MX-M350/M450 N/U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 1

[7] MAINTENANCE AND DETAILS OF EACH SECTION

• Self print of set values

Use of SIM 22-6 allows to print the set values and the jam his-

tory of the machine.

These values must be printed before execution of maintenance

or disassembly procedures.

• When assembling, check that the flat cable and the harness

connectors are securely connected.

• When connecting the flat cable, be careful not to break the pins.

When installing the PWB unit and the memory module, use a

Ground Strap to prevent damage caused by electrical dis-

charge.

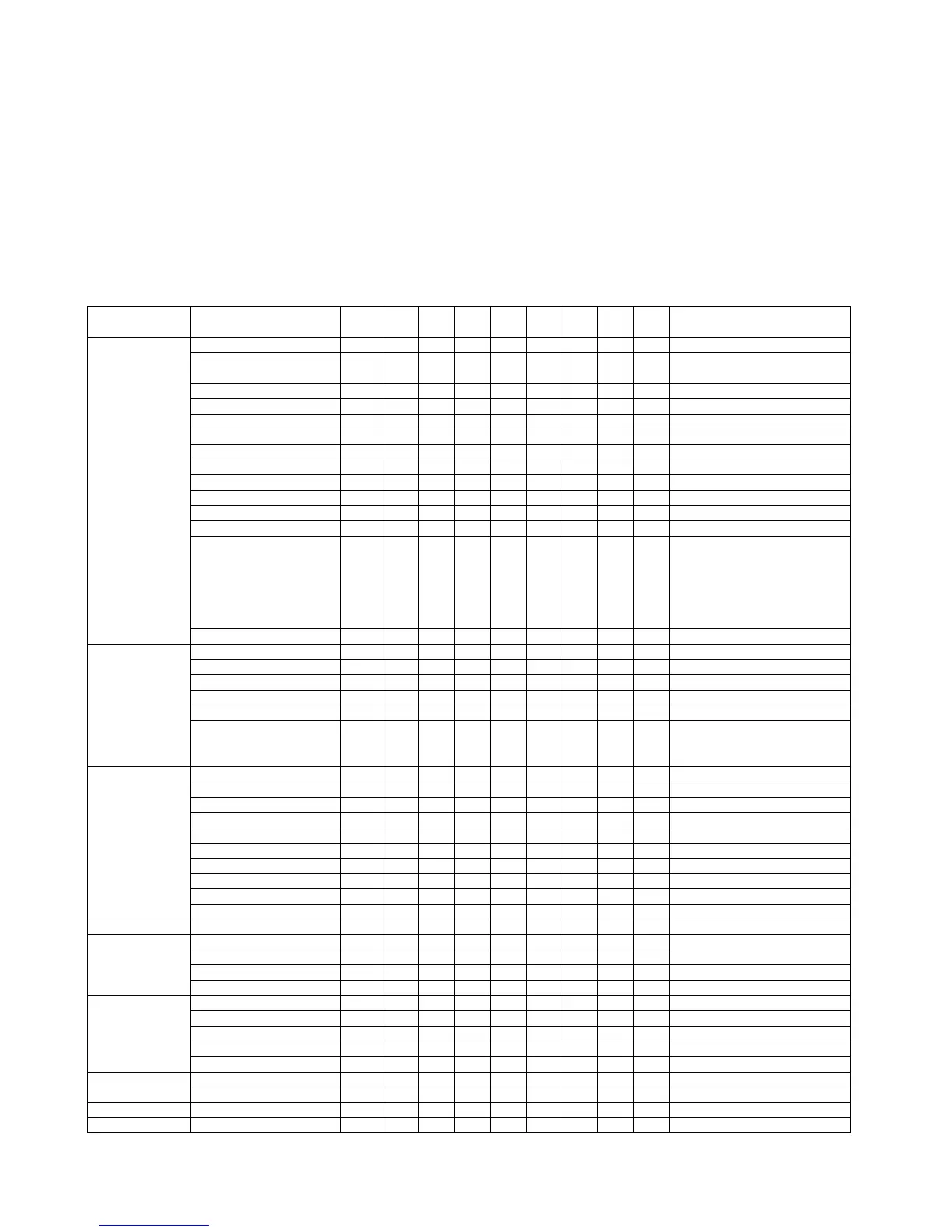

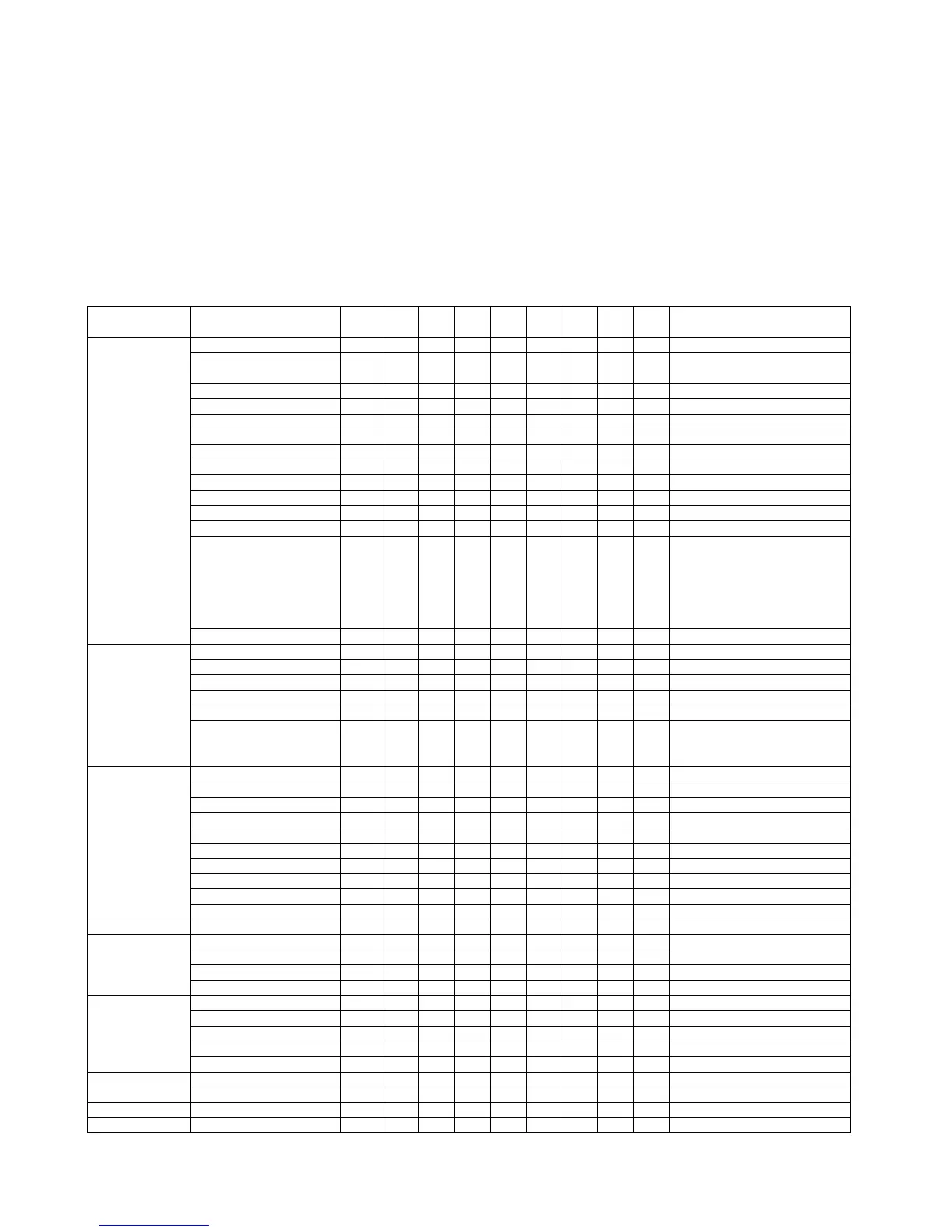

[Maintenance System Table]

1. Engine section

Maintenance cycle : 200K

✕ Check (Clean, replace, or adjust as necessary.) ❍ Clean ▲ Replace ∆ Adjust ✩ Lubricate ❏ Move position

Unit name Part name

When

calling

100K 200K 300K 400K 500K 600K 700K 800K Remark

Drum peripheral Drum ✕▲✕▲✕▲✕▲

Cleaner blade ✕▲✕▲✕▲✕▲Replace at 200K or 1 year.

