29

9.0 Setup Guidelines

Setting up a racecar with fully independent suspension, like your

Serpent 950, is necessary to make the car perform well. We have

developed these straightforward procedures to help you set up your

car properly and easily. Always follow these procedures step-by-

step, in the order presented, and always make sure that you make

equal adjustments on both left and right sides of the car.

The set-up described here is a good starting point, but you may

adjust the settings to better suit different track conditions. Make

only small adjustments at a time, and see if you find any improve-

ment in handling with each adjustment. We advise you to keep

track of your set-up changes, and record which set-ups work best

at different racetracks under various conditions. After rebuilding the

chassis, or in case you are lost with your set-up, always return to

the set-up described here.

1 Shock absorbers

Shock absorber dampening influences the responsiveness of the

chassis during cornering (chassis roll), and helps to maintain proper

contact between the tire and the road surface during vertical move-

ment. Setting the right dampening is therefore always a compro-

mise and requires a lot of "hands on" experience.

No dampening means that the spring rate determines how long it

takes for the spring to compress and the suspension to reach a sta-

ble position. Dampening only comes into play when the suspension

is moving (either vertical chassis movement or because of chassis

roll), and loses its effect when the suspension has reached a stable

position. When the spring is compressed or decompressed, the

shock absorber oil resists this movement. How much it resists

depends on the thickness of the oil and how much the flow is

restricted (the number of holes in the shock piston) and of the

velocity of the piston.

