Installation

64/214 Revision 11 • INSTALLATION AND OPERATING INSTRUCTIONS • 8DA10 • 861-9601.9

➭ Clear the assembly opening ② : Remove all horizontal flange covers on the busbar

housing ① of the fixed-mounted panel.

➭ Undo the busbar ⑤ at the joint ③ in the busbar housing through the assembly opening ② .

The busbar support ⑩ remains in the disassembled busbar section.

➭ Take the busbar section ⑤ with the busbar support ⑩ out of the housing through the

vertical flange ④ .

➭ Through the vertical flange ⑨ , push the busbar section ⑤ into the busbar housing ⑦ of

the panel to be lined up

➭ Clean the links at the busbar sections using an emery sponge and a lint-free cloth.

Then, apply a very thin film of the supplied mounting paste.

➭ Assemble the busbar section at the joint ⑧ .

➭ Check alignment and parallel position of the assembled busbar section,

and correct if required.

Special configurations of the interconnected busbar

Preparing the flanges of the busbar housings

➭ Clean all vertical flanges of the busbar housings at the panel joint and the grooves for

the toroidal sealing rings (O rings) carefully with lint-free paper.

➭ Carefully check the sealing surfaces ③ of the flanges for scratches, other damages or

pollution. Damages and pollution will cause leaks.

➭ If the sealing surfaces ③ are damaged: Inform the regional Siemens representative and

coordinate the elimination of damages.

➭ Grease the toroidal sealing rings ② uniformly with the supplied mounting paste

(Polylub GLY 801).

➭ Apply a layer of mounting paste (Polylub GLY 801) with a thickness of approx. 3 mm all

around on the external contact surfaces of the flanges.

➭ Distribute the mounting paste (Polylub GLY 801) evenly on the external contact surfaces ①

with a fine line brush.

➭ Lay the toroidal sealing rings (O-rings) into the grooves of the flanges.

