MX-5001N DEVELOPING SECTION K – 2

2. Operational descriptions

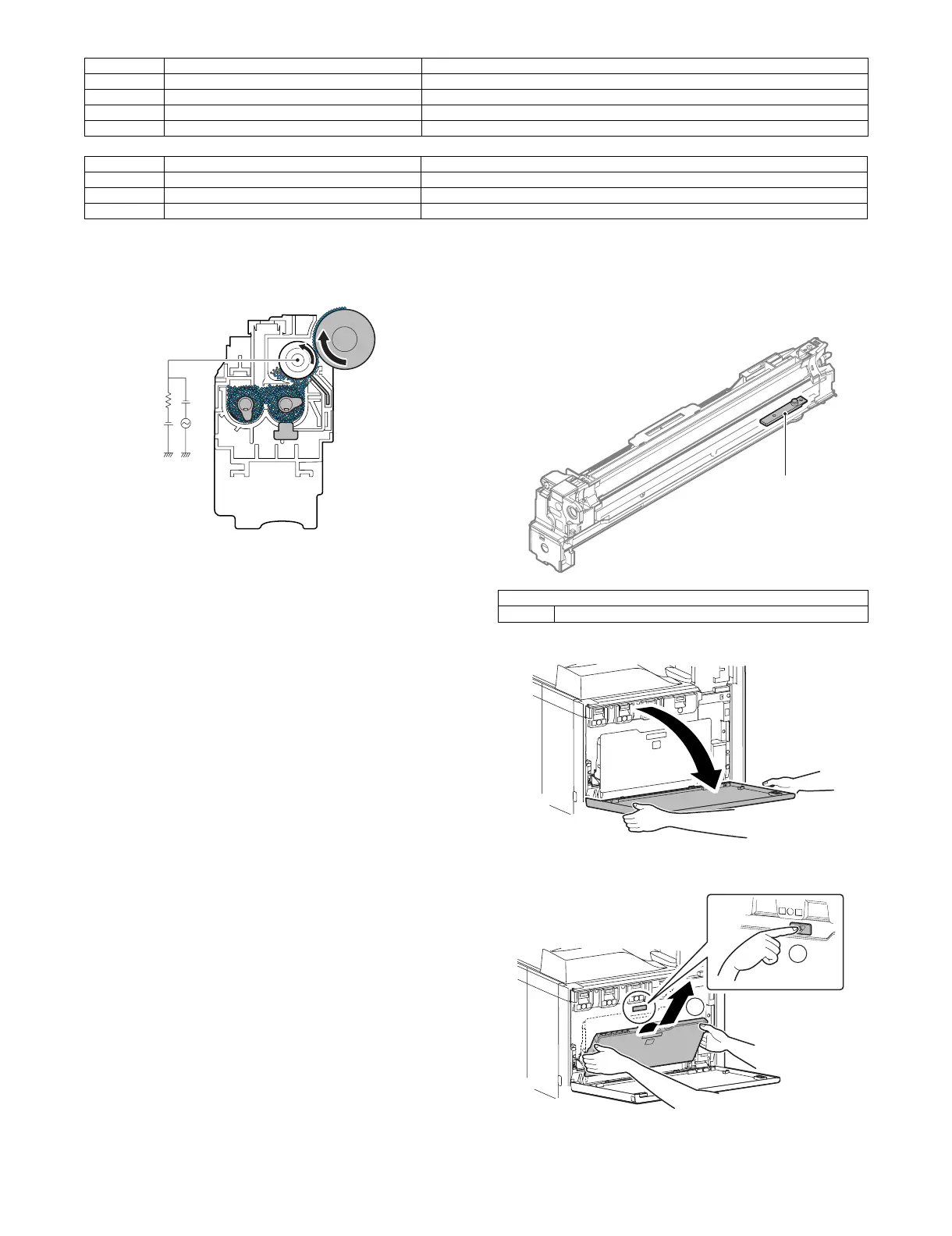

This converts the electrostatic latent images on the OPC drum gen-

erated by the laser (writing) unit into visible images with toner.

Toner and carrier in the developing unit are stirred and transported

by the mixing roller.

By mixing and transporting, toner and carrier are negatively

charged due to mechanical friction.

The developing bias voltage (AC component and negative DC

component) is applied to the developing roller.

Negatively charged toner is attracted to the exposed section on the

OPC drum where the negative potential falls due to the developing

bias.

If the OPC drum is not exposed, the negative potential is higher

than the developing bias voltage, and toner is not attracted.

