4.3 Designing the pipe system

Take the following into account for an effective design:

● Pipe length

● Number of aspirating holes

● End cap hole

● Number and radius of bends

● Number of pipes

● Length of capillary tubes

● Size of bends and branches

● Differences in air pressure

● How the total airflow is split into separate airflows for each pipe

● Equalization of airflows in the pipes

● Response time, i.e., the time it takes to transport air to the aspirating smoke

detector from aspirating holes that are far away

● Sensitivity of the aspirating holes

● Total power of the system including all components

● End caps with holes at the end of the pipes are used to adjust the airflow

● Filter box and its effect on the airflow (must be taken into account in the

software 'FXS2056 ASD Asyst‑Tool V3')

● The air return pipe must be kept as short as possible so as not to impair the

aspirator.

4.4 Planning the pipe system

w You are familiar with the function of the aspirating smoke detector and the local

conditions.

◈

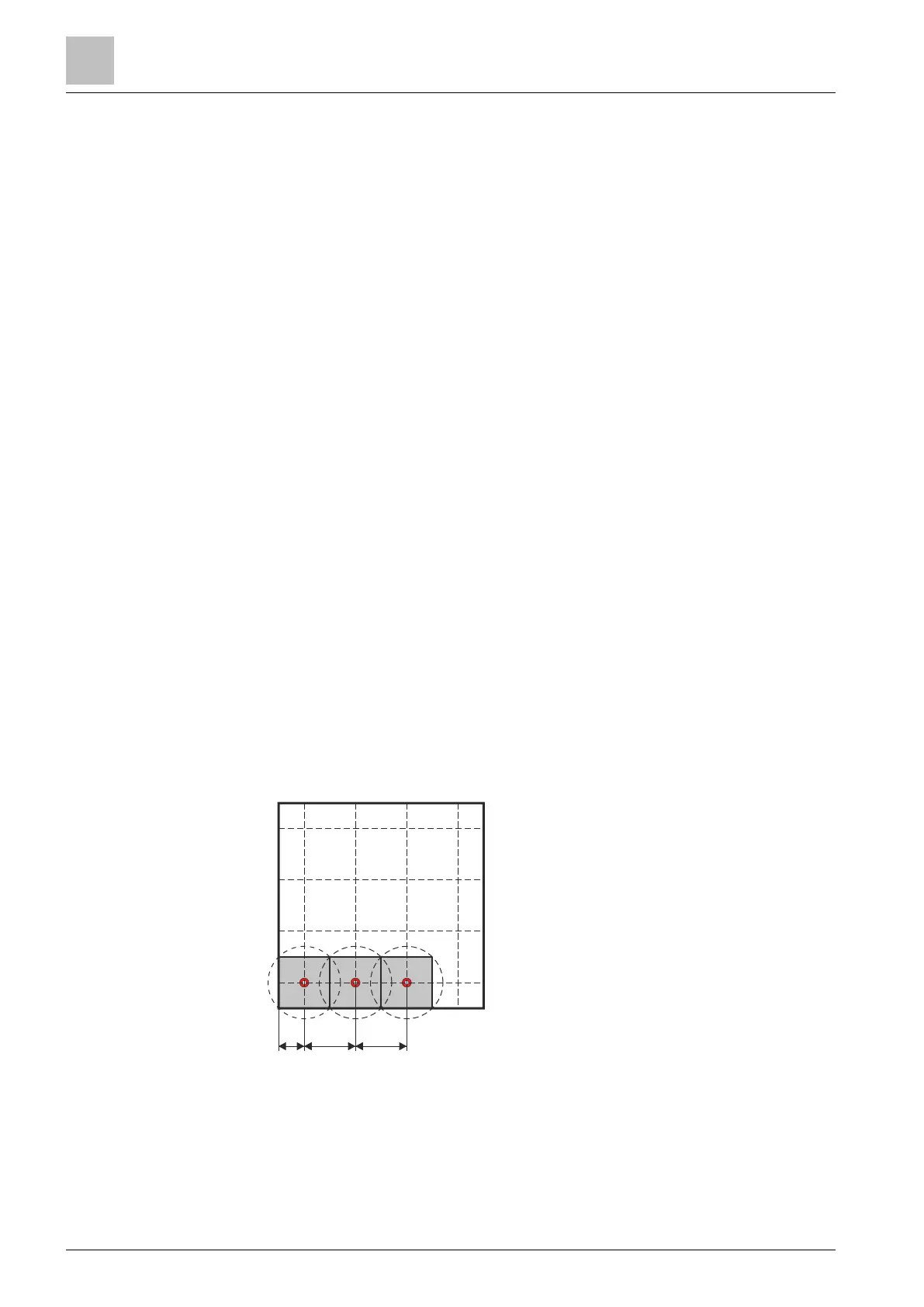

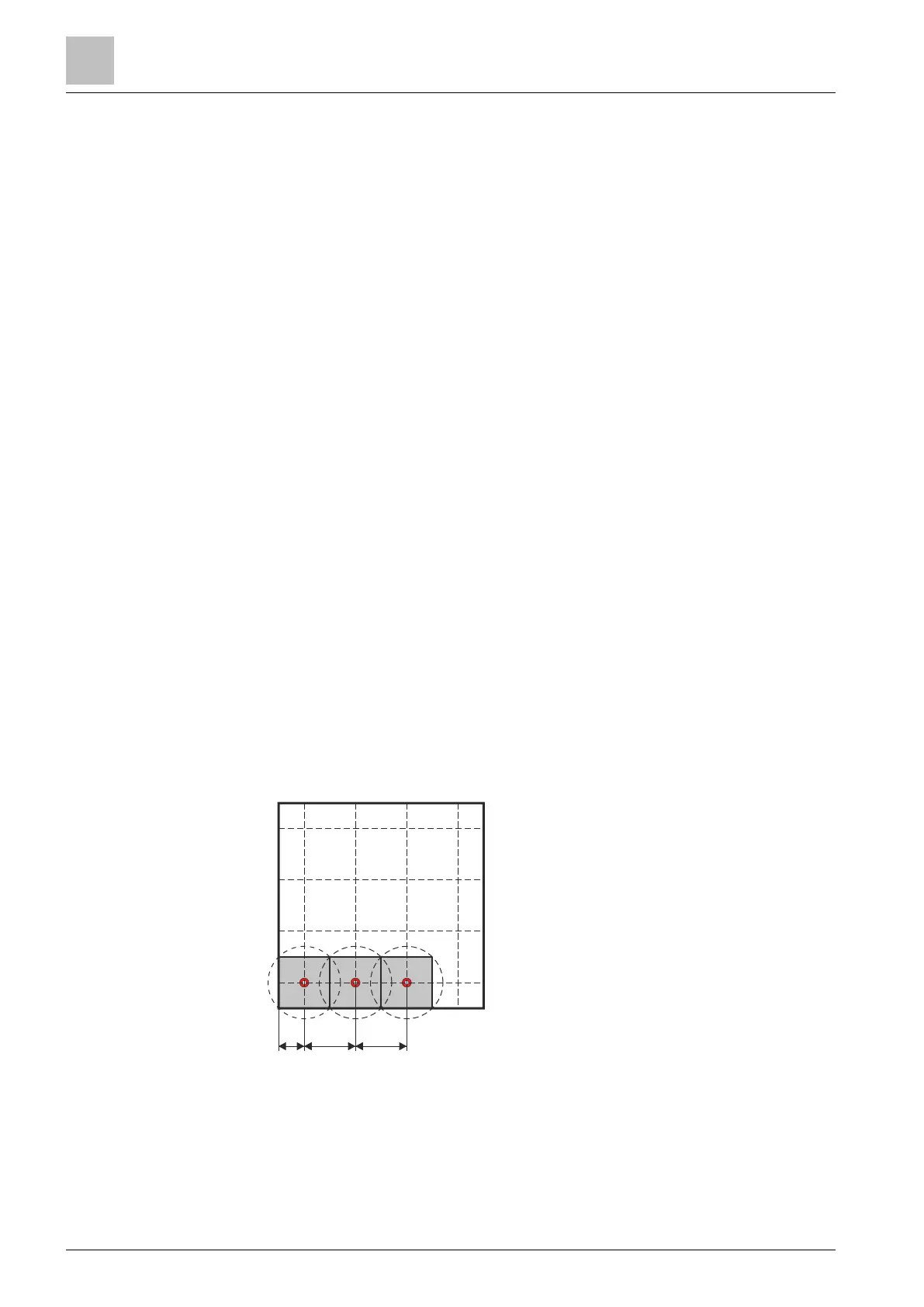

Spread the aspirating holes throughout the room like the nodes in a network.

– Typical mesh sizes are 3x3m, 4x4m, and 6x6m.

– The maximum gap(A) from the wall to the nearest aspirating hole is

defined in local regulations and guidelines.

– The maximum gap(B) between two aspirating holes is 10m.

Fig. 11: Planning the pipe system

a The network of aspirating holes has been created.

Planning

Designing the pipe system

4

28 | 48 A6V11783979_en--_a

Loading...

Loading...