User Manual

Chapter 3

MC

R/L1

S/L2

T/L3

R

S

T

X1

X2

X3

X4

X5

X6

COM

Input terminal 1

+10V

AI1

AI2

GND

PE

Frequency given

0-10V

0-20mA Input

0-10V Input

J4 jumper

Frequency setting

power supply

Multi-function

analog inout

W

V

U

PE

QF

(+)/B1

B2

(-)

Braking unit

BR

Analog output

0-10V/0-20mA

RY1

ROA

ROB

ROC

Relay output

RY2

M

Breaker pull-in,

current less than 30A

0-10V

AI2

0-20mA

J5 jumper

0-10V

AO

0-20mA

+24V

Y1

Y2

BR

External keyboard port

J13

FWD

REV

External fault

Multi-pase reference

velocity 1

Default:Running

frequency

Default:

running

indication

Default:

Direction

indication

(Default: Fault output)

Potentio-

meter

3-5K

Common terminal

AO

GND

485+

485-

GND

RS485

communication

Braking resistor

Input terminal 2

Input terminal 3

Input terminal 4

Input terminal 5

Input terminal 6

Multi-pase reference

velocity 2

Multi-pase reference

velocity 3

Default

settings

3 phase power supply

Single phase 220V inverter

input connect with L N

415V±15%, 50/60Hz

PE

User Manual

Chapter 3

11

10

3-3-2 Connection of inverter output terminals U, V, W

Ÿ The inverter output terminals are connected to the 3-phase motor in the

correct phase sequence. If the motor rotates in the wrong direction, the

wiring of any two phases of U, V, and W can be exchanged.

Ÿ The output side of the inverter cannot be connected to the capacitor and

the surge absorber.

Ÿ When the wiring between the inverter and the motor exceeds 50 meters,

the distributed capacitance between the lines will generate a large

leakage current, which may cause the inverter to over-current trip. At the

same time, in order to avoid damage to the motor insulation, the output

reactor must be compensated. .

Ÿ If the installation location of the inverter is quite sensitive to interference,

please install an output noise filter to reduce the carrier frequency of the

inverter and reduce interference.

3-3-3 Braking resistor and brake unit connection

Ÿ When the load inertia is large and it is necessary to stop frequently or stop

for a short time, when the braking capacity of the inverter is insufficient or

to increase the braking torque, etc., the braking resistor or the braking

unit may be selected as needed.

Ÿ When the inverter has no built-in braking unit, the main circuit (+) and (-)

terminals are connected to the external braking unit.

Ÿ Do not connect the main circuit (+) and (-) terminals to the braking

resistor.

Ÿ The main circuit B1, B2 terminal is connected to the braking resistor

(there is B1, B2 terminal indicates that the inverter has built-in braking

unit).

3-3-4 Inverter Grounding Terminal PE

Ÿ For safety and noise reduction, the ground terminal PE of the inverter

must be well grounded.

Ÿ Use the specified standard grounding wire and be as short and thick as

possible (grounding impedance 10Ω or less).

Ÿ The grounding wire of the inverter must not be grounded together with

large current loads such as electric welders and high-power motors, but

must be grounded separately.

Ÿ The power supply line generally adopts 5 core wires, of which 3 are fire

wires, 1 neutral wire, and 1 ground wire. It is strictly forbidden to use the

neutral wire as ground wire.

Ÿ When multiple inverters are installed together, all inverters must be

directly connected to the common ground.