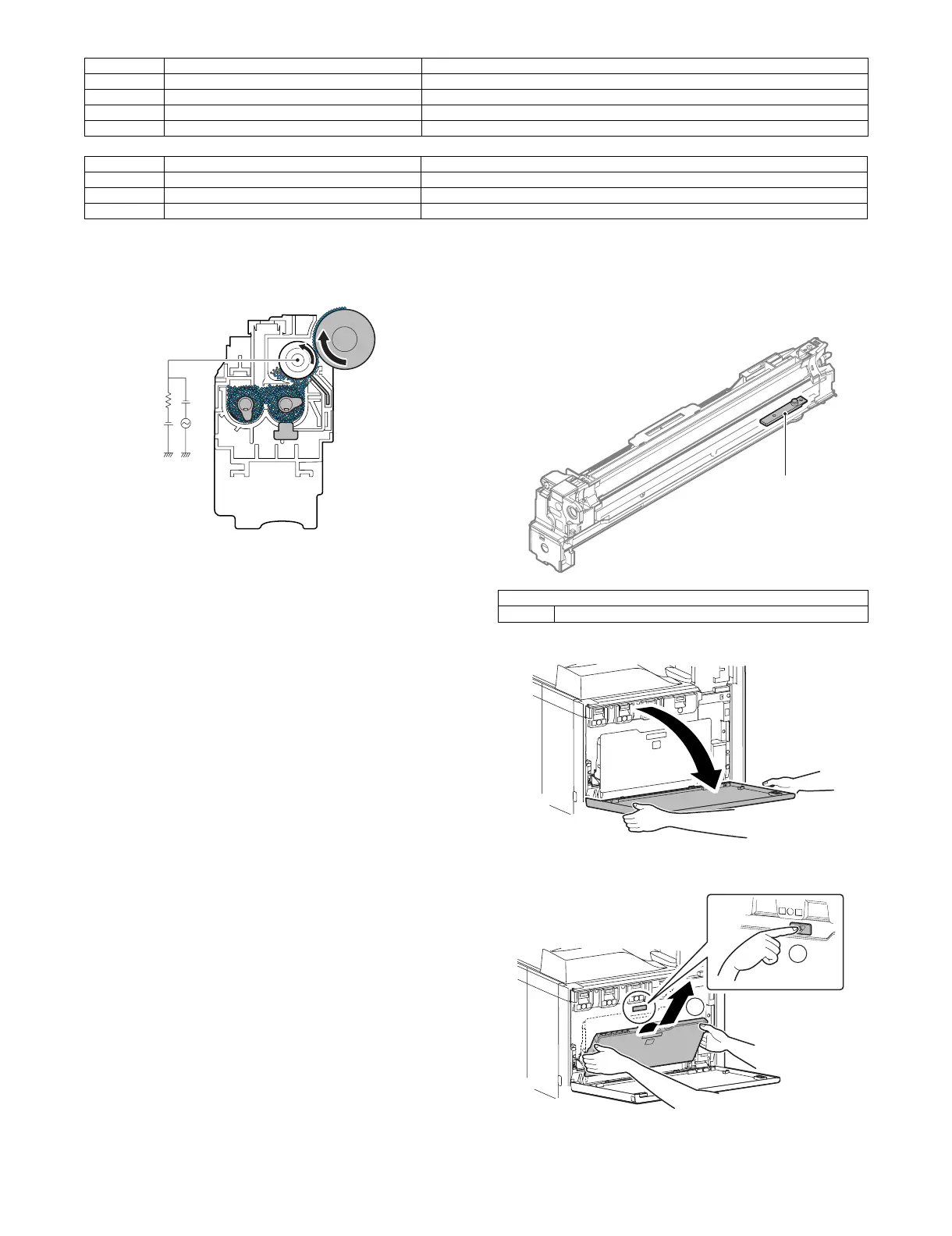

3. Disassembly and assembly

Be careful not to attach fingerprints or oily dirt on the DV roller sur-

face.

A. Development unit

1) Open the front cover.

2) Remove the waste toner box.

Signal name Name Function/Operation

DVM_CL Developing drive motor (Color) Color developing unit/Color drum drive

DVM_K Developing drive motor (Black) Black developing unit/Black drum drive

BS Developing bias (Y,M,C,K) Developer bias

TCS Toner density sensor (Y,M,C,K) Controls the toner density in the developing unit.

No. Name Function/Operation

1 Developer roller Latent electrostatic images on the OPC drum are changed to visible images.

2 Mixing roller Mixing of developer

3 Toner filter (Y,M,C,K) Prevents dispersing of toner

Parts

a Density sensor

a

2

1

Loading...

Loading...