7SR224 Argus Commissioning & Maintenance Guide

©2010 Siemens Protection Devices Limited Chapter 6 Page 22 of 73

1

1

General Starter

51-n

51c-n Setting

51c-n Charact

51c-n Time Mult

51c-n Follower DTL

c

51c-n Reset

Cold Load

Enabled

L1 Dir En

L2 Dir En

L3 Dir En

Disabled

c

start

trip

c

start

trip

c

start

trip

51c-n Min. Operate Time

Reduced

Current

Enabled

Disabled

51c-n Delay (DTL)

CB Open

CB Closed

Pick-up Time

Drop-off Time

Reduced Current DTL

Reduced

Current Level

c

<

<

<

IL1

IL2

IL3

51c

See Delayed

Overcurrent

(51-n)

1

&

S

R

Q

&

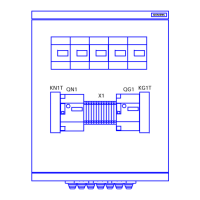

Figure 2-5 Cold Load Logic diagram

Ensure that the Cold load active is not raised. This can be reset by CB closed for more than the Cold Load Drop-

off Time or current less than the Reduced Current Level for greater than the Reduced Current Time. Check the

Cold Load Pick-up Delay by applying or simulating CB Open. Measure the time delay before Cold Load Active is

raised. Apply current above the Reduced Current Level if this functionality is Enabled before applying CB Closed.

Measure the time for Cold Load Active to reset.

2.4.1 Inverse Time Overcurrent (51C)

It will be advantageous to map the function being tested to temporarily drive the relevant Pickup output in the

Pickup Config sub-menu in the Output Config menu as this will allow the Pick-up led to operate for the function.

Gradually increase current until Pickup LED operates.

Apply 2x setting current and record operating time,

Apply 5x setting current and record operating time.

Compare to calculated values for operating times

Operate Current Operate Time

Ph. Dir Char.

(NI EI VI

LTI, DTL)

Is

(A)

TM

P.U.

(Amps)

D.O.

(Amps)

2 x Is

(sec)

5 x Is

(sec)

NOTES

I

L1

(I

A

)

I

L2

(I

B

)

P.U.

D.O.

&

TIMING

TESTS

I

L3

(I

C

)

Loading...

Loading...