Doc No. 006-0211-00 Rev AK Page 24 of 33

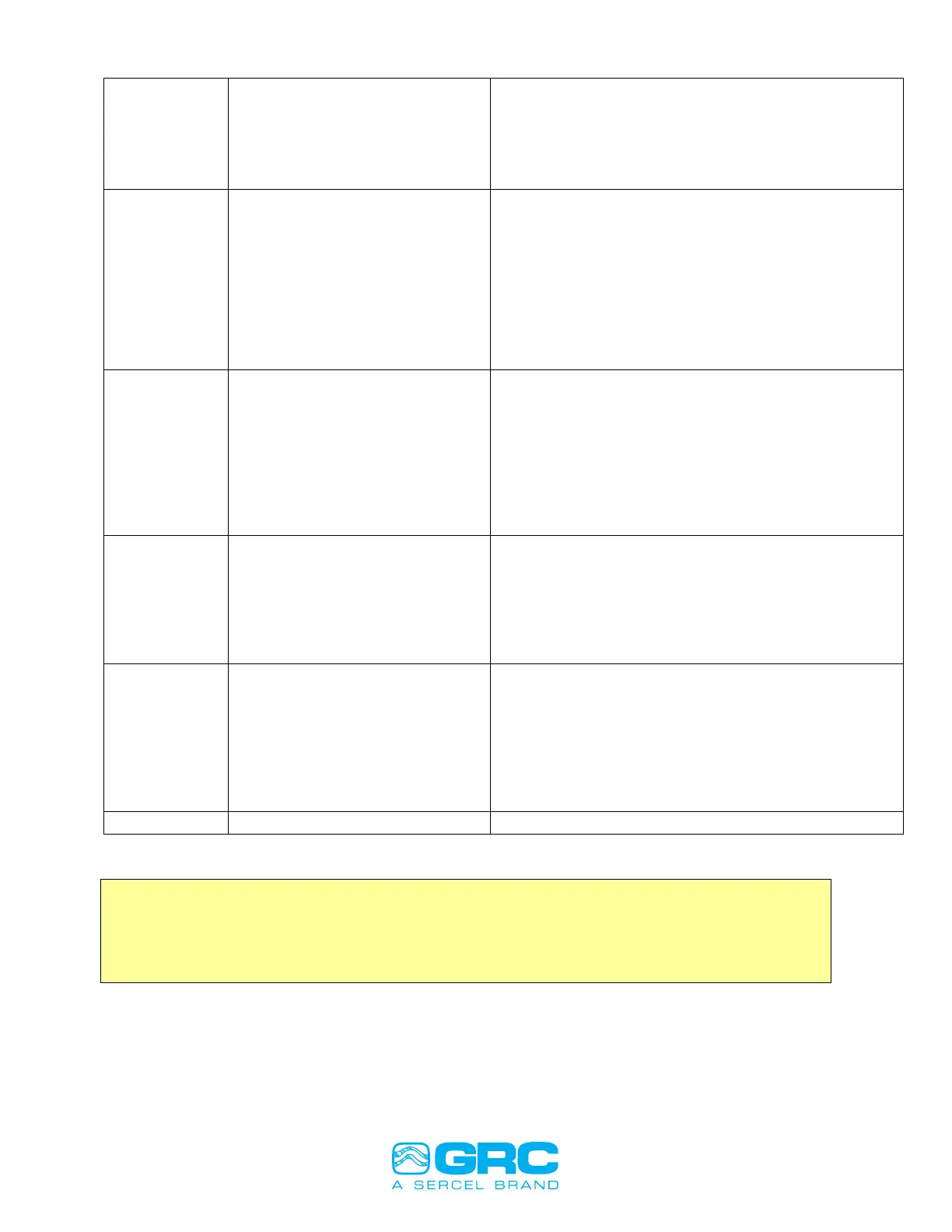

- Check Setting of High amp (25mA normally for

SPS-1500 and 22-26mA normally for SPS-1501)

Verify Downhole readings (Phase to Phase, Phase-

Ground (Reverse Polarity Megger))

Replace the SPS-1500/SPS-1501

Analyzing –

(SPS is

adjusting

output voltage

to analyze

gauge signal)

Normal Operation message

unless message is continuous

or repeating over 5 minutes.

If message is continuous or repeats over 5 minutes:

o Check all wire connections

o Check Phase to Phase and Phase-Ground

connection (Reverse Polarity Megger) (Applies to

SPS-1500 only)

o Check Signal fuse

o Adjust Set voltage (Approx. 60+/- for 1500 and

Approx. 40+/- for the SPS-1501). This can be

done using “DataWorks” software.

No Tool – (No

Tool indicates

there is no

gauge current)

Blown SPS Fuse

Blown Surge Protector

Fuse/MOV

Bad SPS to Gauge Signal wire

connection

No-Tool Current setting

incorrect in SPS

Read the DC current drawn by the gauge with an

ammeter in series and DC mode. DC current is

normally 15-30mA.

Check all fuses and surface connections.

If connections and equipment okay error may

indicate possible downhole connection is open.

Using “DataWorks”, verify “No Tool Amp” value is set

to 5.3mA (default value).

Line Noisy –

(SPS is unable

to measure

current

modulation

from gauge)

Motor WYE phase imbalance

voltage is high

Check all fuses and surface connections.

If connections and equipment okay error may

indicate possible downhole problem.

Check line voltage at wye point on surge protector for

motor noise injection.

No Signal –

(SPS

measures

gauge current

but no

modulation

current)

Possible SPS/gauge firmware

corruption

Possible SPS/gauge

component failure

No-Tool Current setting

incorrect in SPS

Use DC Ammeter to measure DC current from SPS

to gauge. Gauge current is normally modulated from

approximately 15mA to 25mA. If not modulated,

check SPS and connections.

Normal Operation, no errors

SPS is communicating with the gauge

Table 2: Surface Interface Troubleshooting

Note: Many communication problems with the Surface Interface can be solved with

proper grounding techniques. A good ground must be established from the

production tubing at wellhead back to the ground point at the surface package for

proper operation.

Loading...

Loading...