7SG15 MicroTAPP Description of Operation

©2013 Siemens Protection Devices Limited Chapter 1 Page 15 of 38

4.8.4 Circulating Current Compensation

The relay will control group transformers in parallel without recourse to a complex Master/Follower scheme. Two

methods can be used: -

1 Reactive current minimisation, an enhanced version of the TAPP patented system as used with the

SuperTAPP range of Siemens Protection Devices Ltd equipment. Using this system, widely recognised for its

operational advantages, transformers can operate in parallel either at a site or across a network thus giving

greater network flexibility.

2 Circulating current control, this method enables transformers to operate in parallel when connected to a

common busbar at a site at any power factor, but NOT across a network or between groups of busbars.

The relay response for each method, when selected, is determined by the transformer characteristics entered into

the set-up menu.

4.8.5 Tap Stagger

The MicroTAPP can still be utilised for the export or import of reactive current (tap stagger). The voltage control

menu is used to set the magnitude of the reactive current and a status input can be set to initiate the tap stagger

process. The value of reactive current is set as a percentage of the transformer group full road rating, i.e. for a

9MVA group a setting of +10% would result in an exported reactive current of 0.9MVAr and a -10% setting would

result in an import of 0.9MVAr.

4.8.6 Time Delays for Operation

When a busbar group voltage is outside upper or lower deadband, the initial corrective tap control output is

delayed by a pre-set time. This time delay is the ‘initial tap time delay’ as described previously and shown in

Figure 2.

Where the voltage is drifting in and out of the deadband, the initial delay time-out is determined by the difference

between the accumulated times that the voltage is outside and inside the deadband. The relay counts up to the

initial tap delay time for the period that the voltage is outside the deadband. If before the initial tap delay time is

reached the voltage returns within the deadband, then the equipment will count down for the period that the

voltage is within the deadband.

In the event of a voltage ‘swing through’ the relay accumulates voltage excursion times from both the lower and

upper deadbands as described above. The first time delay to expire will initiate the appropriate corrective tap

change operation.

If more than one tap change operation is required for correction of a voltage deviation, subsequent tap change

operations are determined by an ‘inter-tap delay’ setting which has a definite time characteristic. The time is

settable from the menu and should normally be slightly longer than the tap changer operating time.

5 Control

The relay provides for both Manual and Automatic control of the tap changing system.

The relay is configurable for either Local control, or Remote control through a communication system from a

control centre. The communication medium may be serial communications or from hard wired contacts.

If manual control is exercised from a point where an indication of the power system voltage is not available the

relay can be arranged to inhibit tap change operations that would drive the system voltage to an abnormal level,

e.g. control at the tap changer mechanism.

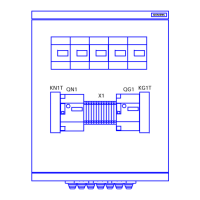

5.1 Control Points

Electrical control of a tap change mechanism is normally exercised from three points: -

5.1.1 At the tap change mechanism

A Local/Remote selector switch at the Tap Changer is connected to the MicroTAPP enable input. When set to

Local, this disables tap change operation from all other control points. When set to Remote, control is enabled

from the MicroTAPP relay.

Loading...

Loading...