17

2687

12 2020

-

SE80 & SE100 & SE120 & SE130 & SE150

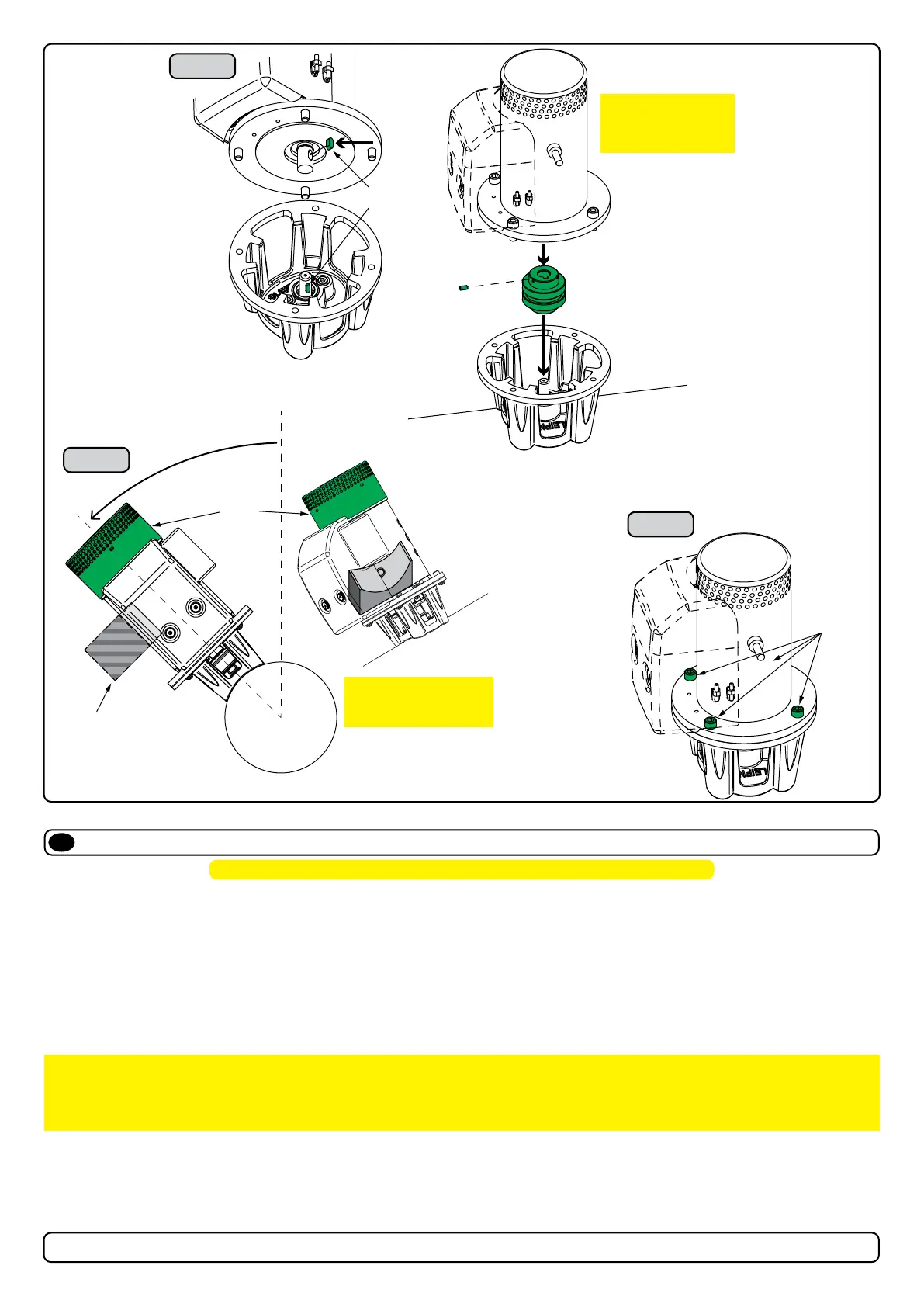

Motor Installation

EN

1. Install the motor onto the motor bracket ensuring the couplings are engaged together correctly (top and bottom). (NB: The motor can be placed

in all directions on the motor bracket. However, ensure the cable terminals are accessible for electrical installation later.)

2. If you are installing the motor at an angle of more than 30º off vertical, the motor will require separate/ additional support. (NB: Do not position

supports on the motors top cap.)

3. Fasten the bolts holding the motor to the motor bracket with the above torque.

4. Check the drive shafts are engaged by rotating the propeller. (NB: Rotating the propellers can be hard due to the gear reduction and the

motor, however the propeller must be able to rotate via hand power.)

MC_0019

! Please refer to the graphic for special considerations relating to your model !

IMPORTANT

The thruster motor assembly must be protected using suitable covering to avoid dust/debris ingress from fabrication/maintenance/

shipbuilding operations. On completion of operations, the cover must be removed before operating the thruster.

MG_0043

1

2

3

IMPORTANT

Do not position support

on the motor cap.

