Connecting

6.1 Electrical connection

Synchronous Motors 1FK7

32 Operating Instructions, 03/2011, 610.40700.40c

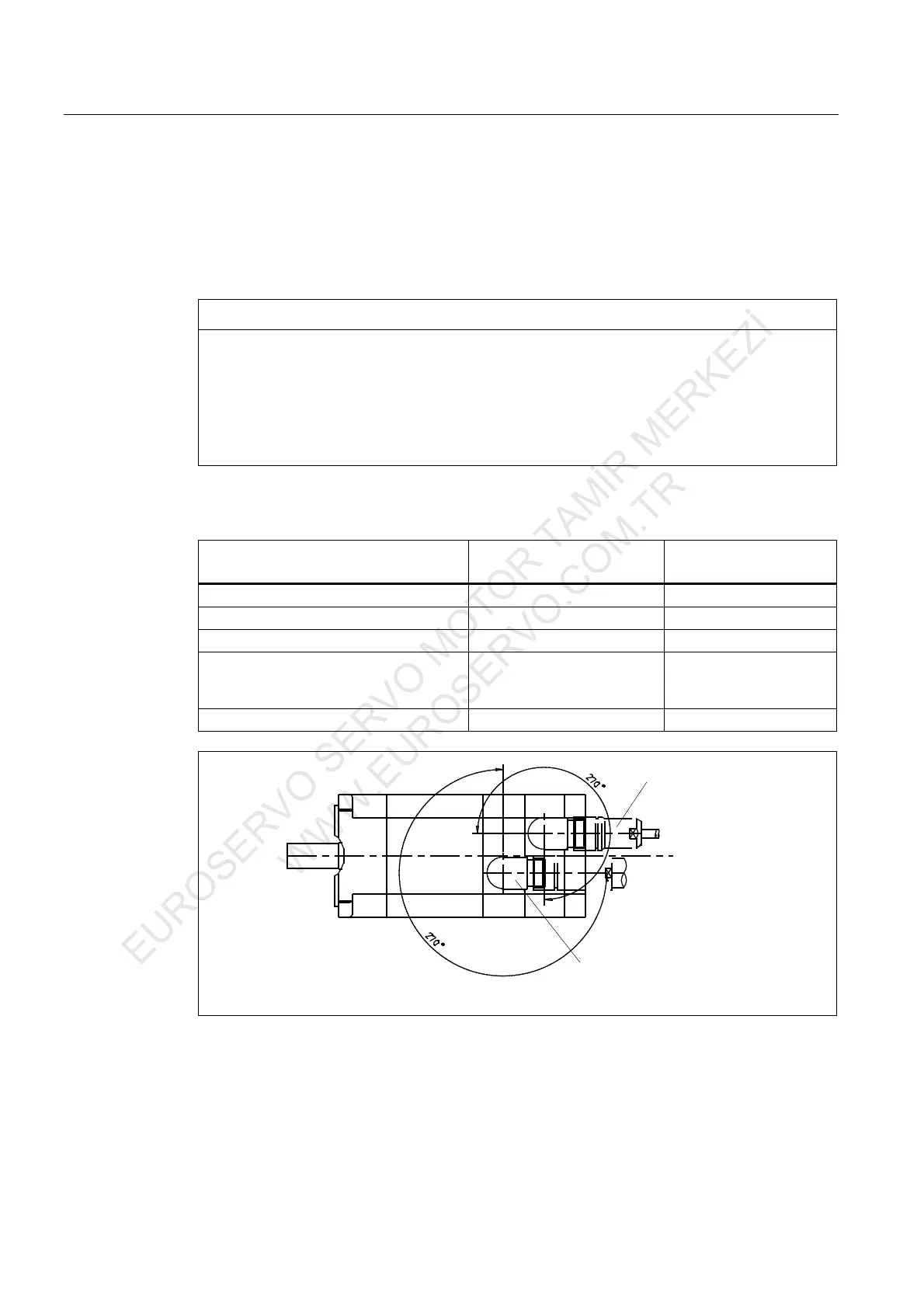

6.1.4 Rotating the connector for 1FK7xxx5 and 1FK7xxx-7

Power connectors and signal connectors can be rotated to a limited extent. A suitable socket

connector can be used to rotate the angle plug. Make sure that the socket connector is

completely secure to avoid damaging the pin contacts. For encoders with integrated Sensor

Modules (DQI) the cable outlet towards the top is fixed and cannot be changed.

NOTICE

Rotating the connectors

It is not permissible that the specified rotation range is exceeded.

In order to guarantee the degree of protection, max. 10 revolutions are permissible.

Connectors should be rotated using the matching mating connector located on the

connector thread. Only rotate Sensor Modules by hand. The use of pipe wrenches,

hammers, or similar is not permitted.

Table 6- 3 Direction of rotation and max. torque when rotating

Connectors Rotation range Max. torque when

rotating

Power connector, size 0.5 270° 8 Nm

Power connector, size 1 270° 12 Nm

Power connector, size 1.5 270° 20 Nm

Signal connector (without DRIVE-CLiQ) 230° for SH 20

180° for SH 28 ... 80

90° for SH 100

8 Nm

12 Nm

12 Nm

Signal connector (with DRIVE-CLiQ) 270° 8 Nm

3RZHUFRQQHFWRU

6LJQDOFRQQHFWRU

Figure 6-4 Ability to rotate the connector using 1FK7-5 motors as an example

EUROSERVO SERVO MOTOR TAMİR MERKEZİ

WWW.EUROSERVO.COM.TR

Loading...

Loading...