7SG15 MicroTAPP Application Guide

9 Wiring Configurations

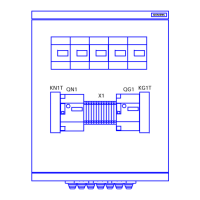

Diagrams located at the end of this section show typical arrangements for tap change control schemes. Inputs to

the relay and outputs for indications and control are user programmable. Tables 5, 6 and 7 give examples of the

I/O allocation for a complete control system as shown in the example scheme with the inclusion of other features

not shown on the diagrams. 11 inputs are used with 5 outputs. Other combinations of I/O are available, see

description of operation.

INPUTS

Terminal Default Allocation

Status 1

MicroTAPP enabled (to allow for control at tap

changer)

Status 2 Lower signal to tap changer

Status 3 Raise signal to tap changer

Status 4 3% voltage reduction from SCADA **

Status 5 6% voltage reduction from SCADA **

Status 6 Prepare for Switch-Out from SCADA **

Status 7 Tap in Progress switch is closed

Status 8 Auto selection from SCADA **

Status 9 Manual selection from SCADA **

Status 10 Raise signal from SCADA **

Status 11 Lower signal from SCADA **

Table 5

Controls can also be carried out by use of the serial communication connections into the relay making use of the

inputs marked ** unnecessary.

OUTPUTS

Terminal Default Allocation

Relay 1 Prepare for Switch-Out complete

Relay 2

Use N/C for Tap Changer motor supply

contactor reset

Relay 2

Use N/O for Tap Changer motor supply

latched contactor trip

Relay 3 Voltage control fault alarm

Relay 4 MicroTAPP initiated Lower signal

Relay 5 MicroTAPP initiated Raise signal

Table 6

OTHER INPUTS

B9,11,13,15,17,19 (B23 is

common)

Digital TPI

B23,25,27 Resistor TPI

Table 7

©2011 Siemens Protection Devices Limited Chapter 5 Page 14 of 21

Loading...

Loading...