14 DF-150E Analyzer Start-Up Procedure

regulator to set the flow rate.

NOTE

For best results, after putting electrolyte in the sensor, allow the

sensor to sit for 60 minutes before starting gas flow.

5.2.1 Gas Connection

1. Connect the gas line to the

1

/8 inch compression fitting marked sample inlet

on the rear of the analyzer.

2. Open the door and slowly adjust the flow rate to 1.0 scfh as indicated on

the flowmeter using the flow control valve or pressure regulator. Do not

control the flow with the valve mounted in the flowmeter on positive

pressure installations.

3. If you are using a gas other than nitrogen, you must set the “indicated”

flow rate as shown in Table 1.

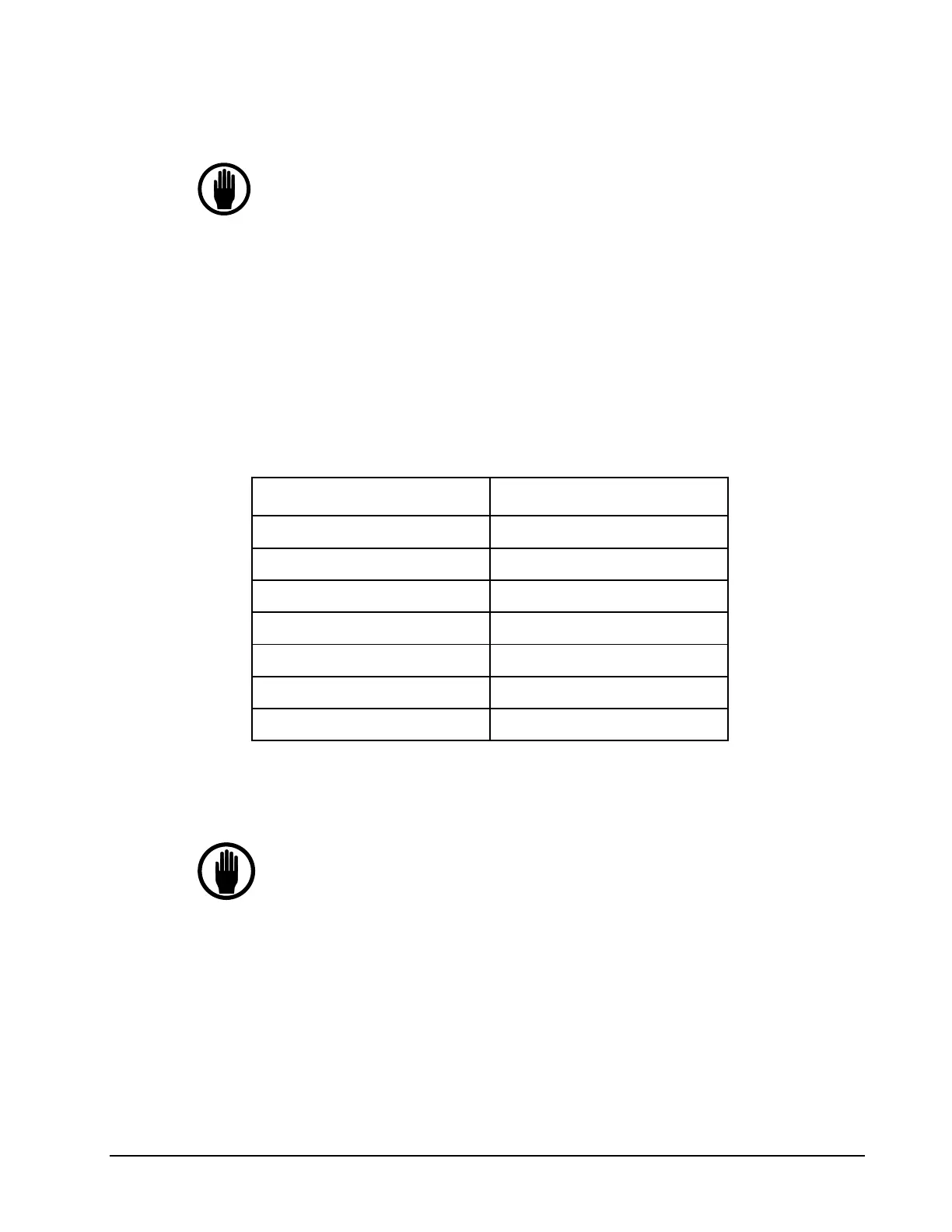

Background Gas Flowmeter Setting (scfh)

Argon 1.2

Ethylene 1.0

Nitrogen or Air 1.0

Carbon Monoxide 1.0

Methane 0.8

Hydrogen 0.3

Helium 0.4

Table 1: Flowmeter Settings versus Background Gas

NOTE

Unless otherwise requested, the analyzer is factory calibrated on

nitrogen. Analyzer readings will be inaccurate if used with a

background gas other than the one for which it is calibrated. If the

analyzer was calibrated on a gas other than nitrogen, the gas will

be noted on the calibration log inside the front door and on a label

below the display.

5.3 Making Output Signal Connections

The following considerations are important when performing this step:

The analog output signal is factory-set to 0 to 10 VDC unless otherwise

specified.

Loading...

Loading...