4.5

4.4 Reading flowmeters

The optional flow monitors are provided to control and measure the flow of sample gas through

the analyser. The flow monitor consists of an optional needle valve (4900D only) and a

rotameter type flowmeter. The reading of the flow rate through the flowmeter is obtained by

observing the scale indication at the top of the float.

4.5 Autocalibration overview

The autocalibration facility allows the instrument's calibration to be updated or checked without

user intervention.

When external autocalibration valves or an internal autocalibration manifold are fitted, a

manual calibration adjustment or calibration check will use the autocalibration valves to select

the calibration sample gases as required.

The autocalibration process can be initiated in four ways:

by an internal timer;

by an external contact closure (refer to Section 3.4);

by operator request through the user interface;

or by an external Modbus command.

Autocalibration facilities are offered to either measure or check the following:

• Transducer low calibration ( 'zero' calibration ).

• Transducer low and high calibration ( both 'zero' and 'span' ).

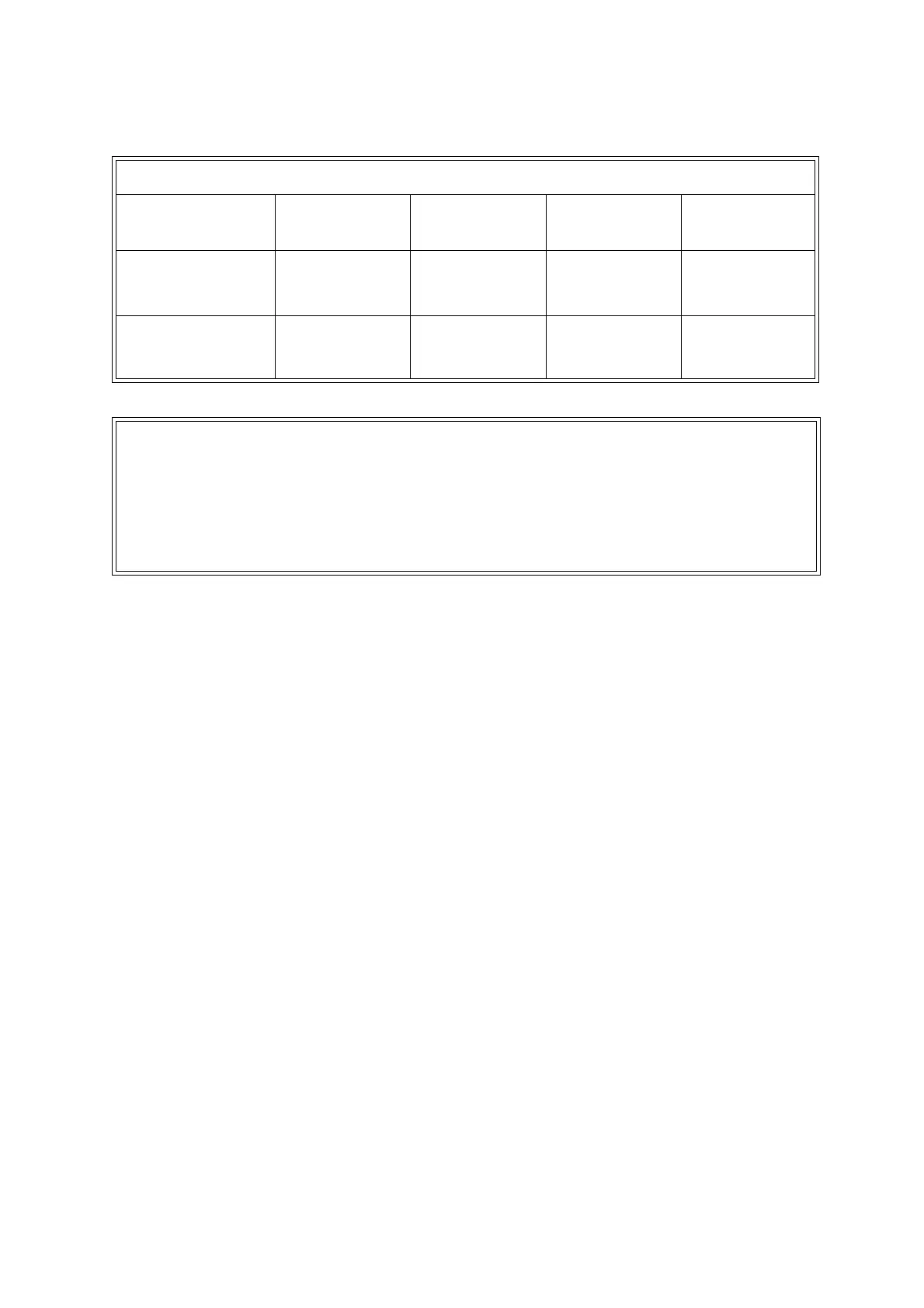

Table 4.4: 4900D sample port type

Gas sensor

module type

Sample inlet Sample outlet Low cal gas High cal gas

Standard 1/8" NPT

female

1/4" NPT

female

N/A N/A

With internal Auto

Calibration

1/8" NPT

female

1/4" NPT

female

1/8" NPT

female

1/8" NPT

female

WARNING

• Verify that connections are leak free at full operating pressure before applying

sample or calibration gases. These gases may be flammable, toxic or

asphyxiant.

• Consideration should be given to the flammable, toxic and asphyxiant nature

of the sample gas when selecting a vent location.

Loading...

Loading...