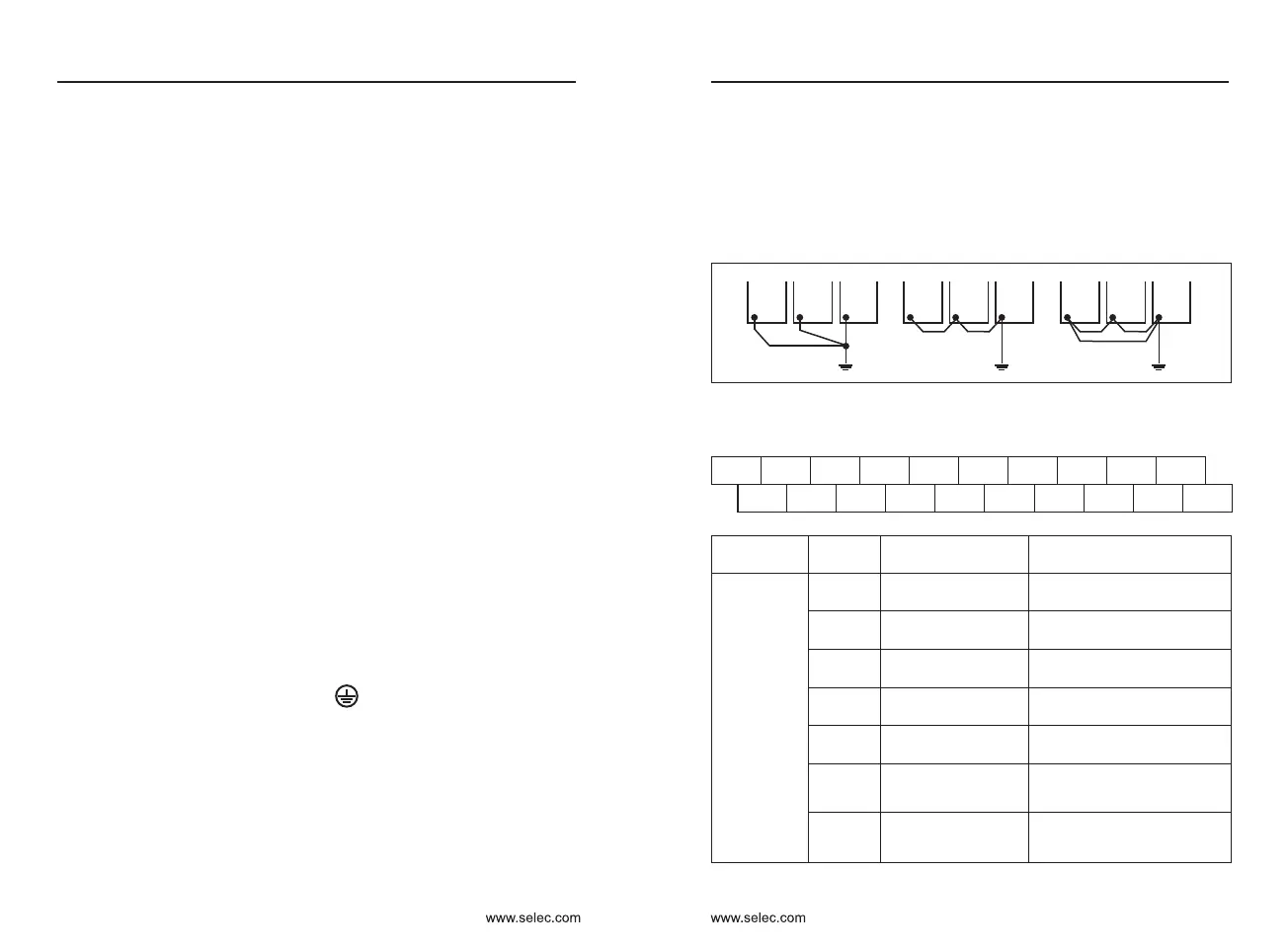

(a) correct (b) not recommend (c) error

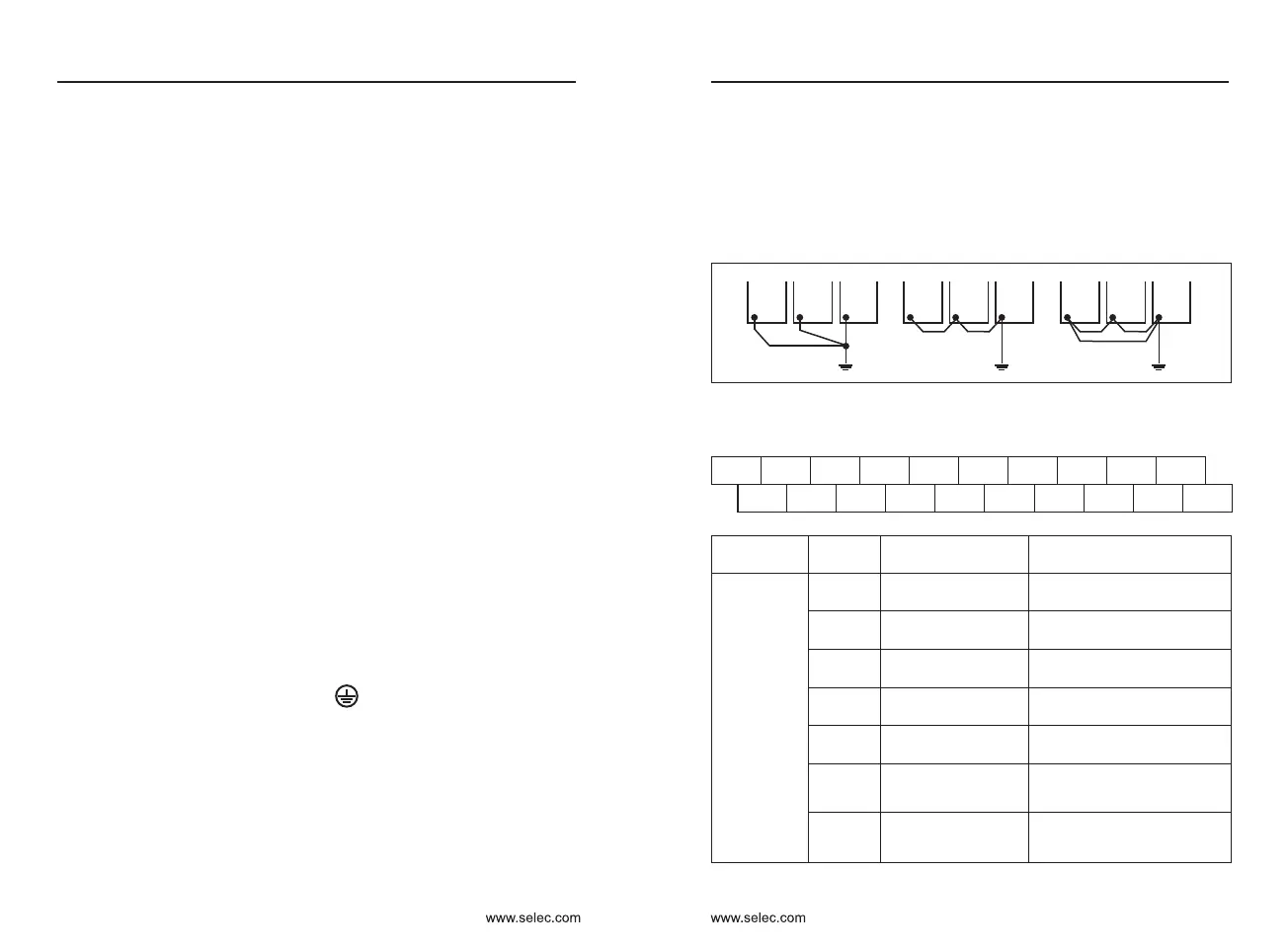

3-4 Control circuit terminal description

Terminal description &

default setting

Classification

Mark

Terminal name

Multi-functional

input

X1

X2

X3

X4

X6

COM

Multi-functional input

terminal 1

Default setting : Forward

Multi-functional input

terminal 2

Default setting : Reverse

Multi-functional input

terminal 3

Default setting : No function

Multi-functional input

terminal 4

Default setting : No function

Multi-functional input

terminal 6

Default setting : No function

can be used as a high

speed pulse input

Public terminal

Multi-functional input common

+24V power supply

reference groung

CN1

Needle base

COM

X5

RS485

485- 485+

8 7 6 543 2 1

6 543

Please refer to the following illustration:

+24V

Y1 Y2

X1 X2

X3

X4 AO

485- 485+

ROA ROB ROC COM

X5

X6

GND

AI1 AI2

+10V

X5

Multi-functional input

terminal 5

Default setting : No function

Loading...

Loading...