MX-5001N ADJUSTMENTS 5 – 46

4) Check the adjustment pattern to confirm that the items below

are in the range of the standard values.

If the above condition is not satisfied, or if it is set to a desired

condition, execute the simulation 50-1.

(Note) Feed paper from all the paper feed trays to confirm.

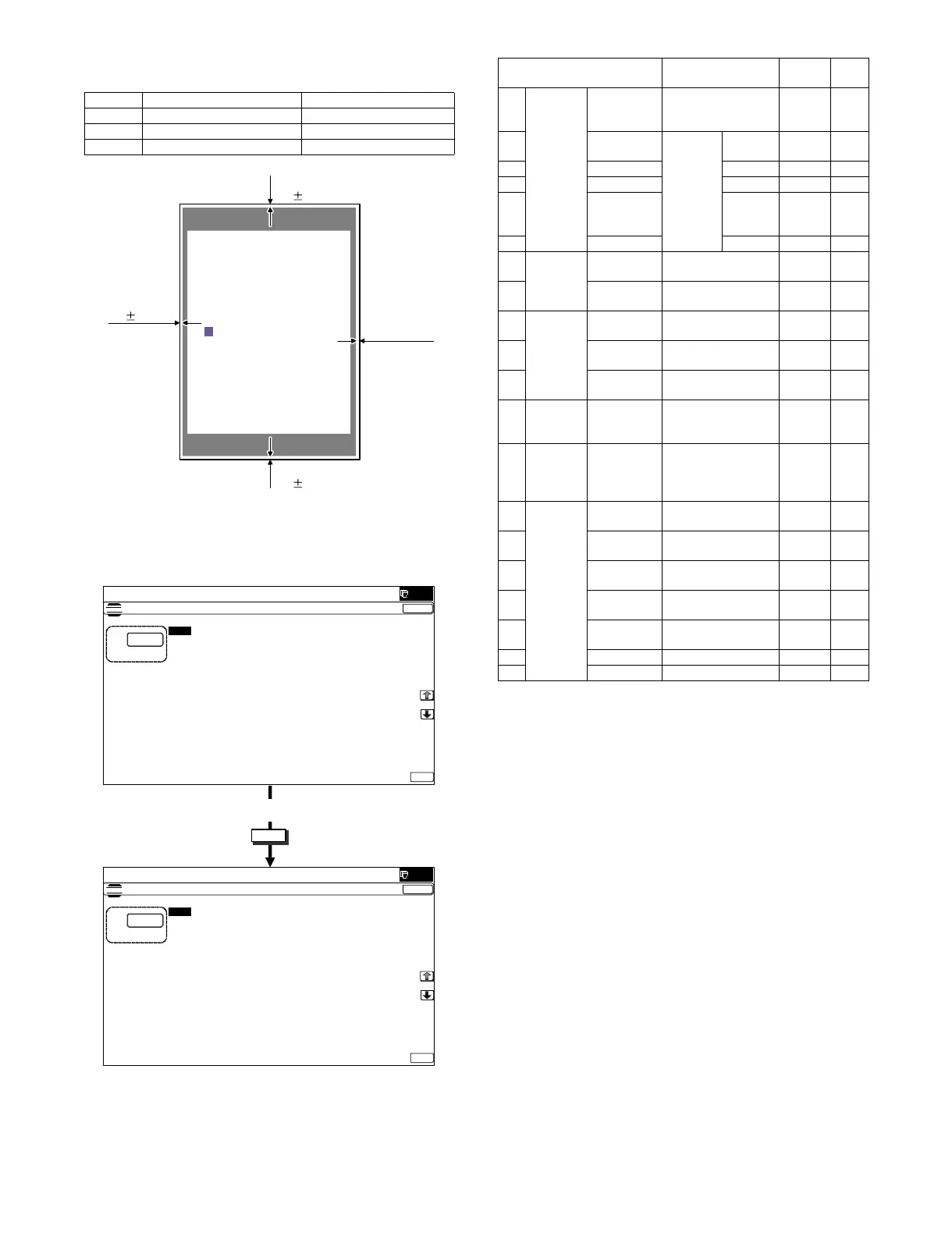

5) Go through the modes specified in Simulation 50-1.

