Installation

5.1 Installation

Synchronous Motors 1FK7

24 Operating Instructions, 03/2011, 610.40700.40c

● Eyebolts that have been screwed in must either be tightened or removed after

installation.

● Ensure that the flange joint sits evenly; avoid applying an excessive force to fixing screws

when tightening. Use hexagon socket head cap screws with a property class of 8.8.

Observe the tightening torques for the fixing screws of the motor flange.

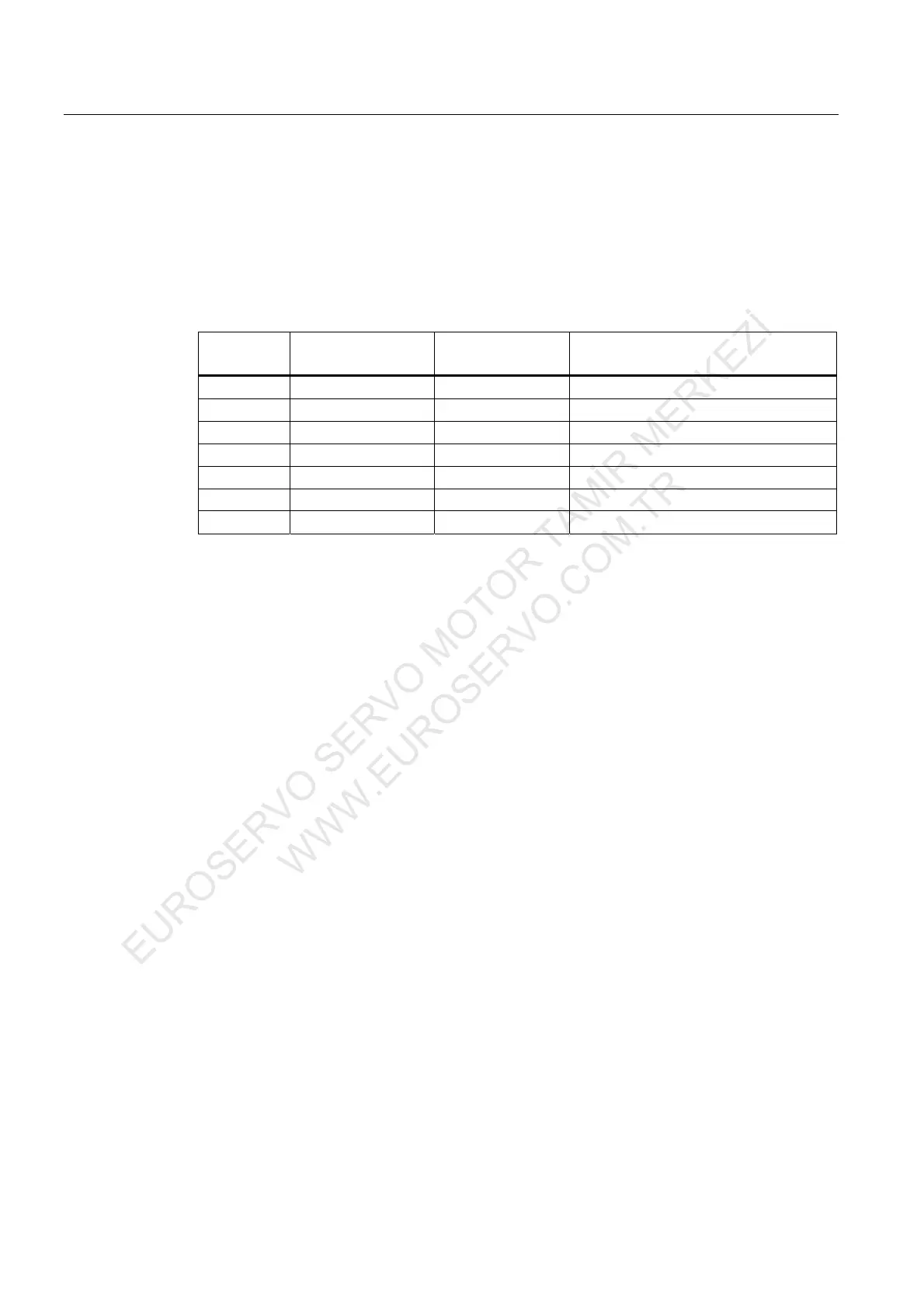

