Image processing

3.2 Code verification

SIMATIC MV500

Operating Instructions, 05/2019, C79000-G8976-C494-02

43

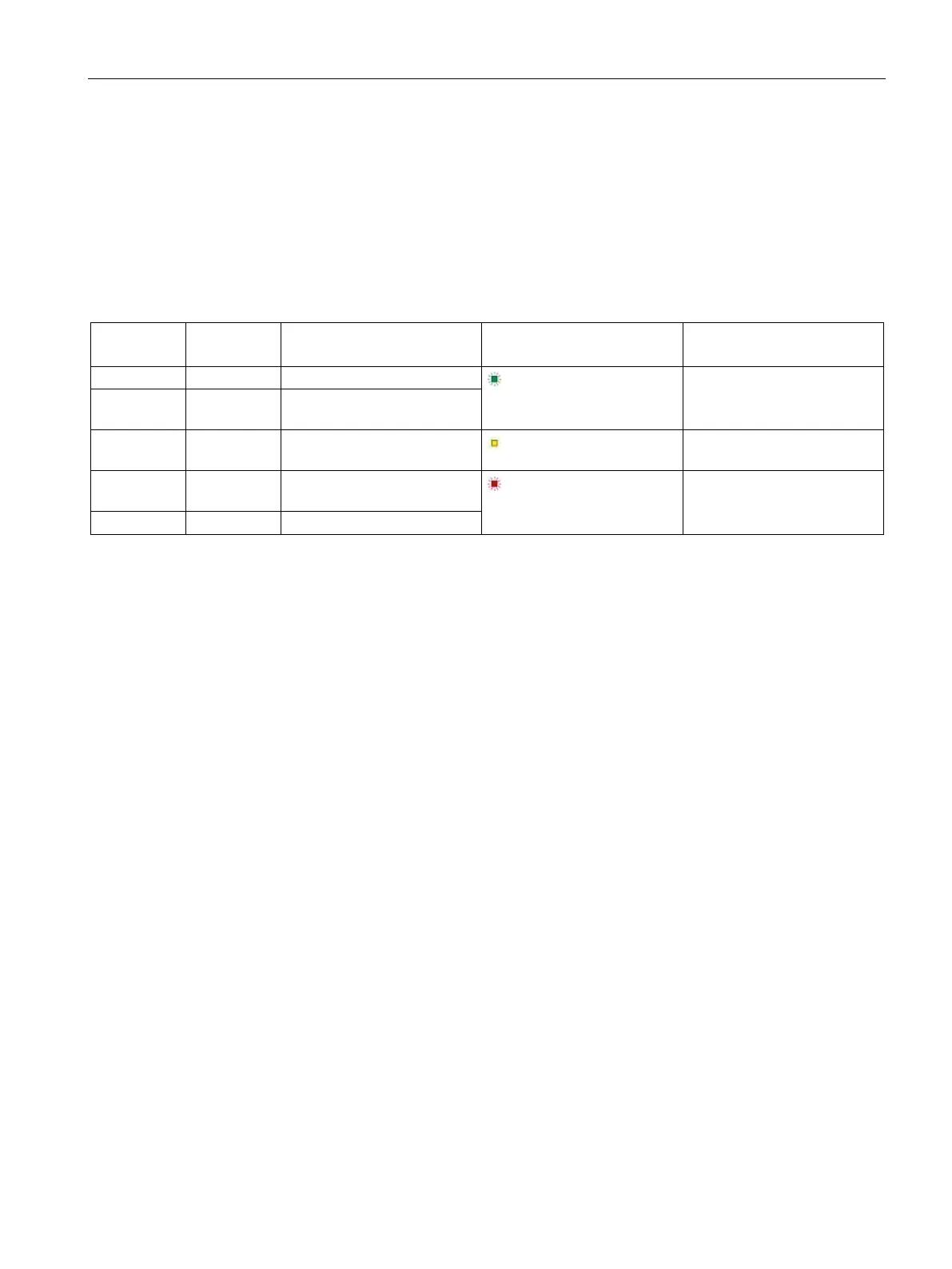

Evaluation

The classification is specified in the WBM as a value from 4 to 0 (or A to F without E). In

addition, each quality grade is assigned one of three ratings (good [G] / fair [F] / poor [P]).

This classification not only allows fast visual checks of the quality using the color coding of

the display, but also automatic rejection of the read result as "N_OK" if it falls below a certain

quality threshold.

Table 3- 1 Quality levels

Defaults for quality grading

Representation in the user

interface

Defaults for the read result

Green = [G]ood OK

3 B Can be set specifically by

user

1)

2 C Can be set specifically by

1)

Yellow = [F]air OK

1 D Can be set specifically by

1)

Red = [P]oor N_OK

(Can be set for specific us-

ers)

1)

The user-specific setting is only for ascending or descending order.

Example

In an application in which only very good markings are acceptable, all grades below 4 are set

to "Poor". This allows the rejection of all unacceptable specimens.

3.2.3 Verification of printed labels

In 1996, the "Association for Automatic Identification and Mobility" (AIM) published the data

matrix symbology specification with an evaluation procedure for print quality. According to

this evaluation procedure, test systems could evaluate a symbol according to its degree of

acceptability (4 to 0).

The specification later became the ISO/IEC 16022 standard. This type of test was developed

for paper labels with high contrast.

It allows a quantitative measurement of the print quality and allows the testing of printed 2D

codes based on a quality standard. Here, the important fact is that the printing of a data

matrix code on paper is a high-quality process.

White paper is printed with black ink to achieve a high contrast. With this background, the

threshold values for grading in the ISO/IEC 16022 standard are very restrictive because the

marking quality is so high.

Less exacting requirements are neither suitable nor useful in the printing industry. The AIM

standard identifies the following typical errors:

● Blocked ink jets

● Too much or too little ink

Loading...

Loading...