MX-M350/M450 N/U ADJUSTMENTS 8 - 5

When the set value is increased, the warp amount of paper is

increased. When the adjustment value is decreased, the warp

amount of paper is decreased.

<4> Self print lead edge adjustment

Items which must have been completed before this adjust-

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

• Print off-center adjustment

• Resist amount adjustment

Items which must be executed after completion of this adjust-

ment.

• Front/rear and left/right void amount setting

• OC scan lead edge adjustment

• SPF scan lead edge adjustment

1) Execute SIM 50-5.

2) Set the lead edge void adjustment value (DENA) as specified

below.

(Standard set value) Paper lead edge void: 3.5mm (DENA: 35)

∗ Set the adjustment value of DENA to 35. (Enter 35 as the

adjustment value of DENA, and press [P] key.)

3) Check the lead edge void area on the self print pattern

(SIM67-1).

(Enter 1 and press [START] key.)

4) If the adjustment result is not satisfactory, perform the follow-

ing procedures.

∗ If the lead edge void area is not 3.5mm:

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.)

(Shift for the adjustment value change: 0.1mm/step)

<Specification>

<5> Front/rear and left/right void amount setting

Items which must have been completed before this adjust-

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

• Print off-center adjustment

• Resist amount adjustment

• Print lead edge adjustment

Items which must be executed after completion of this adjust-

ment.

• OC scan lead edge adjustment

• SPF scan lead edge adjustment

1) Execute SIM 50-1.

(Lead edge image loss/void area adjustment)

1) Set the lead edge image loss adjustment value (LEAD EDGE)

and the paper lead edge void adjustment value (DENA) as fol-

lows.

(Standard set value)

Lead edge image loss: 1.5mm (LEDA: 15)

Paper lead edge void: 3.5mm (DENA: 35)

∗ Set LEAD to 15. (Enter 15 as the adjustment value of LEAD,

and press [P] key.) (0.1mm/step)

∗ Set DENA to 35. (Enter 35 as the adjustment value of

DENA, and press [P] key.) (0.1mm/step)

2) Make a copy at the normal ratio (100%) and check the lead

edge void area and the image loss. (Enter 100 as the set value

of the copy magnification ratio (MAGNIFICATION), and press

[START] key.)

3) If the adjustment result is not satisfactory, perform the follow-

ing procedures.

∗ If the lead edge void are is not 3.5mm:

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.) (1msec/step)

∗ If the lead edge image loss is not 1.5mm:

Change the adjustment value of RRCA and perform the

adjustment. (Change the adjustment value of RRCA and

press [START] key.)

(Shift for the adjustment value change: 0.2mm/step)

(Rear edge void area adjustment)

Adjust so that the rear edge void area is 3.5mm. (Change the

adjustment value of TRAIL EDGE, and press [START] key.)

(Front/rear frame direction image loss adjustment)

Set the adjustment value of SIDE to 20. (Enter 20 as the adjust-

ment value of SIDE, and press [P] key.)

When the adjustment value is changed, the image position is

shifted in the front/rear frame direction.

(Front/rear frame direction void area adjustment)

Adjust so that the total of the front/rear direction void areas is

7.0mm. (Change the adjustment values of FRONT/REAR, and

press [START] key.)

Front frame void area = 3.5mm Rear frame void area = 3.5mm

If, as shown above, the front and the rear void areas are not even,

use SIM 50-5 to adjust the image off-center position.