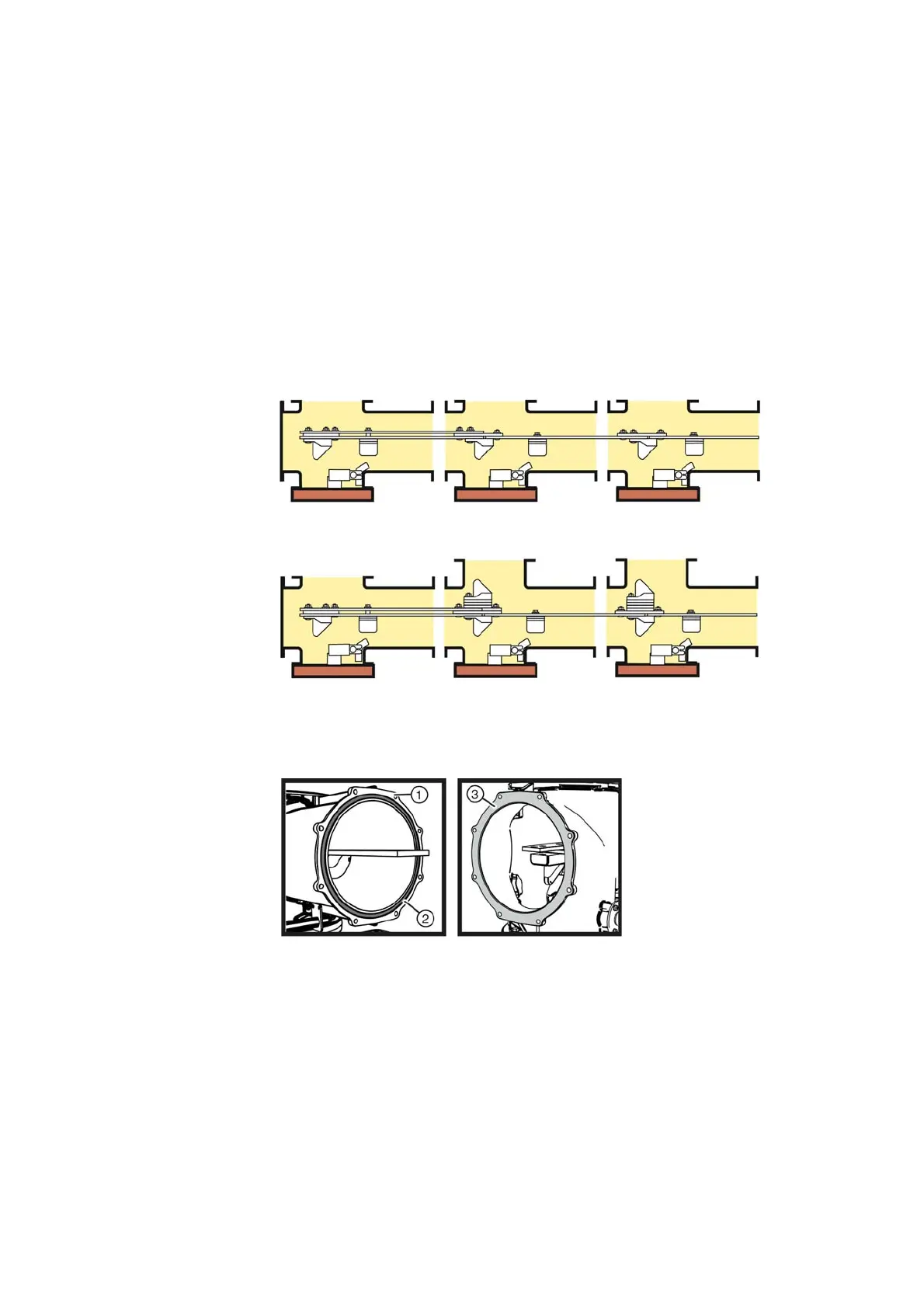

Fig. 44: Busbar assembly, left end panel (example: 1250 A)

Fig. 45: Busbar assembly, left end panel, adjacent panels with disconnectable busbar

components (example: 1250 A)

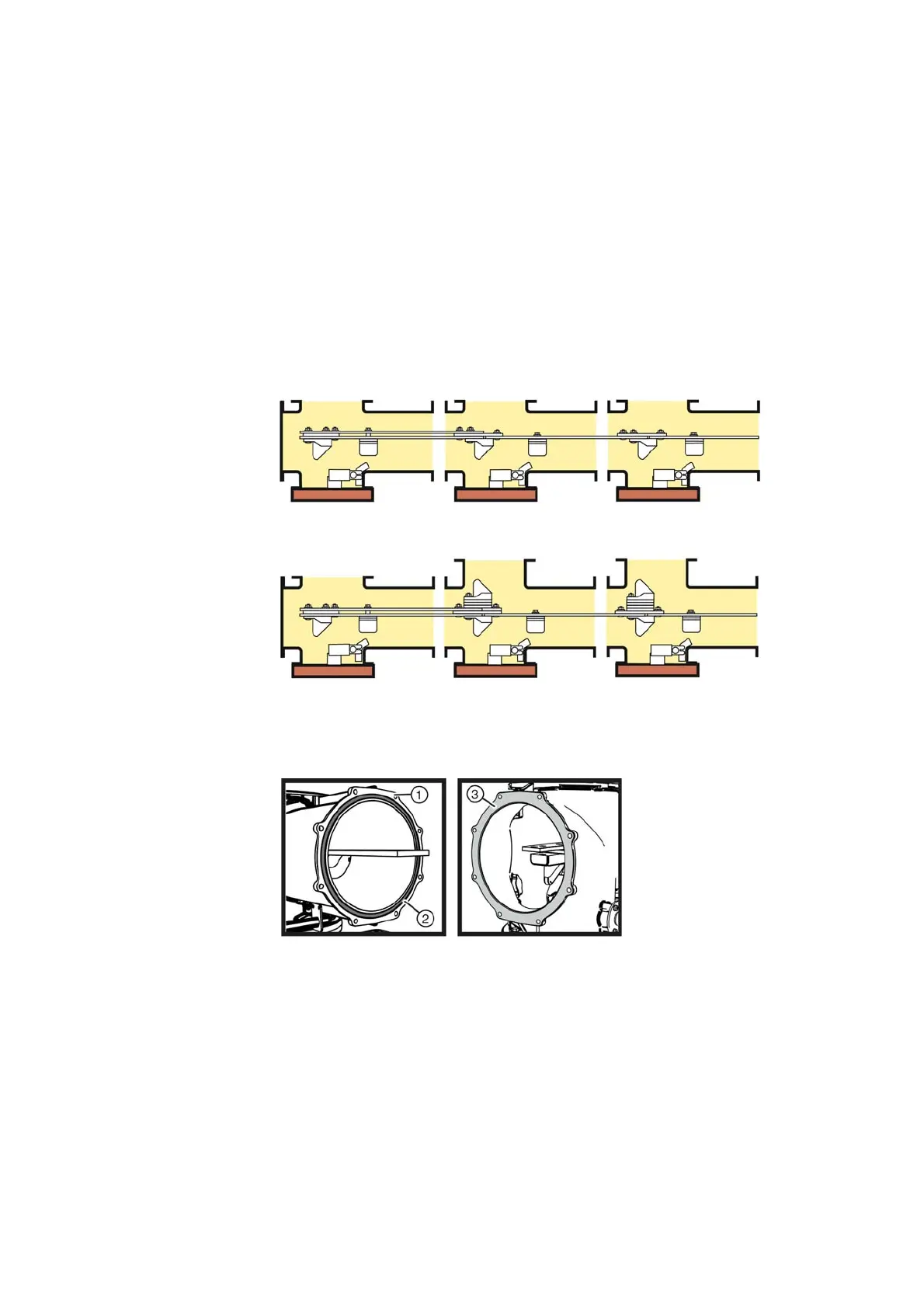

Fig. 46: Flange on the busbar housing

①

External contact surface of

the flange

②

Groove for toroidal sealing ring

③

Sealing surface at

the opposite flange

Loading...

Loading...