B.4

Starting/stopping autocalibration

Using the following block of coils, an autocalibration on a specific calibration group may be

started, or all calibrations may be stopped.

The action will be requested when a coil state is changed from a 0 to a 1. This request is treated

in the same way and subject to the same rules as a request initiated from the keypad. The

Modbus master is responsible for subsequently returning the state to 0.

Coil states may be written using function codes 05 or 15. If desired, their current state may be

read back with function code 01.

Diagnostic functions

Modbus function code 08 provides a diagnostic capability for checking communication between

the master and the analyser. Following the function code is a 2-byte sub function code that

specifies the test to be performed, followed by data.

This implementation only supports sub function code 00 which causes the data passed in the

query field to be looped back.

Exception codes

If a communications error (e.g. framing error, checksum error) is detected during the receipt of

a Modbus message, that message is ignored and no response is generated.

All correctly received Modbus messages are checked for a valid function code and data

address. If a problem is detected the following exception responses are returned.

Where a request to write a coil state is received, the data field is validated against the Modbus

standard. Invalid data is rejected and results in an exception response.

The exception codes are as follows:

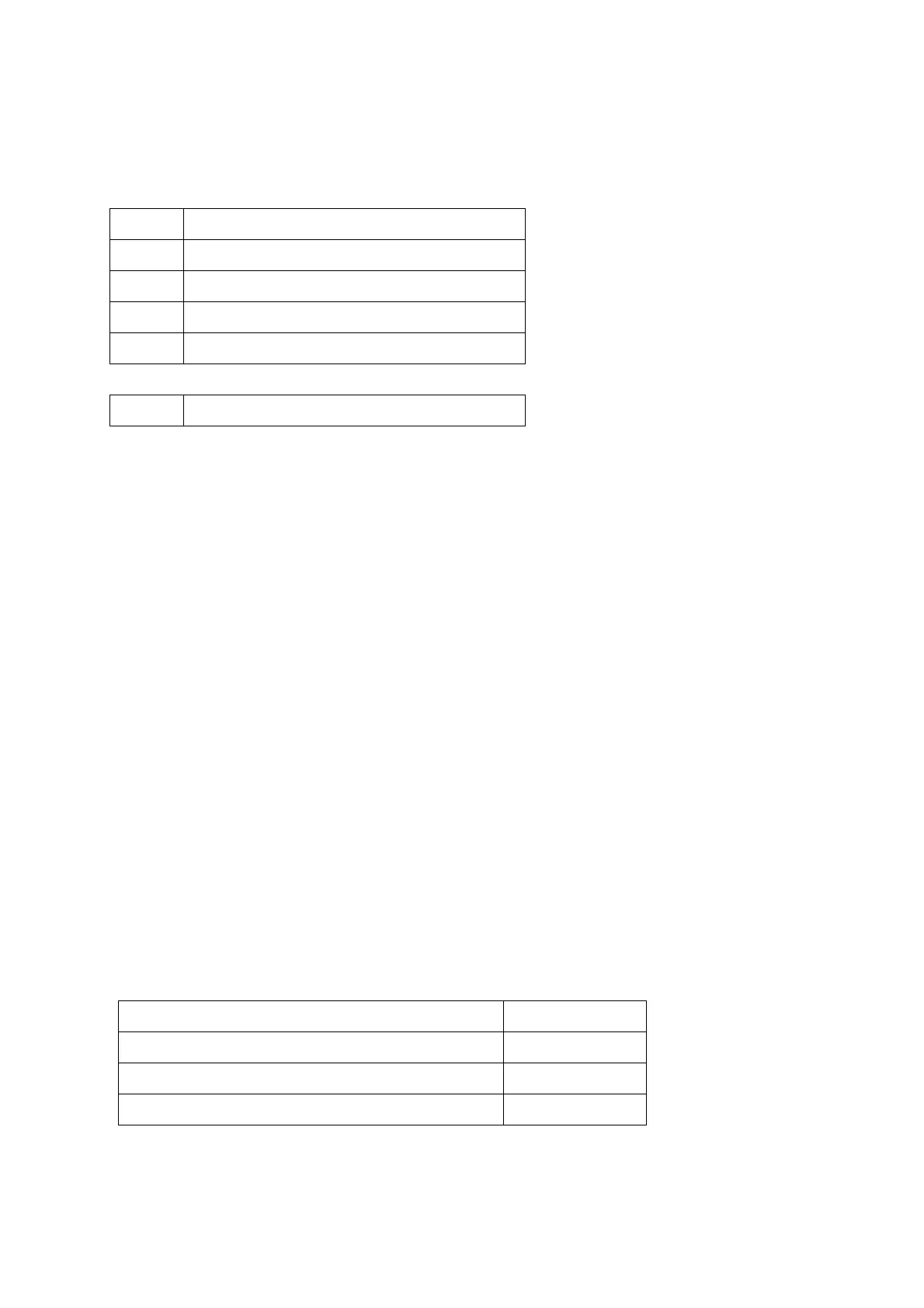

Coil Description

00001 Start Calibration Group 1

00002 Start Calibration Group 2

00003 Start Calibration Group 3

00004 Start Calibration Group 4

00009 Stop all autocalibrations (however initiated)

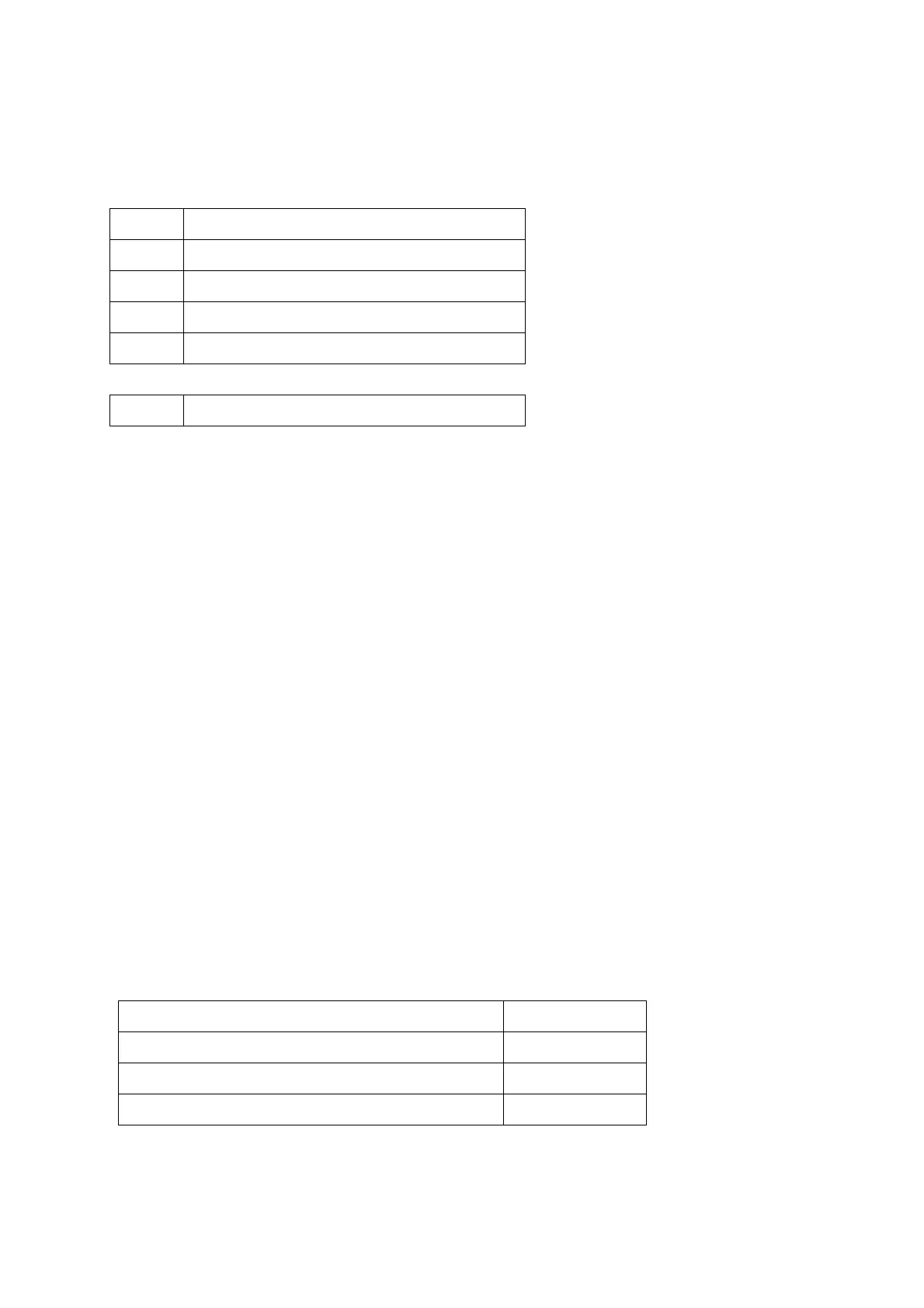

Condition Exception Code

Requested function code is not supported 01

Register or coil address outside of supported range 02

Invalid data 03

Loading...

Loading...