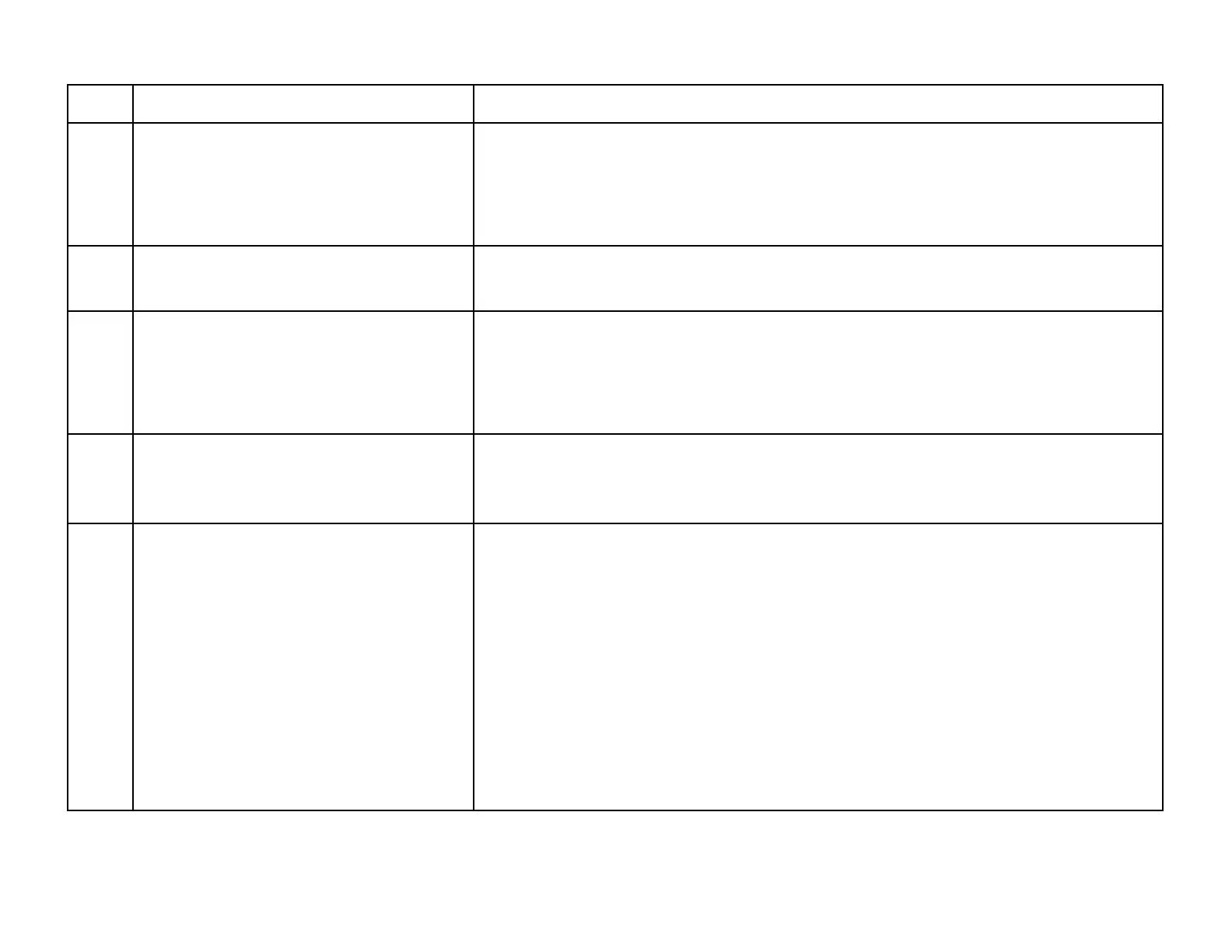

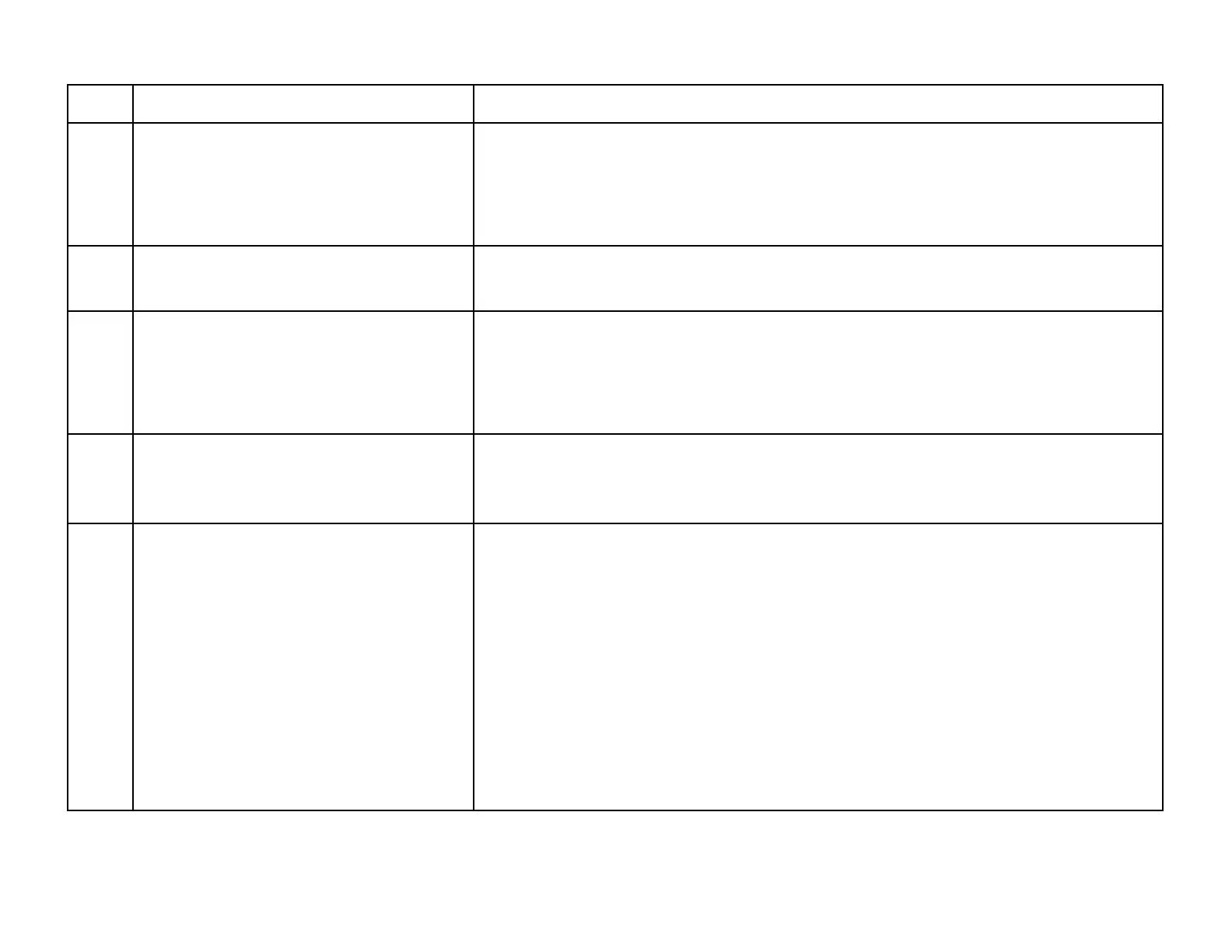

Complete Fault Code List

Description of the Fault Corrective Action

2 No flame at start-up

A flame failure occurred during lightoff.

1. Check the wiring of the ignition transformer, pilot valve, and main valve(s).

2. Ensure manual shutoff valves on the pilot gas line and main gas line are open.

3. Check the fuel / air ratio at lightoff.

4. Check the flame detector signal in the presence of a known flame source. Replace the flame detector if it

does not produce the anticipated signal.

3 Air pressure switch open

The air pressure switch connected to terminal X3-02.1 is open, causing a fault. Ensure the setpoint of the

switch is set to an appropriate value. Check the wiring of the air pressure switch. If no air pressure switch is

being used, place a jumper from terminal X2-01.3 to X3-02.1.

4 Extraneous light

An extraneous light (flame signal present when there should be none) fault occurred.

1. Ensure that the source of light is not a flame. If it is, take corrective action immediately.

2. Ambient light can cause an extraneous light fault. Ensure the flame scanner is viewing a dark area.

3. UV scanners typically fail on, giving a false flame signal. Remove UV scanner and cover the bulb to

ensure it is not seeing any light. Look inside the bulb and see if any purple arcs of electricity are occurring

between the electrodes in the bulb. If there are, replace the UV scanner.

5 Air pressure switch closed