6) Select the adjustment item I, J, K with the scroll key, and enter

the adjustment value and press [OK] key.

When the adjustment value is increased, the void area is

increased. When the adjustment value is decreased, the void

area is decreased.

When the adjustment value is changed by 1, the void area is

changed by 0.1mm.

NOTE: The adjustment value and the actual void area are related

as follows:

Adjustment value/10 = Actual void area

NOTE: When the amount of the rear edge void is different between

each paper feed tray, change the adjustment value of item

N, O, P, Q, R, S, T (DENB-XXX) in SIM50-1 and adjust.

The adjustment item J (DENB) have a effect on the paper

of all paper feed tray.

That is, adjustment value of item N, O, P, Q, R, S, T

(DENB-XXX) fine adjusts to adjustment item J (DENB) for

each paper tray.

After execution of the above, perform procedures 1) - 4) to check

that the void area is within the specified range.

Though the lead edge void area adjustment value is proper, if the

lead edge void area is not within the specified range, change the

adjustment value of RRCB-XXX (item B, C, D, E, F) of SIM 50-1.

Repeat the above procedures until a satisfactory result is obtained.

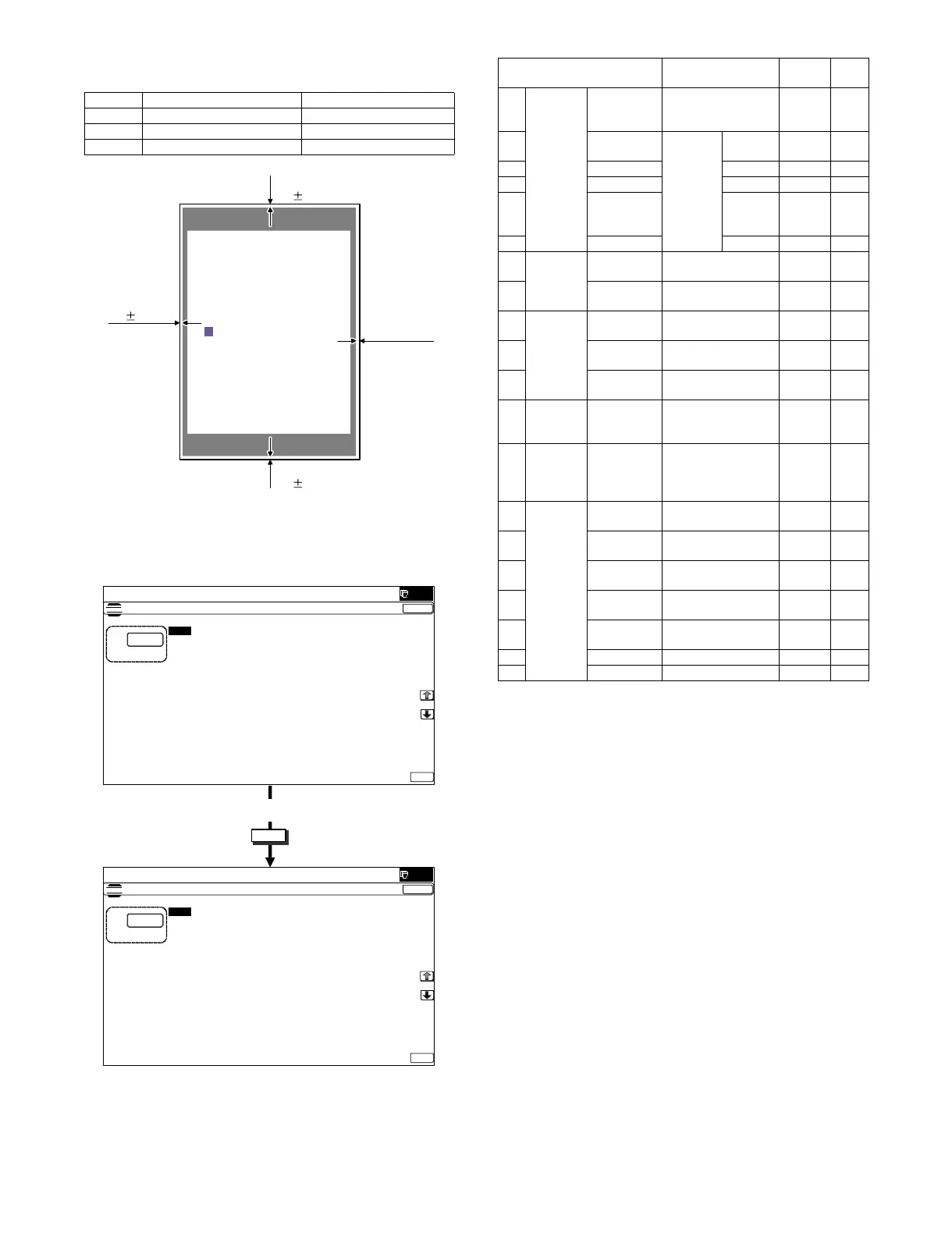

Content Standard adjustment value

X Lead edge void area 3.0 ± 1.0mm

Y Rear edge void area 2.0 - 5.0mm

Z1/Z2 FRONT/REAR void area 2.0 ± 2.0mm

X

Y

Z2

2.0

3.0 1.0mm

2.0 - 5.0mm

Z1

2.0

2.0mm

2.0mm

OK

10-key

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

/($'('*($'-8670(179$/8(

$˖

˷˹

˖55&$

$˖

˖55&%&6

%˖

˖55&%&6

&˖

˖55&%/&&

