10

2687

12 2020

-

SE80 & SE100 & SE120 & SE130 & SE150

MG_0002

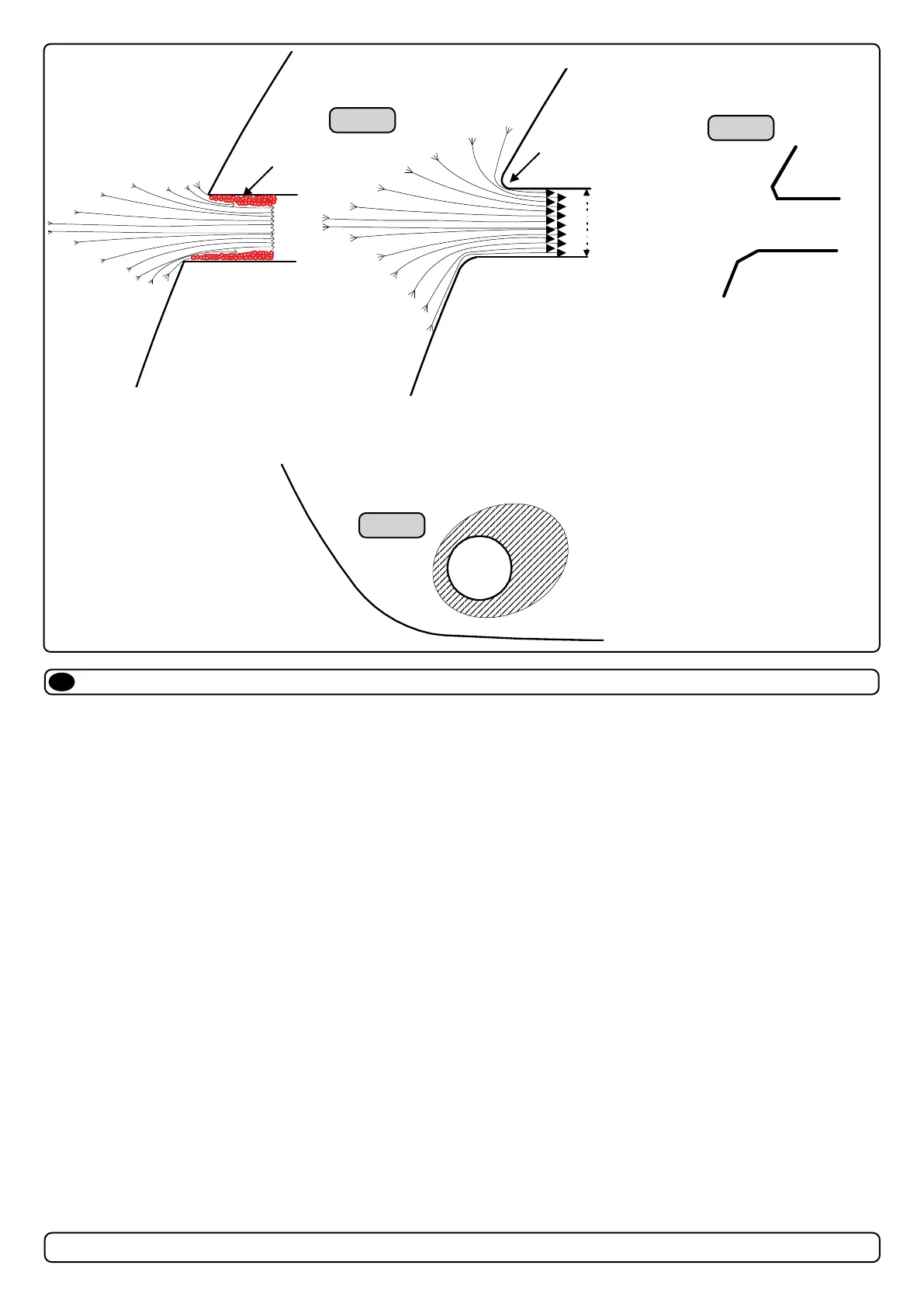

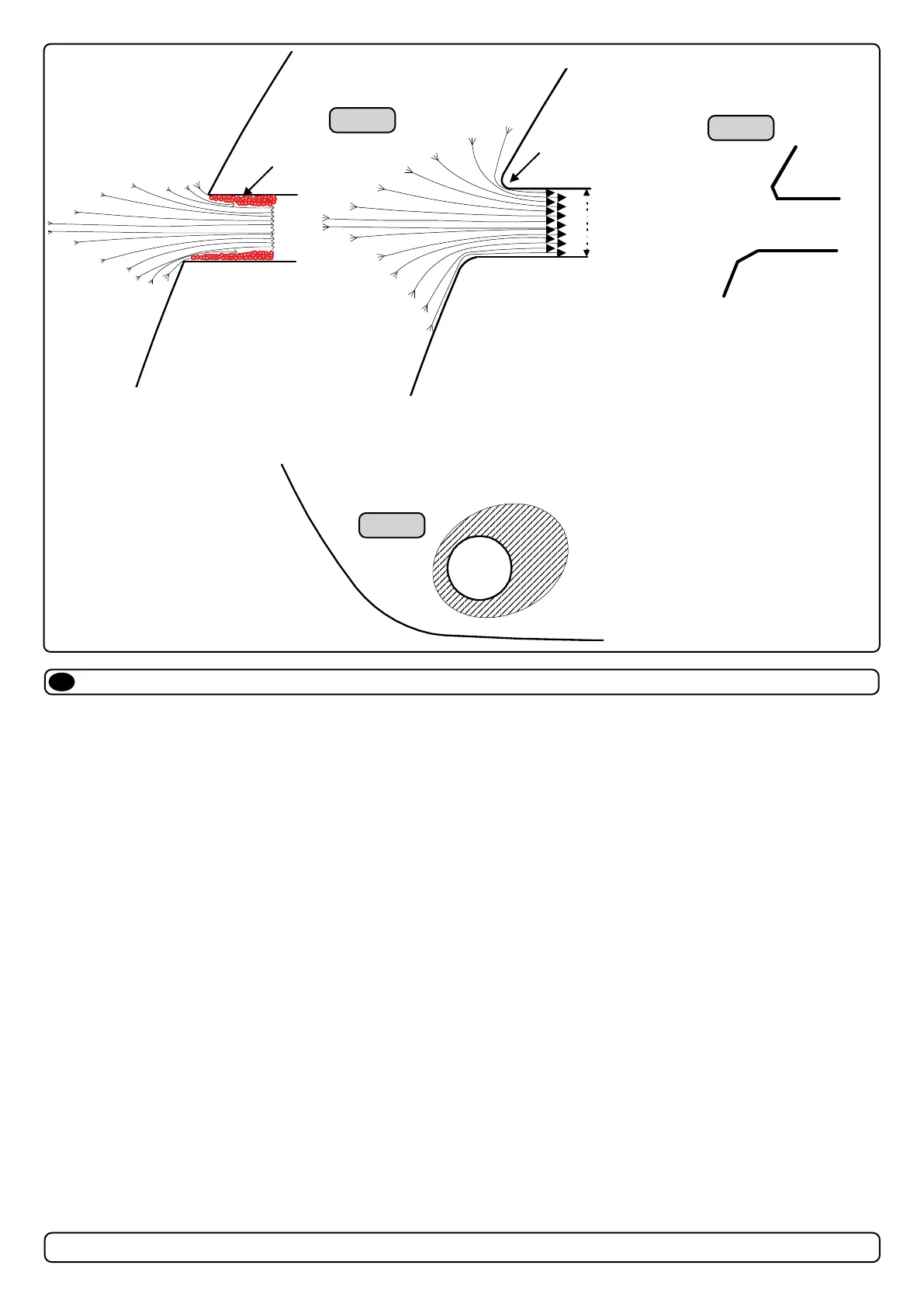

R = 0,1 x D (10%)

D

1

2

3

Angled tunnel ends for

steel/ aluminium hulls

Cavitation

MG_0003

High water force

while underway

High water force

while underway

from wave contact

1 2 3

4

Tunnel ends

EN

MC_0003

Rounded tunnel ends will maximise thrust and minimise noise and cavitation.

For best performance round the tunnel connection to the hull-side as much as possible. The minimum rounding has a radius of 10% of the diameter of

the tunnel.

Signi cant advantages of a rounded tunnel over a sharp tunnel to hull connections are:

1. A rounded tunnel end will prevent the creation of turbulence/ cavitation created from a sharp tunnel end when water passes by the tunnel.

- The turbulence/ cavitation will block the outer area of the tunnel and thereby reduces the eff ective tunnel diameter and thrust.

- Turbulence/ cavitation on the propeller will lessen the thrusters performance and create excess noise.

2. For steel/ aluminium hulls angled tunnel ends also off er similar performance as a rounded connection.

3. A rounded tunnel end makes the thruster draw water from along the hull-side, creating a vacuum that will suck the boat sideways and thereby give

additional thrust.

- With a sharp tunnel end, the thruster will be unable to take water from along the hull-side, and you will not gain the desired vacuum and

additional thrust. This “free” extra thrust in optimal installations be 30 - 40% of the total thrust.

(NB: A Side-power thruster propeller does not produce cavitation at working speed. Therefore, any cavitation and cavitation noise in the

tunnel will be caused during improper tunnel installation.)

Loading...

Loading...