861-9601.9 • INSTALLATION AND OPERATING INSTRUCTIONS • 8DA10 • Revision 11 89/214

Installation

Mounting

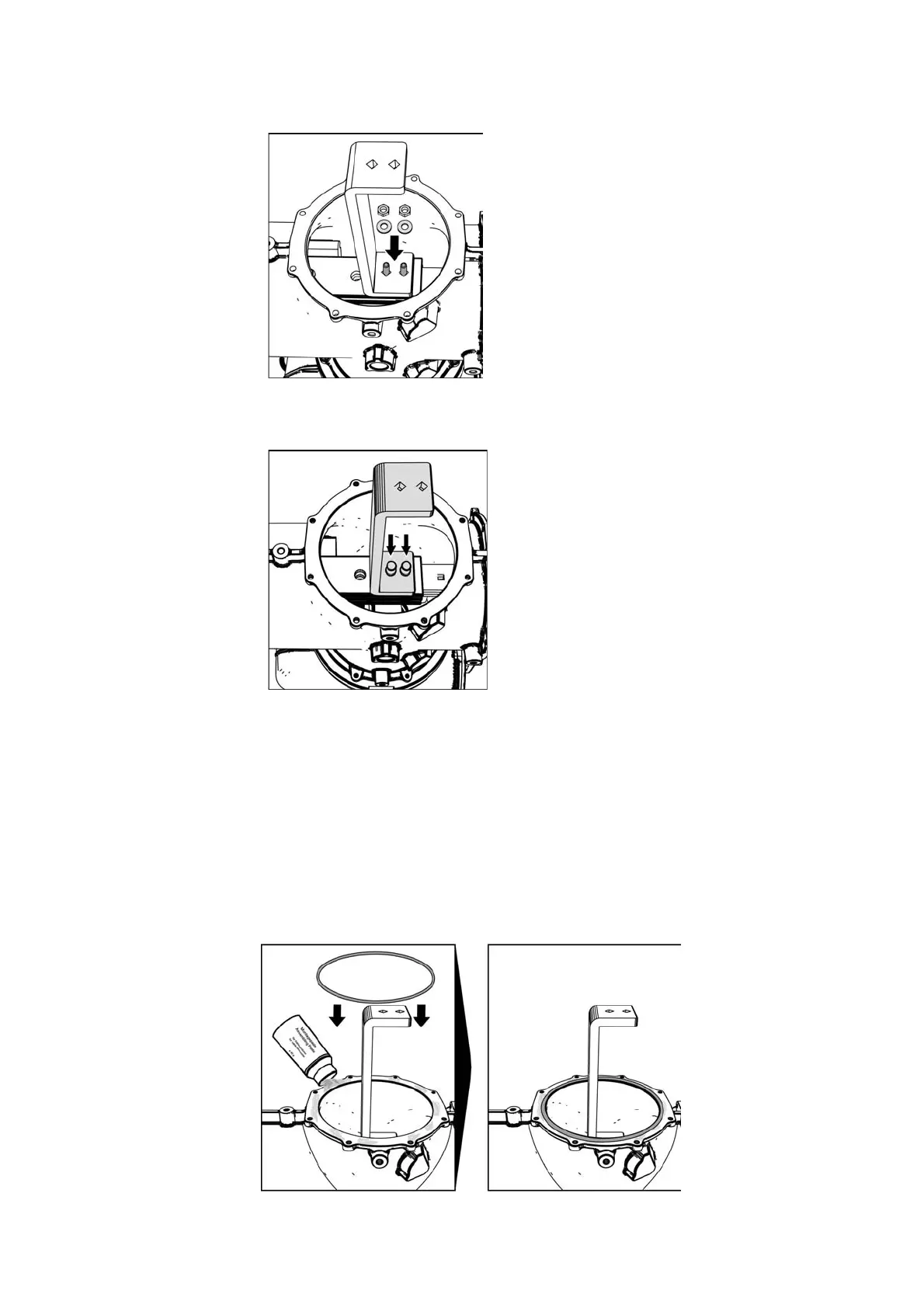

the supporting angle

➭ Undo the hexagon nuts at the busbar and mount the supporting angle.

Tightening torque: 40 Nm.

Fig. 94: Fixing the supporting angle

➭ Fit supporting angles for the complete panel, and fit protective caps on the bolted joints.