The air pressure switch connected to terminal X3-02.1 is closed before the blower output is energized in

phase 22, causing a fault. Ensure the setpoint of the switch is set to an appropriate value. Check the wiring

of the air pressure switch. If no air pressure switch is being used, place a jumper from terminal X2-01.3 to

X3-02.1.

6 Actuator position fault

The required position feedback from the connected SQM… actuator was not received.

1. Ensure the potentiometer on the SQM… actuator is wired correctly.

-For counter-clockwise actuators (SQM40…, SQM50…), terminal "c" on the potentiometer should be wired

to terminal X66.1 on the LME7, and terminal "a" on the potentiometer should be wired to terminal X66.3 on

the LME7.

-For clockwise actuators (SQM41..., SQM50...R), terminal "a" on the potentiometer should be wired to

terminal X66.1 on the LME7, and terminal "c" on the potentiometer should be wired to terminal X66.3 on

the LME7.

2. Ensure the SQM... actuator is wired properly to the LME7, especially the position feedback on terminal

X2-09.4 of the LME7.

3. Ensure no mechanical stops are preventing the actuator from reaching its expected position.

4. While not common, heavy vibration on the actuator can wear a track in the position feedback

potentiometer. If the fault always occurs at the same actuator position, the actuator may need to be

replaced, and the vibration needs to be reduced to avoid having a similar issue with the new actuator.

Section 7 Page 3 SCC Inc.

Loading...

Loading...