FASTEN

(33 Nm)

(24 lb/ft)

Motor support

Motor

Cap

> 30°

Holding Key

IMPORTANT

Ensure the holding

key and coupling are

aligned when fitted

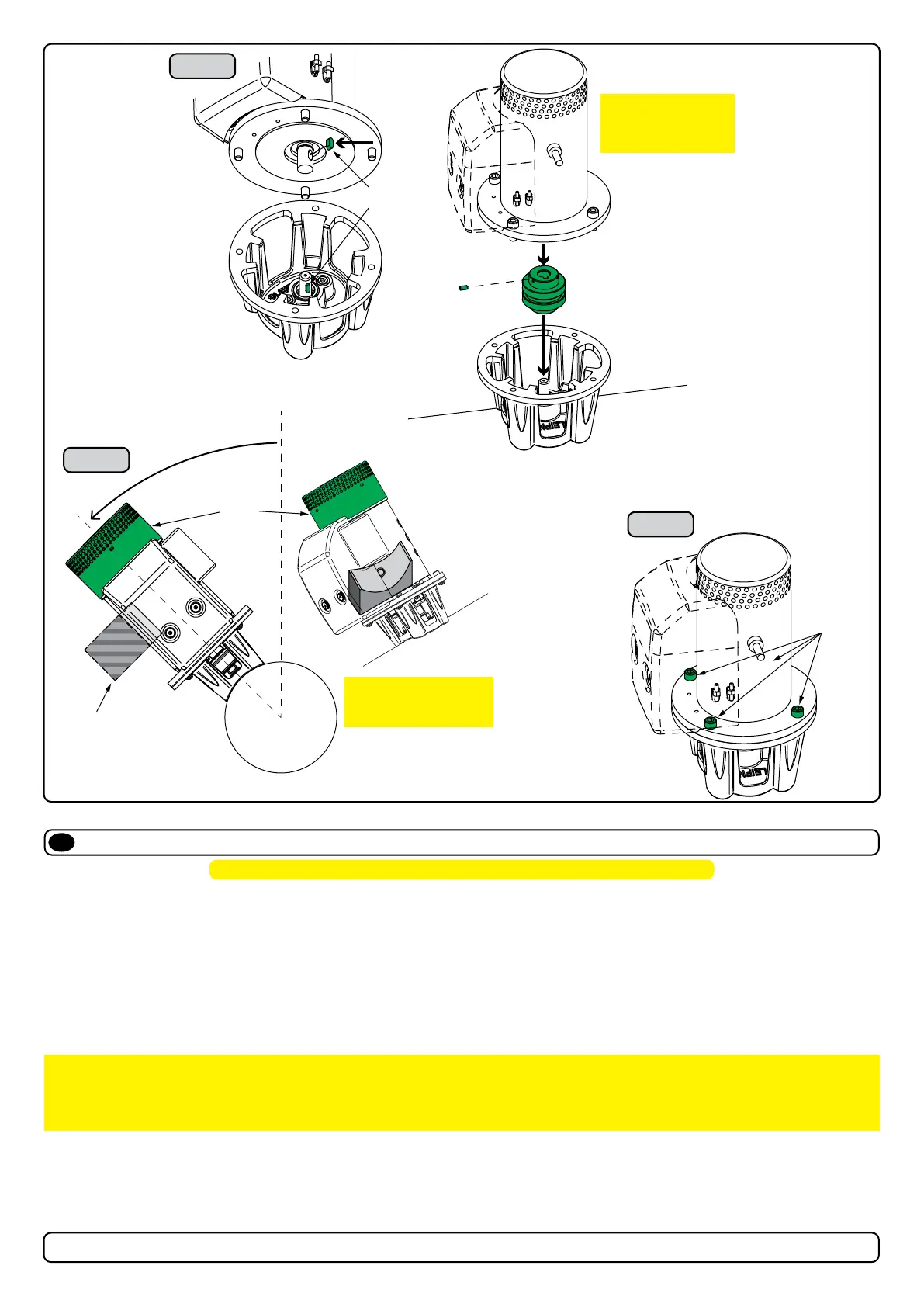

Propeller Installation

EN

MC_0018

! Please refer to the graphic for special considerations relating to your model !

1. Centre the drive pin and Insert the propeller onto the shaft spine. Rotate the propeller until the drive pin aligns with the internal slot in the propeller.

2. Insert the washer to the end of the shaft spline. Tighten with the propeller lock-nut.

3. Insert the anode to the end of the propeller and tighten the anode holding screw. Apply a thread glue (Loctite 243 or similar) to ensure that the

anode holding screw does not un-screw itself from during the rotation of the propeller.

4. Apply antifouling to the gear leg and propeller. Do not apply antifouling to any rubber elements of the gear leg or anodes.

MG_0033

DRIVE PIN

PROPELLER

WASHER

LOCK NUT

ANODE

ANODE HOLDING

SCREW

Apply Loctite 243 or similar

Anitfouling

Loading...

Loading...