B.1

APPENDIX B MODBUS PROFILE

The analyser supports Modbus slave communication through the serial data connector (PL6).

This supports an RS232 or RS485 multidrop link to a Modbus master. The implementation of

Modbus is based on the “Modicon Modbus Protocol Reference Guide PI-MBUS-300 Rev. J”

dated June 1996.

The following facilities are provided:

• Access to measurement data

• Access to derived measurement data

• Access to external analogue input data

• Access to measurement status and alarm information

• Access to analyser status information

• Initiation of individual autocalibration groups

• Progress indication of autocalibration

• Ability to stop current autocalibrations

• Diagnostic and error functions

These are described below.

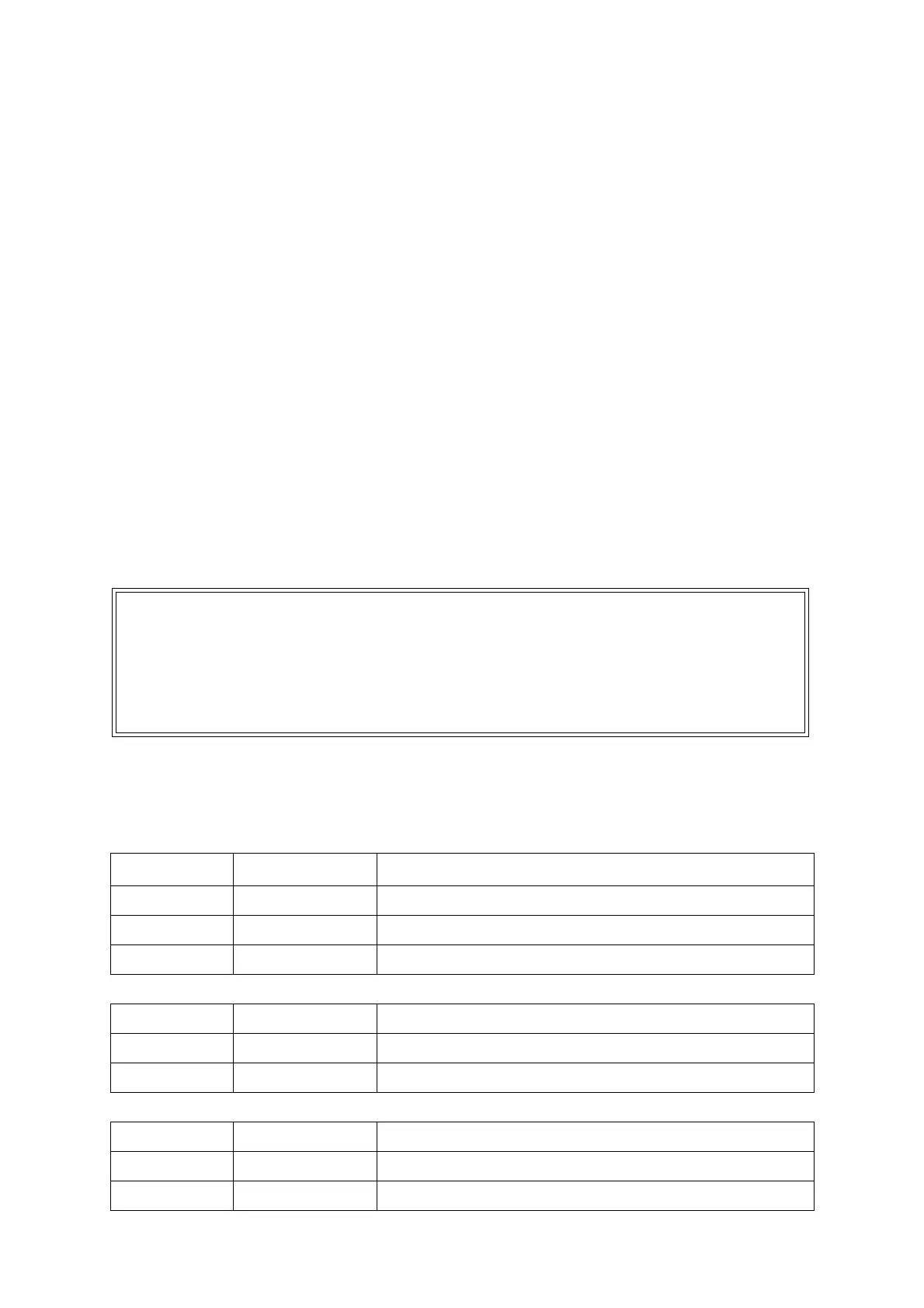

Measurement data

Measurement data from each of the four possible transducer positions is available in a block

of input registers that can be read using Modbus function code 04.

NOTE

Measurement data is in IEEE 754 floating point format. Each value requires 2 registers as

follows:

Register N = High word

Register N + 1 = Low word

Registers Name Comments

30001 – 30002 I1 Measurement Measurement 1 value in IEEE 754 floating point format

30003 – 30005 I1 Name A 6 character string containing the measurement 1 name

30006 – 30007 I1 Units A 3 character string containing the measurement 1 units

30008 – 30009 I2 Measurement Measurement 2 value in IEEE 754 floating point format

30010 – 30012 I2 Name A 6 character string containing the measurement 2 name

30013 – 30014 I2 Units A 3 character string containing the measurement 2 units

30015 – 30016 I3 Measurement Measurement 3 value in IEEE 754 floating point format

30017 – 30019 I3 Name A 6 character string containing the measurement 3 name

30020 – 30021 I3 Units A 3 character string containing the measurement 3 units

Loading...

Loading...