'˖

˖55&%$'8

)˖

˖55&%0)7

(˖

˖/($'

*˖

˖6,'(

+˖

˖'(1$

,˖

˖'(1%

-˖

˖)52175($5

.˖

2.

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

/($'('*($'-8670(179$/8(

$˖

˷˹

˖55&$

$˖

˖55&%&6

%˖

˖55&%&6

&˖

˖55&%/&&

'˖

˖55&%$'8

)˖

˖55&%0)7

(˖

˖/($'

*˖

˖6,'(

+˖

˖'(1$

,˖

˖'(1%

-˖

˖)52175($5

.˖

2.

Display/Item Content

Setting

range

De-

fault

A Lead

edge

adjust-

ment

value

RRCA Document lead edge

reference position

(OC)

0 - 99 50

B RRCB-CS12 Resist

motor ON

timing

adjust-

ment

Standard

Tray

1 - 99 50

C RRCB-CS34 Desk 1 - 99 50

D RRCB-LCC LCC 1 - 99 50

E RRCB-MFT Manual

paper

feed

1 - 99 50

F RRCB-ADU ADU 1 - 99 50

GImage

loss area

setting

value

LEAD Lead edge image

loss area setting

0 - 99 30

H SIDE Side image loss area

adjustment

0 - 99 20

I Void area

adjust-

ment

DENA Lead edge void area

adjustment

1 - 99 30

J DENB Rear edge void area

adjustment

1 - 99 30

K FRONT/

REAR

FRONT/REAR void

area adjustment

1 - 99 20

L Off-center

adjus-

tment

OFSET_OC OC document off-

center adjustment

1 - 99 50

M Magnifi-

cation

ratio

correction

SCAN_

SPEED_OC

SCAN sub scanning

magnification ratio

adjustment (CCD)

1 - 99 50

NSub

scanning

direction

print area

correction

value

DENB-MFT Manual feed

correction value

1 - 99 50

O DENB-CS1 Tray 1 correction

value

1 - 99 50

P DENB-CS2 Tray 2 correction

value

1 - 99 50

Q DENB-CS3 Tray 3 correction

value

1 - 99 50

R DENB-CS4 Tray 4 correction

value

1 - 99 50

S DENB-LCC LCC correction value 1 - 99 50

T DENB-ADU ADU correction value 1 - 99 50

Loading...

Loading...