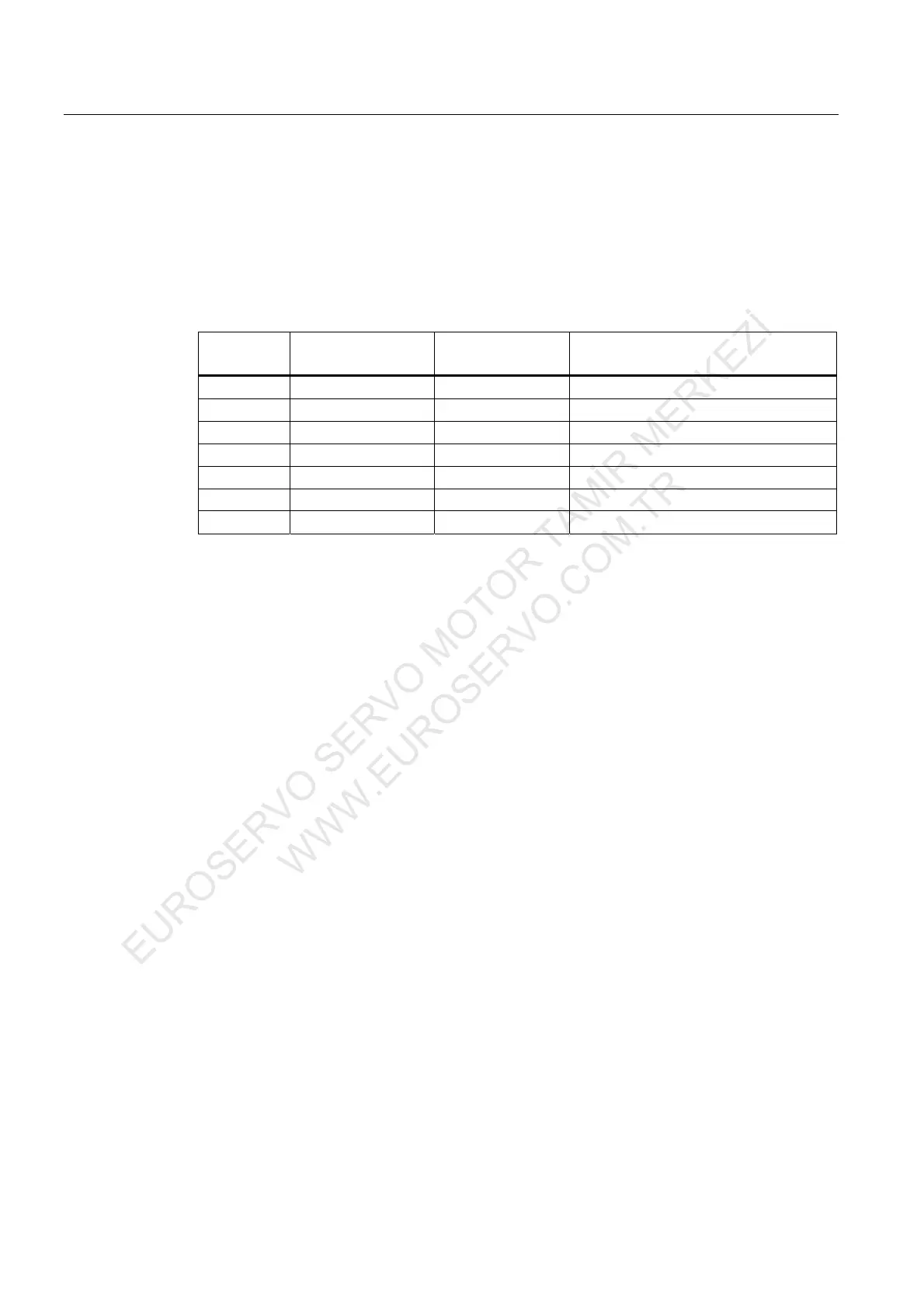

Table 5- 1 Tightening torques

Motor Screw DIN 7984 Washer ISO 7092

[mm]

Tightening torque for screws (not for

electrical connections)

1FK701 M4 4 (d2 = 8) 2.2 Nm

1FK702 M5 5 (d2 = 9) 4 Nm

1FK703 M6 6 (d2 = 11) 8 Nm

1FK704 M6 6 (d2 = 11) 8 Nm

1FK706 M8 8 (d2 = 15) 20 Nm

1FK708 M10 10 (d2 = 18) 35 Nm

1FK710 M12 12 (d2 = 20) 60 Nm

EUROSERVO SERVO MOTOR TAMİR MERKEZİ

WWW.EUROSERVO.COM.TR

Loading...

Loading...