ENGLISH

Pag. 33

7. Maintenance

The periodical check-ups and maintenance of the detectors, in the explosion-proof version,

must be carried out by expert personnel according to the criteria of the EN 60079-17 stan-

dard.

7.1 Preventive maintenance routines

Within the European Union countries, bump testing and calibration procedures of gas de-

tectors are required by strict regulations and detailed in the IEC EN 60079-29-2.

This standard gives guidance on the selection, installation, use and maintenance of gas de-

tectors intended for use in industrial and commercial applications therefore the User have

to read the procedure described in IEC EN 60079-29-2 for reference.

The standard requires calibration and bump testing as well as recording of the performed

checks and it denes that all gas detectors should undergo periodical operational testing

according to the manufacturer’s specications. Test results should be recorded into a sui-

table book to be shown to the Local Jurisdiction Authority in case of inspection, according

the IEC EN 60079-17.

7.2 Corrective maintenance routines

For any anomaly found during the functional test, please check the tests performance as

described in paragraph 6.

If during the preventive maintenance routine, the detector does not react to the gas it has

been calibrated for, please return the instrument to your supplier that on his turn will return

it to the manufacturer for repair. It is possible to adjust the calibration parameters by em-

ploying the calibration keypad available on request.

For further information, refer to the calibration kit manual MT894.

7.3 Note on IP grade

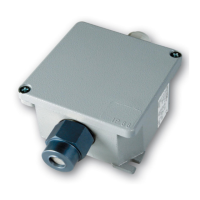

Please note that the IP rating indicated on the instrument label (in case of use of the STGD/

AD2 or STGD/AD3 accessory) does not imply that the equipment will detect gas during and

after exposure to those conditions of dusta and water intrusion.

If exposed to the conditions representative of the IP rating, the equipment should be checked

and recalibrated with a higher frequency and in case of damage of the IP protection cap, it

must be replaced.

The goretex lter of the IP protection cap, should by no means be touched by bare hands as

this may alter the protection and the response in gas.

7.4 Sensor head substitution

If necessary, the sensor head can be substituted. First of all, the user must request to Sensi-

tron and Sensitron will give a proper kit and instructions.

WARNING!

Loading...

Loading...