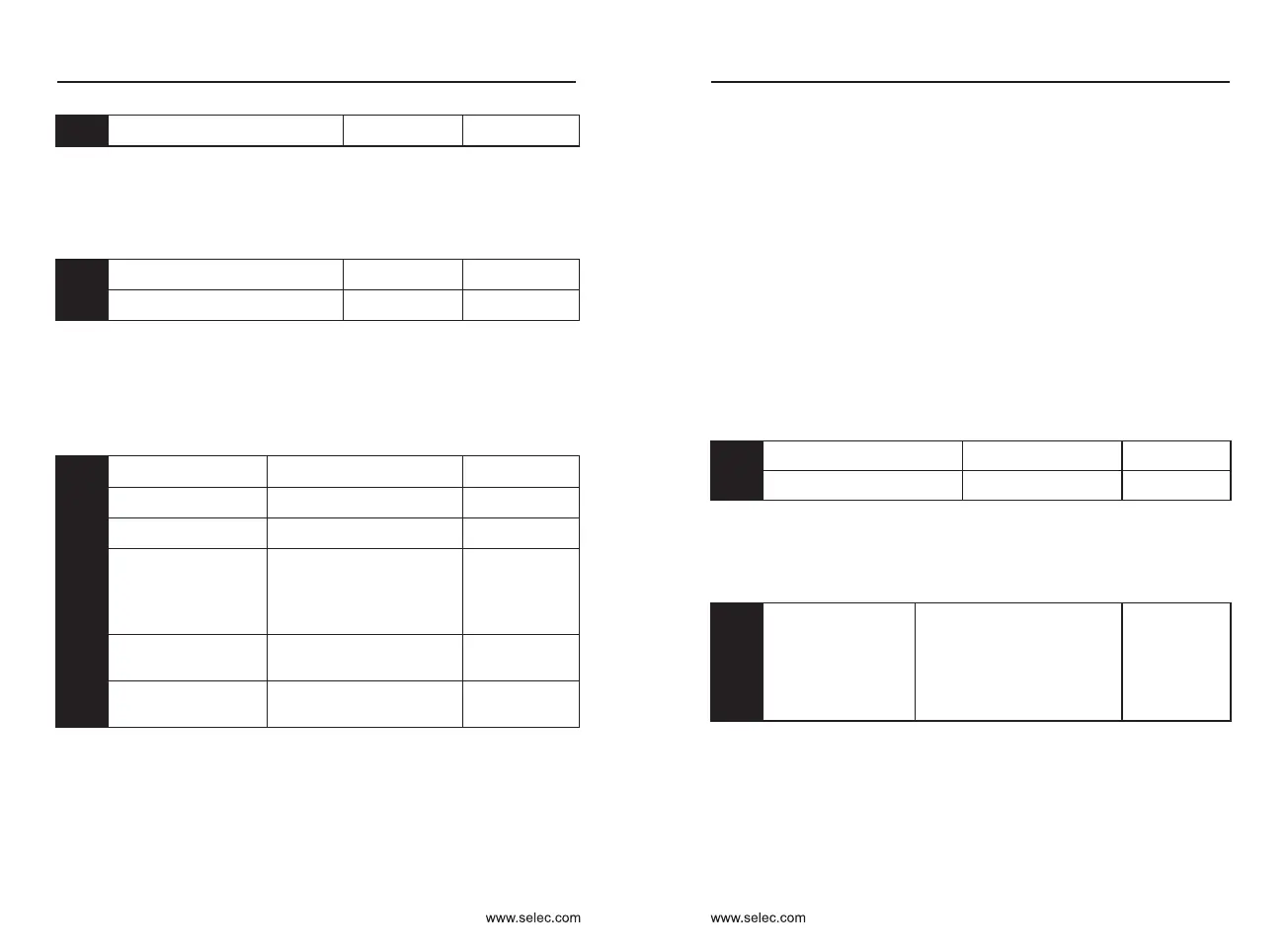

PA-11

PID given change time

Default:0.00s

0.00~650.00s

PA-12

PID feedback filter time

Default0.00s

0.00~60.00s

PA-13

PID output filtering time

Default0.00s

0.00~60.00s

PA-12 is used to filter the amount of PID feedback. This filtering helps to

reduce the influence of feedback on the feedback, but it will bring the

response performance of the process closed-loop system.

PA-13 is used to filter the PID output frequency, which will attenuate the

sudden change of the inverter output frequency, but it will also bring the

response performance of the process closed-loop system.

PA-15

Proportional gain Kp2

Default:20.0

0.0~100.0

PA-16

Integration time Ti2

Default : 2.00s

0.01s~10.00s

PA-17

Derivative time Td2 Default : 0.000s

0.01s~10.000s

PA-18

PID parameter

switchover condition

Default : 0

0: No switchover

1: Switchover via the

input terminal

2: Automatic switchover

based on deviation

PA-19

PID parameter

switchover deviation 1

Default:20.0%

0.0%~PA-20

PA-20

PID parameter

switchover deviation 2

Default:20.0%

PA-19~100.0%

In some applications, a set of PID parameters cannot meet the

requirements of the entire running process, and different PID parameters

need to be used in different situations. This set of function codes is used for

switching between two sets of PID parameters. The setting of the regulator

parameters PA-15~PA-17 is similar to the parameters PA-05~PA-07.

The two sets of PID parameters can be switched by the multi-function X

terminal, or can be automatically switched according to the deviation of the

PID.

When the multi-function X terminal is selected for switching, the multi-

function terminal function selection should be set to 43 (PID parameter

switching terminal). When the terminal is invalid, select parameter group 1

(PA-05~PA-07). When the terminal is valid, select the parameter group. 2

(PA-15~PA-17).