Fig. 95: Fitting protective caps

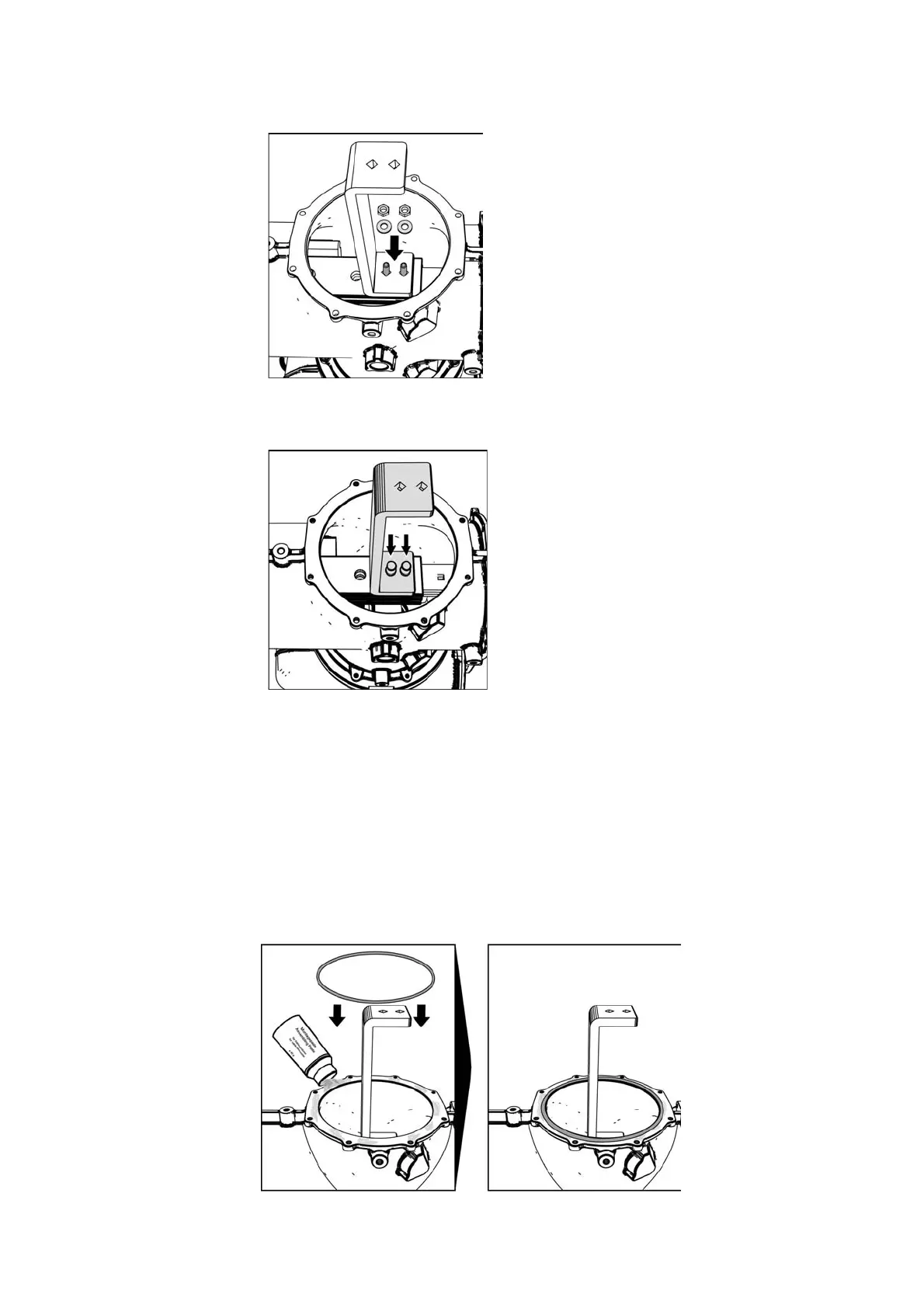

Cleaning and greasing

the flanges

➭ Clean all horizontal flanges of the busbar housings and the grooves for the sealing rings

carefully with lint-free paper.

➭ Carefully check the external contact surfaces of the flanges and the grooves for scratches

and other damages or pollution. Damages and pollution will cause leaks.

➭ If any external contact surfaces or grooves are damaged: Inform the regional Siemens

representative and coordinate the elimination of damages.

➭ Apply a uniform film of the supplied mounting paste to the flanges and O-rings (sealing

rings). To do this, apply a grease strip of approx. 3 mm thickness on the external contact

surface of the flanges. Use the supplied Polylub GLY 801 mounting paste only.

➭ Lay the O-rings into the grooves of the flanges.

Fig. 96: Greasing and inserting the sealing ring

Loading...

Loading...