Description

3.4 Structure

1FT7 synchronous motors

Operating Instructions, 04/2010, 610.40075.40b

19

Forced ventilation

This cooling method is implemented by means of a separate ventilation module equipped

with a ventilator that operates independently of the motor. The fan is available with degree of

protection IP54.

NOTICE

Steps must be taken to ensure that the motor is always operated in conjunction with the

separately driven fan.

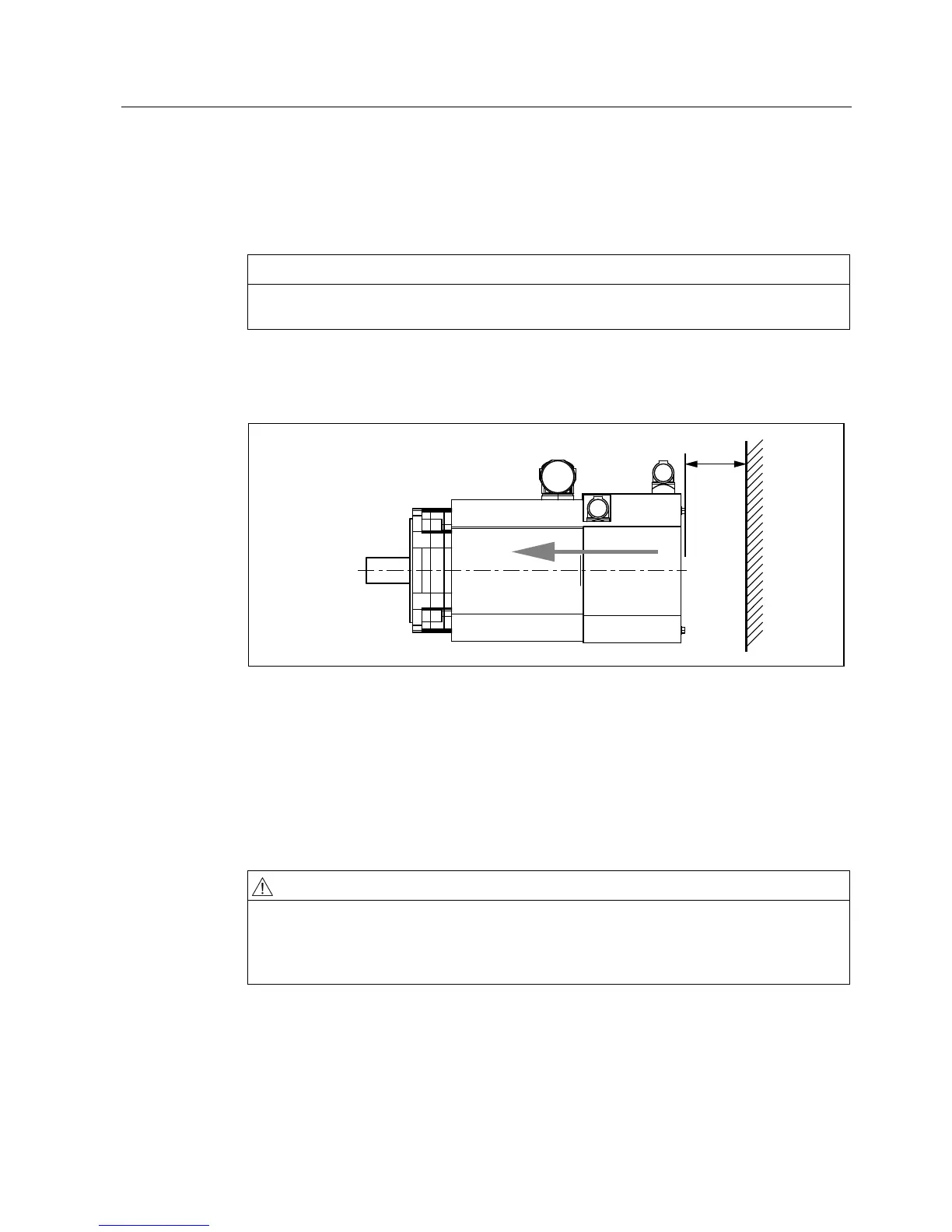

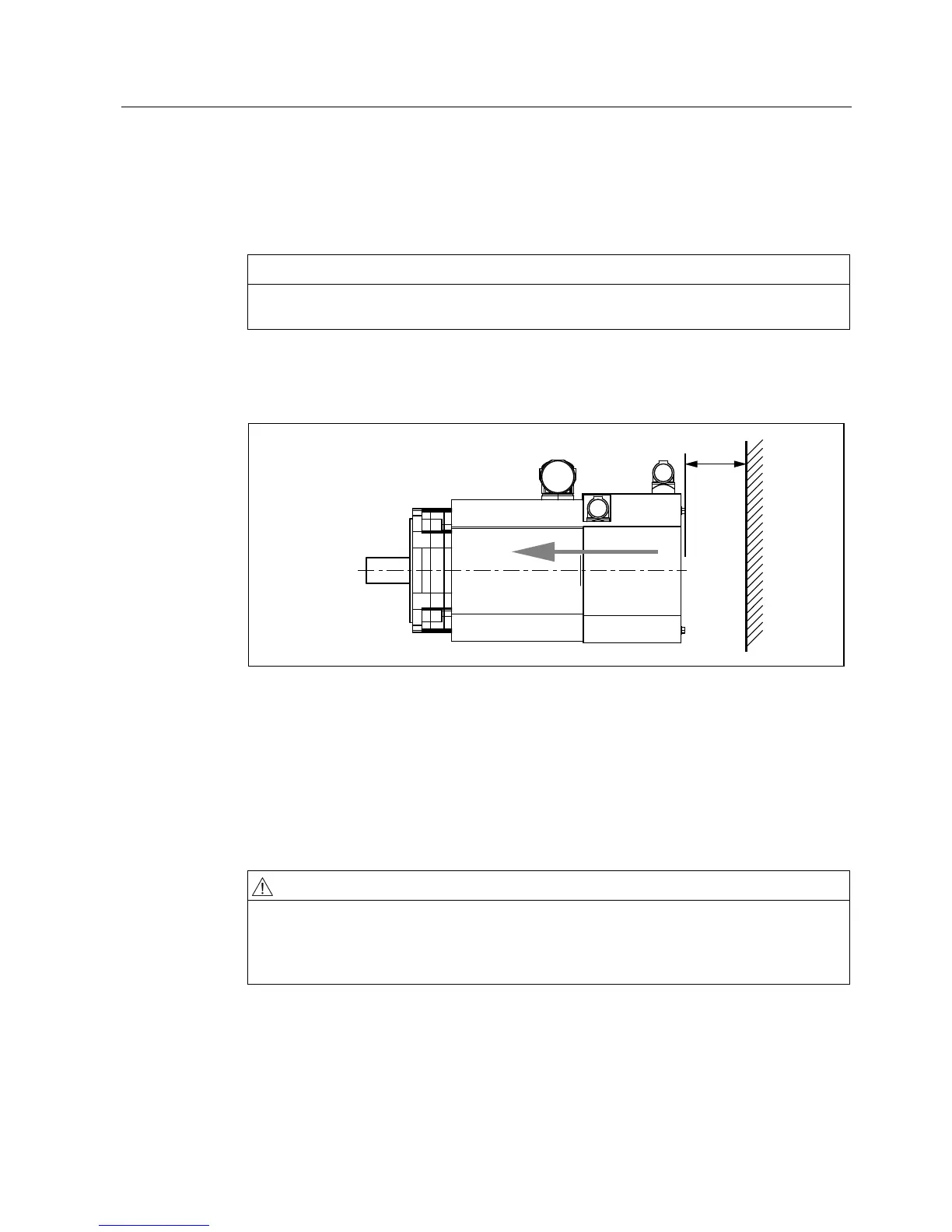

The motors must be arranged in such a way that the cooling air can flow in and out without

obstruction and that the minimum clearance s between the inlet/outlet air openings and

adjacent components is maintained (see "Minimum clearance" diagram below).

V

s A minimum clearance of 30 mm applies for AH 63 and AH 80.

A minimum clearance of 50 mm applies for AH 100.

Figure 3-2 Minimum clearance s

Steps must be taken to ensure that hot outlet air cannot be drawn back into the system. The

direction of air flow is from the non-drive end (NDE) to the drive end (DE). The fan may only

be operated with normal ambient air, as air containing chemical or conductive impurities

could cause the fan to fail prematurely. Deposits from contaminated air could result in poor

heat transfer at the motor or could cause the cooling-air duct to become clogged, leading to

an overheated motor.

WARNING

Danger of being drawn into the machine

There is a danger of being drawn into the machine (by means of hair, ties, loose items, etc.)

at the air inlet. Suitable protective measures must be taken to guard against this: wear a

hairnet, take off ties, keep clear of the intake area, etc.

Loading...

Loading...