4.2

Note: the following presumes that background gases, in the typical sample stream, will have

no effect on the sensor readings. If this is not the case, calibration gases should be modified

accordingly.

4.2.1 Gfx transducer low and high calibration

The low calibration gas for Gfx gas sensor modules may be specified between -5vpm and

+5vpm of the measured component. Zero grade nitrogen is recommended.

The high calibration gas can be in the range 6 to 110% of the transducer's FSD. As Gfx sensors

are configured as 'dual range' units, it is recommended that the high calibration gas is selected

at the top end of the range used.

4.2.2 IR transducer low and high calibration

Typically zero grade nitrogen is recommended for low calibration.

It is recommended that the high calibration gas is in the range 80 to 110% of the transducer's

FSD.

4.2.3 Paramagnetic transducer low and high calibration

The low calibration gas for paramagnetic gas sensor modules may be specified between -3%

and +3% oxygen. This is to allow for the situation where the background gas affects the

paramagnetic zero (see Appendix A). Zero grade nitrogen is recommended.

The high calibration gas can be in the range 5 to 100% oxygen. For purity measurements a

high calibration gas with approximately 100% oxygen is recommended, for other paramagnetic

transducers 21% (air) is adequate.

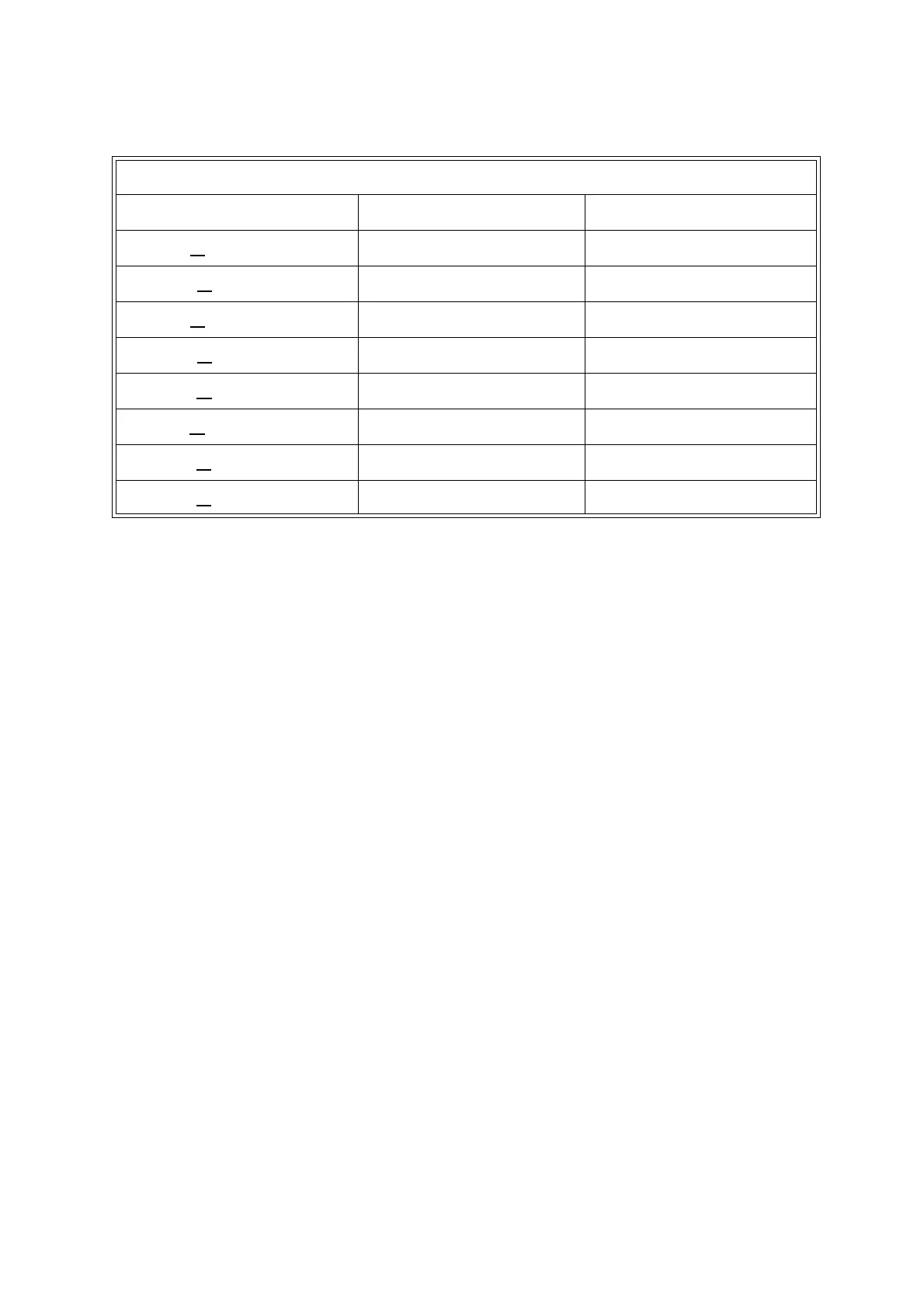

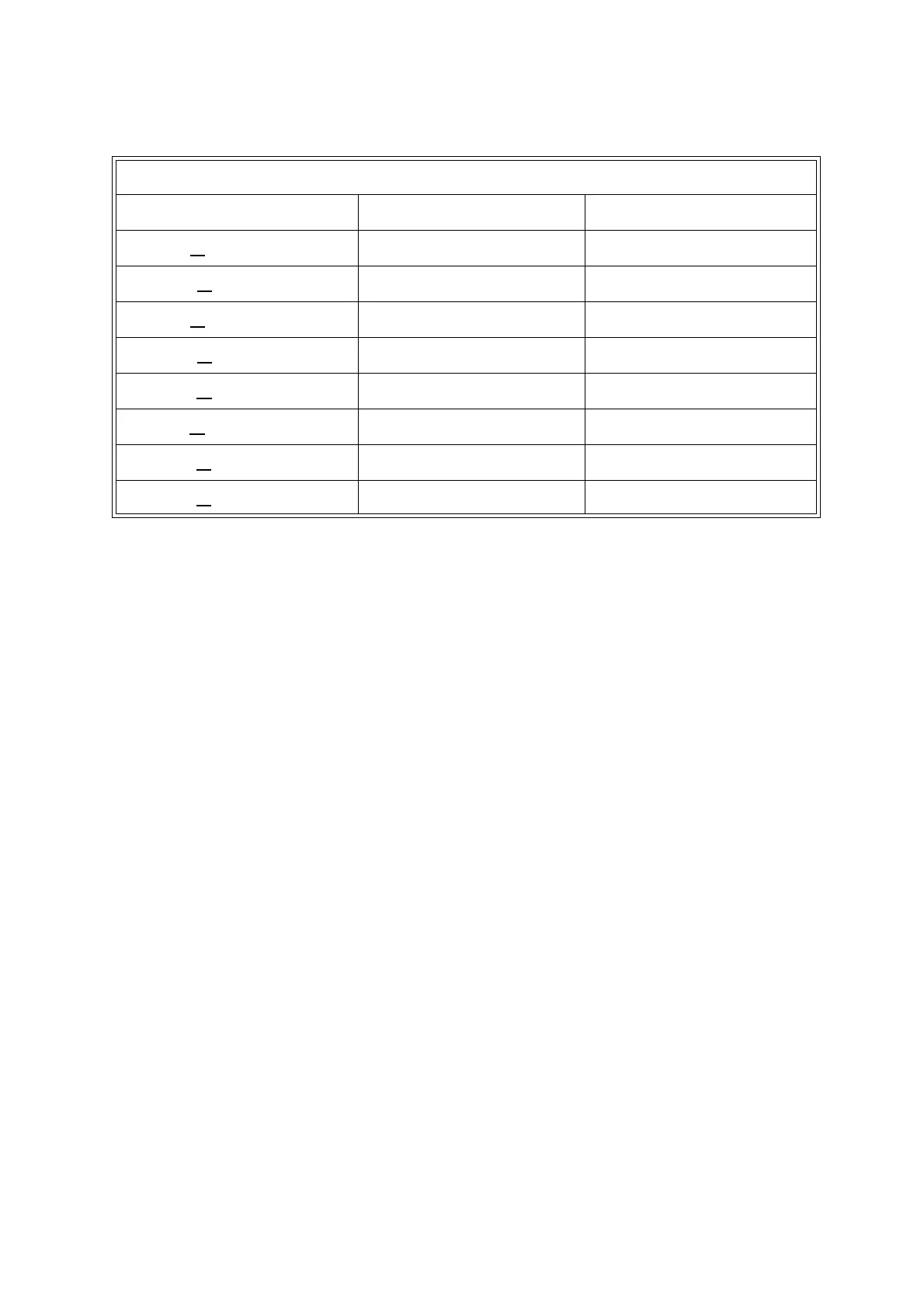

Table 4.1: 4900D calibration gas examples

Gas components measured Calibration gas 1 Calibration gas 2

CO only or

CO+O

2

"zero grade" N

2

*

CO in air gas mix

CO+CO

2

or CO+CO

2

+O

2

"zero grade" N

2

CO+CO

2

in air gas mix

NO only or

NO+O

2

NO in N

2

gas mix Air

NO+CO

2

or NO+CO

2

+O

2

NO in N

2

gas mix CO

2

in air gas mix

SO

2

only or SO

2

+O

2

"zero grade" N

2

*

SO

2

in air gas mix

CO+NO or

CO+NO+O

2

NO in N

2

gas mix CO in air gas mix

CO+SO

2

or CO+SO

2

+O

2

"zero grade" N

2

*

CO, SO

2

in air gas mix

NO+SO

2

or NO+SO

2

+O

2

NO in N

2

gas mix SO

2

in air gas mix

Loading...

Loading...