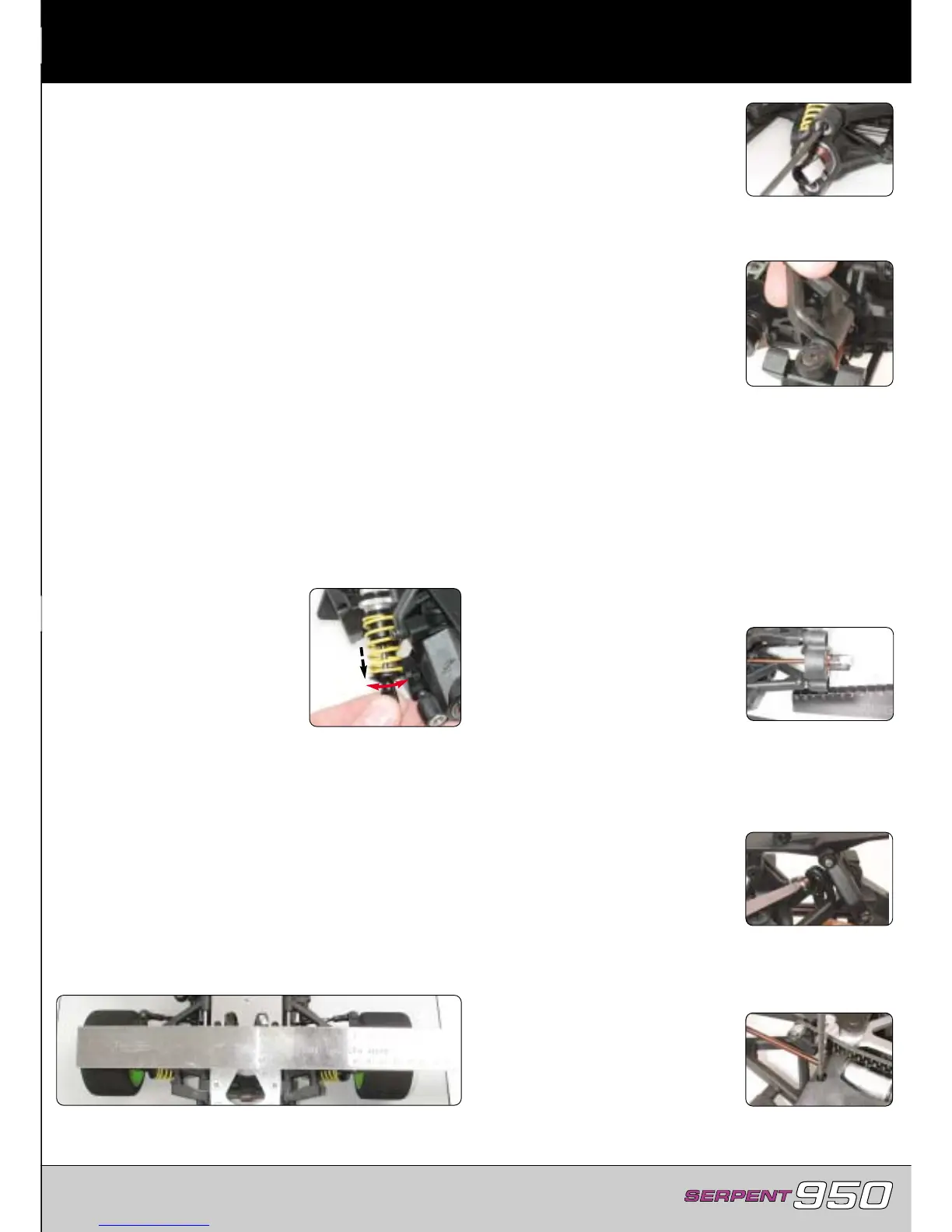

How to measure and adjust

The Serpent shock absorbers are

adjustable from the outside. Pull out the

pistonrod and turn it slightly until it

locks in the shock-cylinder. By turning

the pistonrod clockwise until the end

you reach the hardest position (1 hole).

Turning it from here anti-clockwise

means opening more holes. By feeling

the "clicks" you can determine the num-

ber of holes in the piston.

1.1 Front shock absorber setting

Adjust the front shocks to 2 holes (complete turn clockwise, then 1

click back)

1.2 Rear shock absorber setting

Adjust the rear shocks to 2 holes (complete turn clockwise, then 1

clicks back)

2 Track-width

Track-width affects the car's handling and steering response.

Increasing front track-width will result in more understeer, while

decreasing it will result in less understeer and faster steering

response.

Increasing rear track-width creates more rear traction, as long as

the car has a solid rear axle as it is in the 950. It may also help in

case of traction rolling.

2.1 Front track-width - Setting

Front track-width is measured on the out-

side of the wheels. It is important that

the front track-width is adjusted

symmetrically, meaning that the right and

left wheels must be the same distance

from the center-line of the chassis.

Set the front track-width to 254mm. Turn both pivot balls IN equally

to reduce track-width, turn them both OUT equally to increase

track-width.

2.2 Rear track-width - Setting

Rear track-width is measured also on the

outside of the wheels. As in the front it is

important that the rear track-width is

adjusted symmetrically, meaning that the

right and left wheels must be the same

distance from the center-line of the chas-

sis.

Set the rear track-width to 262mm. This is achieved by first remov-

ing both rear upper wishbone mounting points from the rear

upright. Unscrew both sides, together with the two lower pivot

balls, out to make wider and in to make narrower.

3 Downstops

Downstops limit how far the suspension arms travel downward

(which determines how far upwards the chassis travels). The

amount of downward suspension travel affects the car's handling,

and the effect may change with the type of track and/or amount of

grip available. In general, more suspension travel (less downstop)

makes the car more responsive but less stable. It is also better on a

bumpy track.

It is very important to adjust the downstops such that left and right

sides are equal.

How to measure

You check the downstops with the chassis

elevated above a reference surface. A

special, flat reference board is available

from HUDY (#108200 Flat Set-up Board).

We also advise you to use the downstop

measuring set from HUDY.

Using the measuring gauge, measure the distance from the refer-

ence surface to the bottoms of the rear uprights / front steering

blocks. Positive numbers indicate the distance (in mm) ABOVE the

level of the elevating blocks (or, above the bottom of the chassis).

Negative numbers indicate the distance (in mm) BELOW the level of

the elevating blocks (or, below the bottom of the chassis).

Perform these initial steps

A Remove the wheels from the car.

B Front anti-roll bar: Remove screw from

the right front anti-roll bar mount to dis-

connect it.

C Rear anti-roll bar: Disconnect one ball-

joint from rear anti-roll bar.

Remark: it is not necessary to remove the shocks, however you

must be sure that they are long enough not to limit the suspension.

Be sure the suspension is reaching the downstop limits, before the

shocks do.

3.1 Downstops front

Adjust the front downstop screws so that

the bottoms of the steering blocks are at

0mm on the gauge. (Actual measurement

= 0 mm above level of elevating blocks,

or level with the bottom of the chassis).

C

Loading...

Loading...