When automatic switching is selected, the absolute value of the deviation

between the given and feedback is less than the PID parameter switching

deviation 1 PA-19, and the PID parameter selects parameter group 1. When

the absolute value of the deviation between the given and the feedback is

greater than the PID switching deviation 2 PA-20, the PID parameter

selection selects parameter group 2. When the deviation between the given

and feedback is between the switching deviation 1 and the switching

deviation 2, the PID parameter is the linear interpolation value of the two sets

of PID parameters, as shown in Figure 6-29.

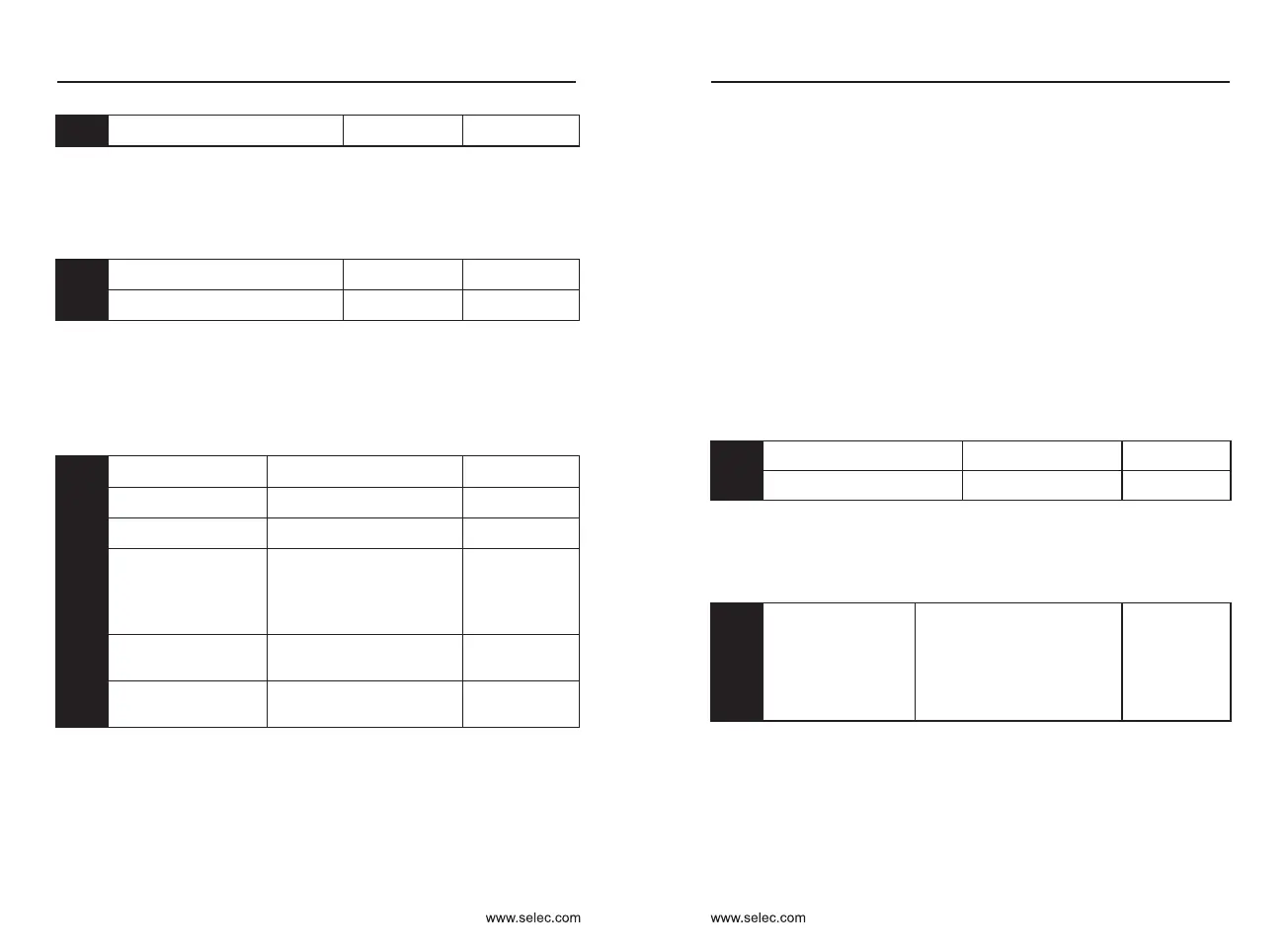

PA-21

PID initial value

Default:0.0%

0.0%~100.0%

PA-22

PID initial value hold time Default:0.0s

0.00~650.00s

When the inverter starts, the PID output is fixed to the PID initial value PA-

21. After the PID initial value hold time PA-22, the PID starts the closed-loop

adjustment operation. Figure 6-30 shows the function of the PID initial value.

Figure 6-30 Schematic diagram of PID initial value function

PA-25

PID integral attribute

Default:0.0%

Ones place:Integral separation

0: Invalid 1: Valid

Tens place: Whether to stop

integral operation when the

output reaches the limit

0: Continue to integrate

1: Stop integral operation

Whether to stop integral operation when the output reaches the limit: If

"Stop integral operation" is selected, the PID integral operation stops, which

may help to reduce the PID overshoot.

When the integral separation selection is invalid, the integral separation

is invalid regardless of whether the multi-function digital X is valid or not.

If the integral separation is set to be effective, when the multi-function

digital X-integration pause (function 22) is valid, the integral PID integration

of the PID stops the calculation, and at this time, the PID only proportional

and differential action is effective.

Chapter 6 Chapter 6

Loading...

Loading...