12

2687

12 2020

-

SE80 & SE100 & SE120 & SE130 & SE150

MG_0005

R

D

1 2

3

4

6

5

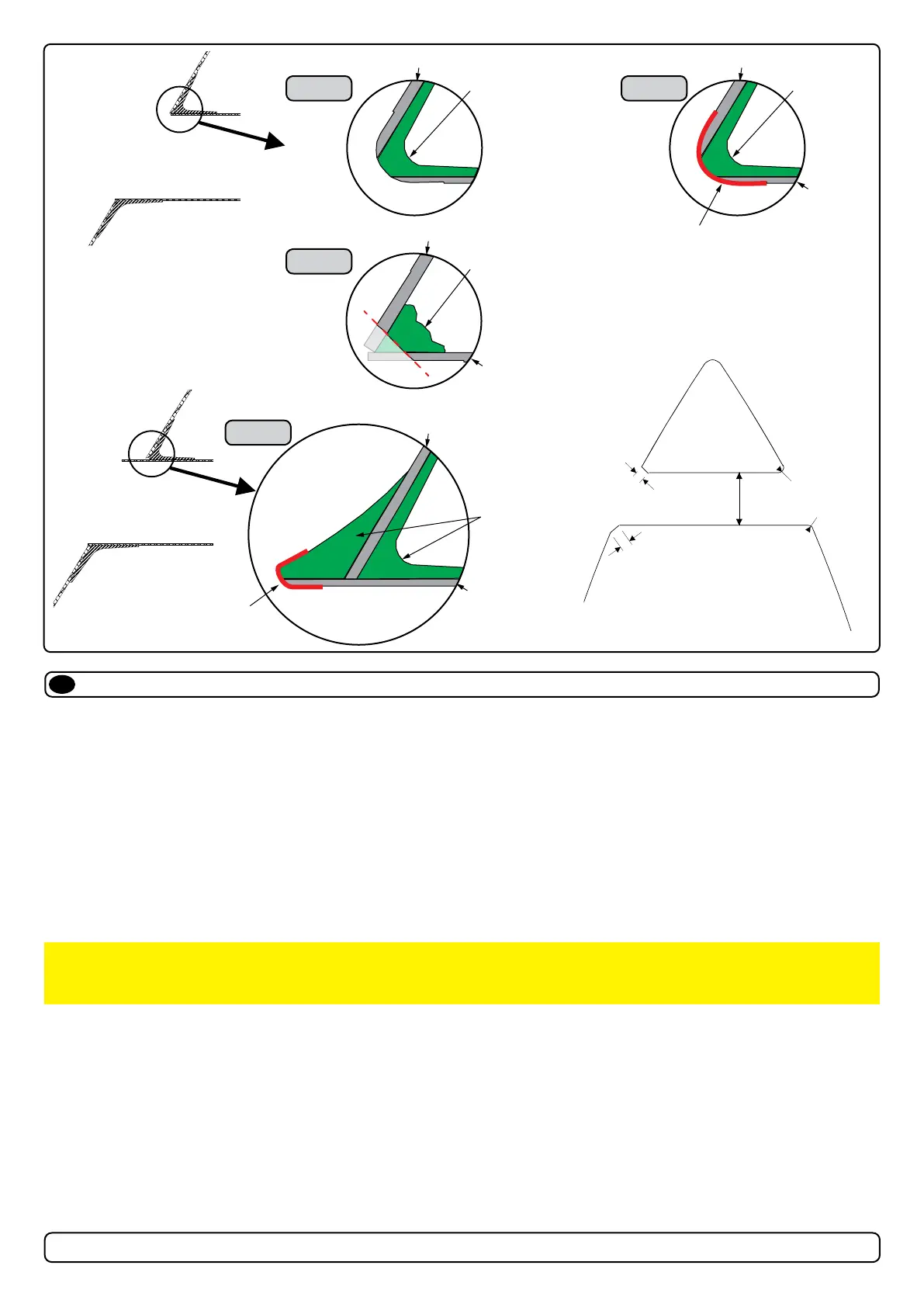

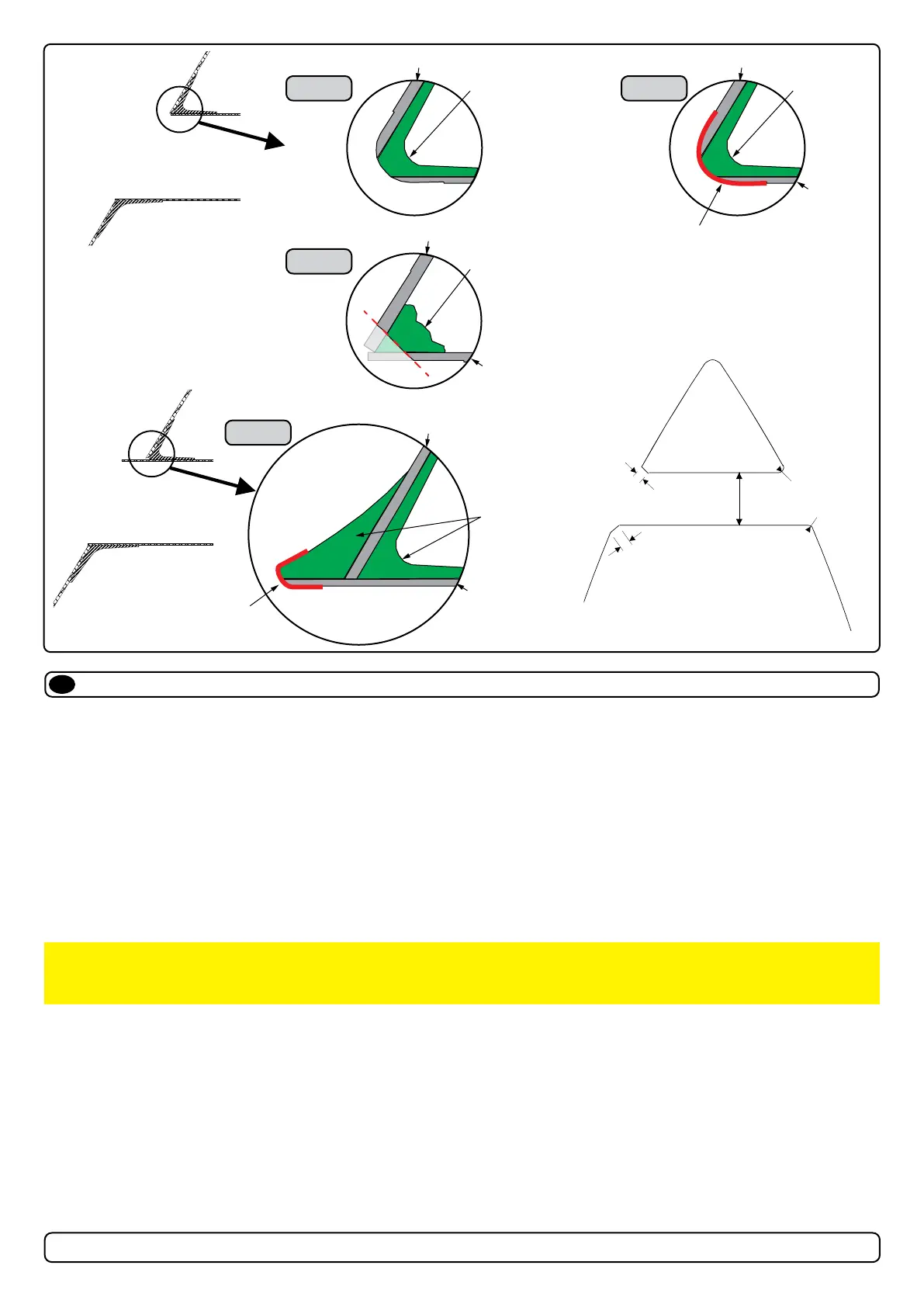

8 x layers of fibreglass

and resin

8 x layers of fibreglass

and resin

MG_0006

R = D x 0,1

R = D x 0,1

D

x

0

,

1

-

0

,

1

5

D

x

0

,

1

-

0

,

1

5

D

Layers of

fibreglass

and resin

Layers of

fibreglass

and resin

*Fibreglass

Hull

*Steel/

Aluminium

Hull

Hull

Hull

Hull

Tunnel

Tunnel

Tunnel

Welding

Layers of

fibreglass

and resin

Additional Layers of

fibreglass and resin

Additional Layers of

fibreglass and resin

Hull

1 3

4

2

IMPORTANT

Avoid all casting where the motor-bracket is to be placed, as this will cause misfi t and possible failure to the gear house.

Tunnel installation

EN

With tunnel installed and cast.

1. Round the edges with a radius of 10% of the tunnel diameter.

2. For steel/ aluminium hulls make a slope with a length of 10-15% of the tunnel diameter.

(NB: If this is not possible, round the tunnel end as much as possible.)

3. Additionally cast two layers on the outside of the tunnel/ hull in a 10cm area

4. Follow the same method if making the de ector/ spoiler.

You must apply gel coat to areas you have grounded/ moulded to make waterproof. These areas allow water access

to the hull which is typically not waterproof without these applications outside. (NB: All original Side-Power tunnels are fully waterproof when

delivered except in the areas where you have cut and bonded it to the hull.)

MC_0003

Loading...

Loading...