Introduction

Manual – ECC-DFC field bus controller

3. Introduction

3.1. The concept

The ECC-DFC fieldbus controller that is used for conveyor belt control is a series

of individual ECC-DFC modules that are connected to each other via Ethernet

cabling in order to provide a complete solution for the function of motor rollers in

conveyor systems. Each module can operate up to 2 ECR motor rollers and 2

photo sensors in order to control up to 2 conveyor belt zones.

Each ECC-DFC module also has practical interfaces to the upstream and down-

stream Ethernet network cabling.

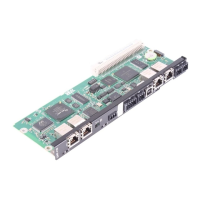

Figure 1 ECC-DFC fieldbus controller with 3 MODULES

The software of ECC-DFC modules can be easily configured in order to operate

several zones of linear conveyors with the ECShell engineering software. The

default settings of each ECC-DFC module can also be modified using ECShell in

order to adapt the function to specific applications.

3.1.1. System components

The typical components that are needed for a system with ECC-DFC fieldbus

control are listed in the following:

Modules of the ECC-DFC fieldbus controller

Motor rollers (1 – 2 per module)

Photo sensors (1 – 2 per module)

DC 24 V current supplies

3.2. Module properties

Each ECC-DFC module has the following properties:

Installed Ethernet switch

Modular M8 sockets for the photo sensors

Modular M8 connectors for the motor rollers

DC 24 V power connection with separate current supplies for logic and motors

Context-sensitive, multi-colored LED displays

Thermal protection and overcurrent protection for motor rollers

Automatic light/dark detection for the photo sensor inputs

Automatic PNP/NPN detection for the photo sensors

Proportional/integral (PI) motor roller speed control as an option

Four motor roller braking methods

Adjustable acceleration and deceleration time

Degree of protection IP54

Loading...

Loading...