Analyzer Start-Up Procedure DF-150E 13

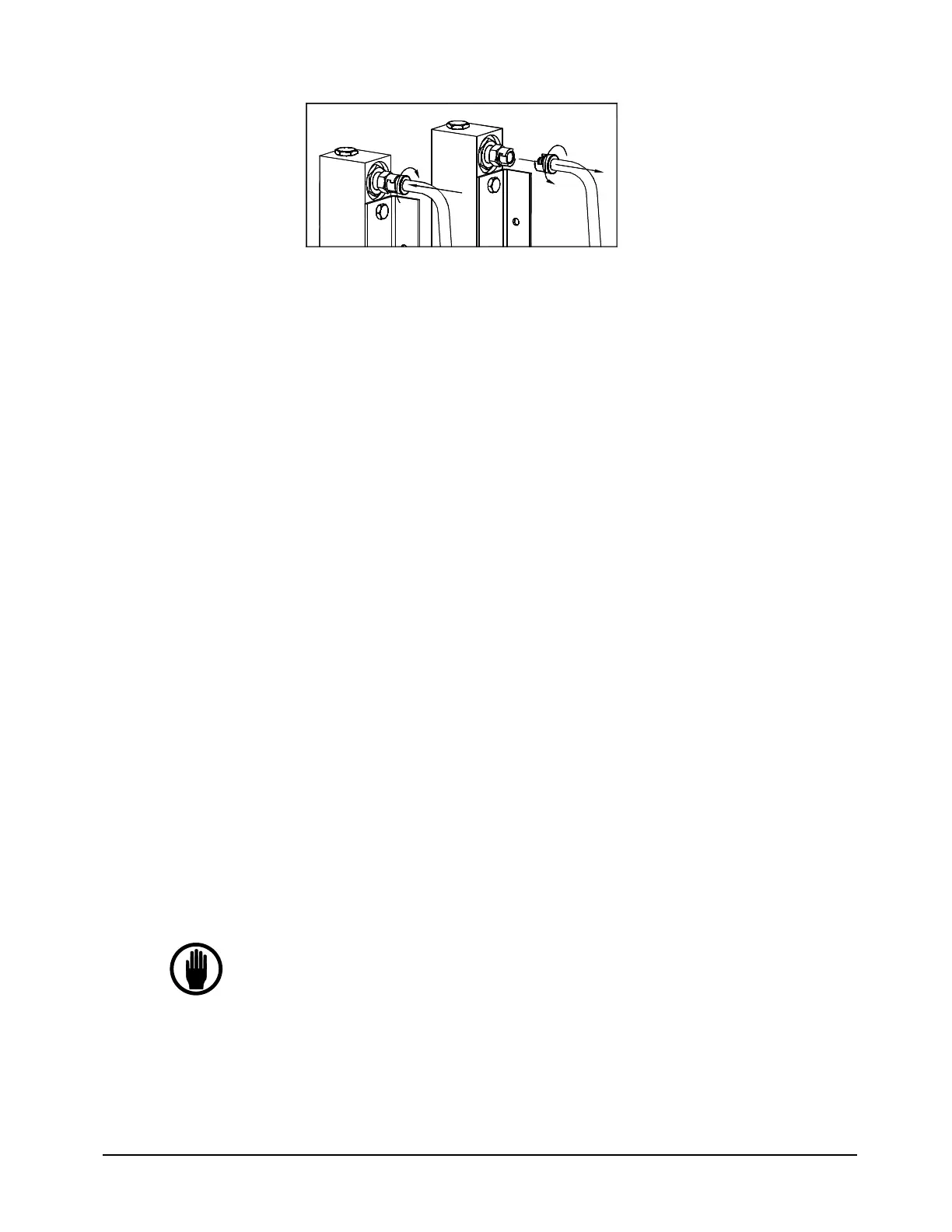

PUSH

ROTATE

PULL

ROTATE

Figure 3: Quick Disconnect

5.1.2 Add Electrolyte

1. Un-screw the lid from the sensor.

2. Add the entire contents of one bottle of Hummingbird Brand E-Lectrolyte

Blue to the sensor.

3. Replace the lid securely.

5.1.3 Re-install the Sensor

1. Attach the quick disconnect at the top of the flowmeter. (Skip this step if

the analyzer is equipped with the stainless steel outlet tubing option.)

2. Carefully slide the sensor into the analyzer.

3. Tighten the thumbscrews.

4. Re-connect the electrical cable to the sensor.

5. Replace the bulkhead nut on the inlet gas connection on the rear of the

analyzer. NOTE: After seating the nut finger tight, use a wrench to turn it

only an additional 10 degrees. Do not over tighten the bulkhead nut.

6. If the analyzer is equipped with the stainless steel outlet tubing option,

replace the nut on the outlet bulkhead fitting.

7. Allow the sensor to sit for 60 minutes before starting gas flow.

5.2 Making Sample Gas Connections

NOTE

For gas pressures between 1.0 and 5.0 psig use a high quality flow

control valve between the gas source and the analyzer to set the

flow rate.

You may have an optional Flow Control Valve mounted on the

sensor bracket and accessible behind the door (see “Flow Control

Valve” on page 24).

For gas pressures above 5 psig use a high quality pressure

Loading...

Loading...