P/G No.: [10]-49

Toner reception seal ✕▲✕▲✕▲✕▲P/G No.: [10]-42

Side molt F ✕▲✕▲✕▲✕▲P/G No.: [10]-33

Side molt R ✕▲✕▲✕▲✕▲P/G No.: [10]-37

Transfer roller ✕ ✕▲✕▲✕▲✕▲P/G No.: [5]-8

Discharge plate ✕ ✕▲✕▲✕▲✕▲P/G No.: [5]-2

TR bearing (F/R) ✕✕✕▲✕✕✕▲P/G No.: [5]-9, 18

Transfer roller collar ✕✕✕▲✕✕✕▲P/G No.: [5]-10

After-transfer star ring ✕✕✕✕✕✕✕✕P/G No.: [5]-19

TR gear ✕ ✕▲✕▲✕▲✕▲P/G No.: [5]-15

Drum separation pawl unit ✕▲✕▲✕▲✕▲P/G No.: [5]-501

MC unit ✕ ❍▲❍▲❍▲❍▲Includes the screen grid, the

charging plate, and the MC

cleaner.

❍: Charging plate cleaning by

the MC cleaner

P/G No.: [9]-901

Paper guide ❍ ❍❍❍❍❍❍❍❍

Developing

section

Developer ▲▲▲▲▲▲▲▲Supplied when installing

DV blade ✕▲✕▲✕▲✕▲P/G No.: [11]-55

DSD collar ❍❍❍❍❍❍❍❍

DV side seal F ✕▲✕▲✕▲✕▲P/G No.: [11]-38

DV side seal R ✕▲✕▲✕▲✕▲P/G No.: [11]-43

Toner cartridge ––––––––

Attached when installing./

750g, user replacement for every

35K.

Fusing section Upper heat roller ✕ ✕▲✕▲✕▲✕▲P/G No.: [7]-46

Lower heat roller ✕ ✕▲✕▲✕▲✕▲P/G No.: [7]-22

Upper separation pawl ❍ ❍▲❍▲❍▲❍▲P/G No.: [7]-3

Lower separation pawl ❍ ❍▲❍▲❍▲❍▲P/G No.: [7]-41

Thermistor ✕ ✕✕✕✕✕✕✕✕Clean and remove paper dust.

Upper heat roller gear ✕▲✕▲✕▲✕▲P/G No.: [7]-47

Paper guides ❍ ❍❍❍❍❍❍❍❍

Gears ✩✩✩✩✩✩✩✩

CL roller ✕ ✕▲✕▲✕▲✕▲P/G No.: [7]-52

CL roller bearing ✕ ✕▲✕▲✕▲✕▲P/G No.: [7]-53

Filters Ozone filter ▲▲▲▲▲▲▲▲P/G No.: [12]-2

Paper feed

section

Pick-up roller ✕ ✕✕✕✕✕✕✕✕Note 1

Paper feed roller ✕ ✕✕✕✕✕✕✕✕Note 1

Separation roller ✕ ✕✕✕✕✕✕✕✕Note 1

Torque limiter ✕ ✕✕✕✕✕✕✕✕Note 1

Transport section

Paper exit

reverse section

Resist roller ✕ ❍❍❍❍❍❍❍❍

Transport rollers ✕ ❍❍❍❍❍❍❍❍

Transport paper guides ❍ ❍❍❍❍❍❍❍❍

Paper dust remover unit ❍ ❍▲❍▲❍▲❍▲P/G No.: [14]-51

Optical reflection sensor ❍ ❍❍❍❍❍❍❍❍PS roller unit section

Drive section Gears (Specified position) ✕ ✩✩✩✩✩✩✩✩

Belts ✕ ✕✕✕✕✕✕✕✕

Image quality ✕ ✕✕✕✕✕✕✕✕

Other Sensors ✕✕✕✕✕✕✕✕Clean with air.

Note 1: Replacement reference:Use the counter value of each paper feed port as the replacement reference.

Paper feed roller/Separation pad/Torque limiter section (Include Desk, Multi purpose): 100K or 1 year

Loading...

Loading...