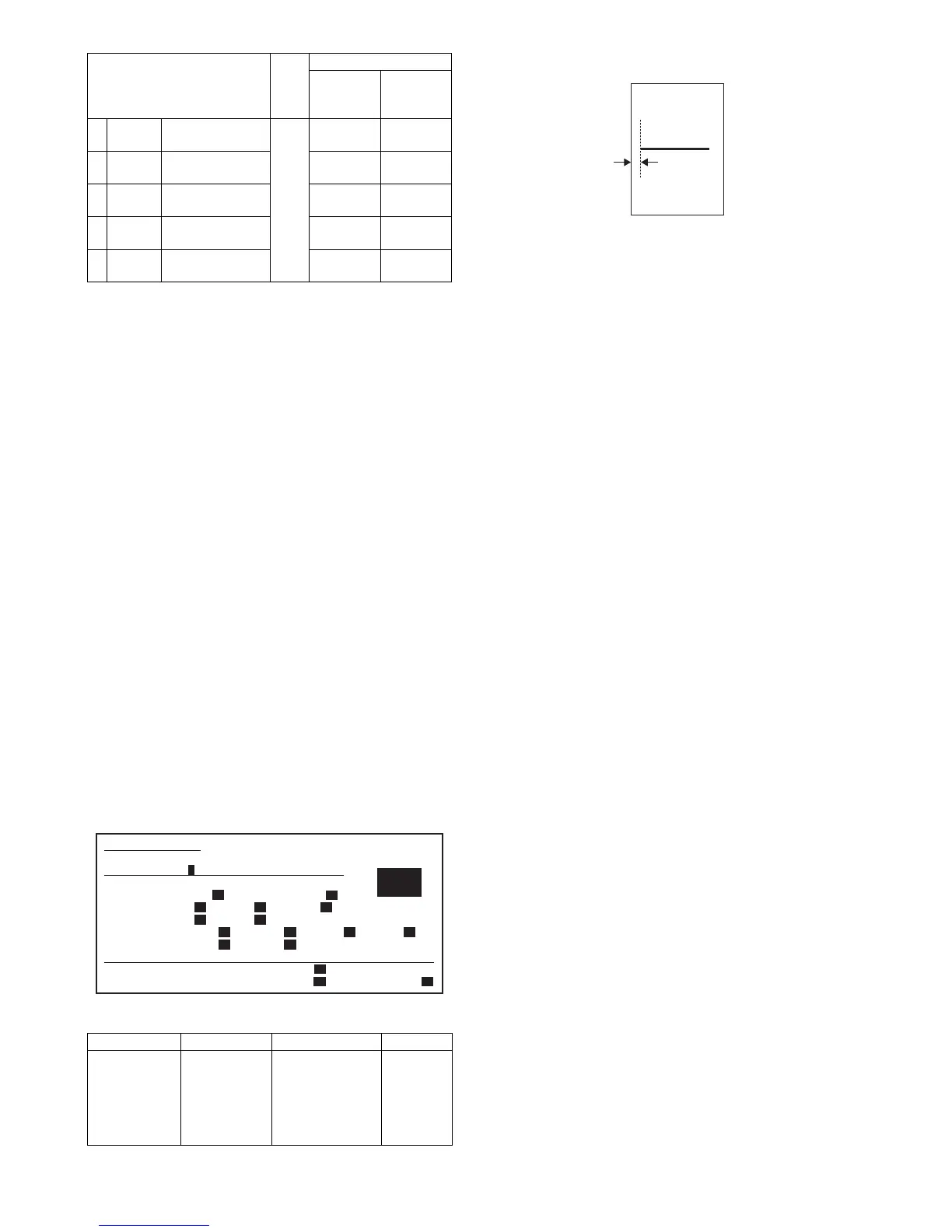

Item

Set

range

Default

MX-

M350U/

M350N

MX-

M450U/

M450N

2 TRAY1 Tray 1 resist

adjustment value

0 - 99 65 60

3 TRAY2 Tray 2 resist

adjustment value

55 50

4 DESK Desk resist

adjustment value

55 50

5 BPT Manual tray resist

adjustment value

60 55

6 ADU ADU resist

adjustment value

55 50

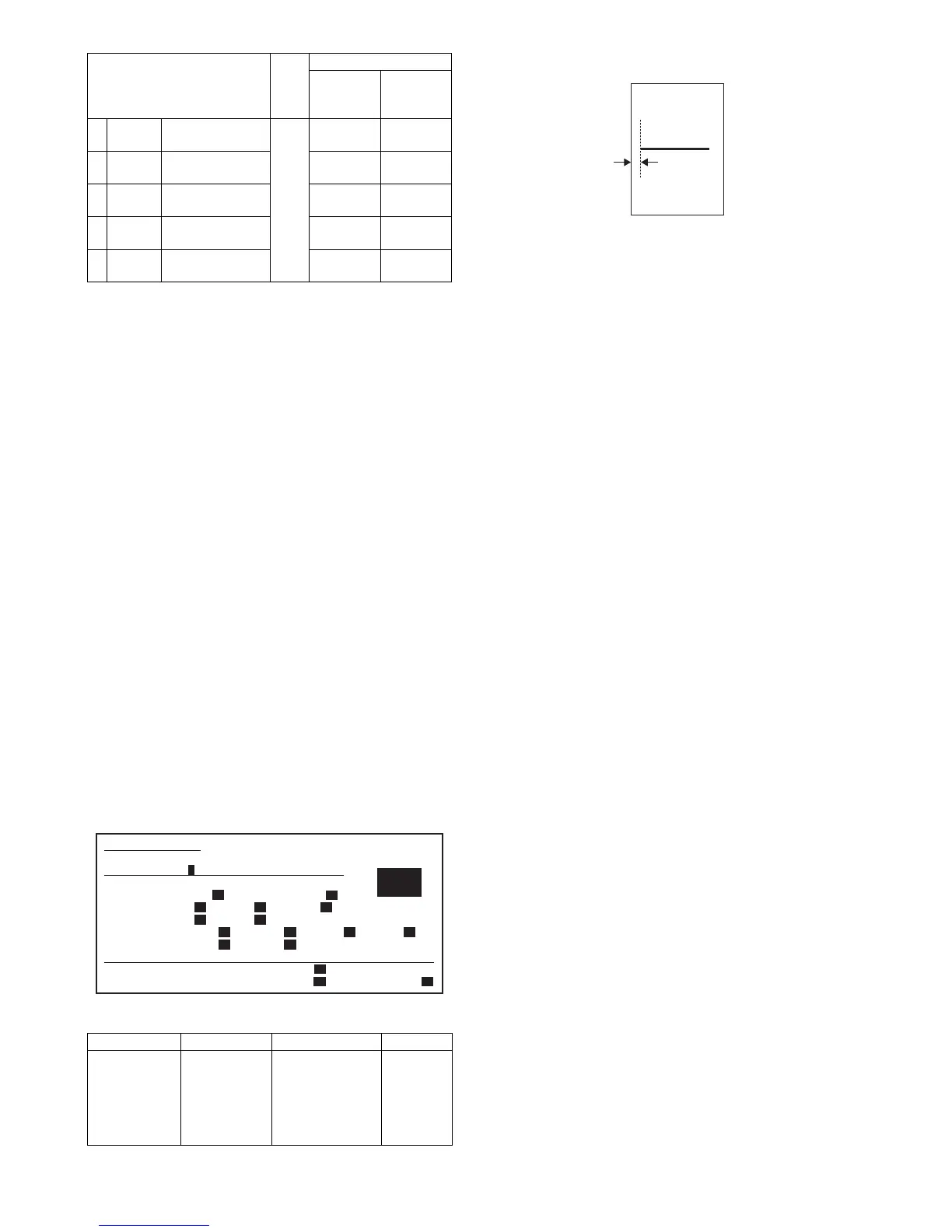

Set position Specification Set value

Self print lead

edge

adjustment

SIM 50-5

Print start

position A of

the output

pattern 1

A = 4.0mm or less

(Lead and tail

total: 8.0mm or

less)

Shift of

0.175mm

(35ppm) /

0.225mm

(45ppm) for

set value 1.

2

SIMULATION 50-5

LEAD EDGE ADJUSTMENT. SELECT 0-20, AND PRESS START.

0.TRAY SELECT 1 1.PRINT START

(ADJUSTMENT DATA)

LEAD EDGE: 2.RRCB 50 3.SIDE2 ADJ. 50

RESIST: 4.T1 50 5.T2 50 6.DESK 50

7.BPT 50 8.ADU 50

OFF CENTER: 9.T1 50 10.T2 50 11.T3 50 12.T4 50

13.BPT 50 14.ADU 50

(VOID SETTING) 15.LEAD_EDGE(DENA) 50

16.TRAIL_EDGE(DENB) 30 17.FRONT/REAR 30

A

[Output pattern]

Loading...

Loading...