9.3.6 Maintenance intervals

Please note the following in order to identify faults at an early stage, rectify them and avoid

follow-on damage:

• Maintain the machine regularly and carefully.

• Inspect the machine.

• Motors must be allocated a revision/inspection number after inspection.

NOTICE

Motor failure

Material damage can occur if the machine develops faults or is overloaded.

• Immediately inspect the machine if faults occur.

• An immediate inspection is especially necessary, if the three-phase motor is excessively

stressed, either electrically or mechanically (e.g. overload or short-circuit).

The machines are equipped with permanently lubricated rolling bearings. The machine may

be equipped with a regreasing device.

CAUTION

Skin irritations and eye inammations

Many greases can cause skin irritations and eye inammations.

• Follow all safety instructions of the manufacturer.

Measures, intervals and deadlines

Measures after operating period intervals or deadlines have elapsed:

Operating situations and characteristics can vary widely. For this reason, only general

maintenance intervals are specied here. Maintenance intervals should therefore be

scheduled to suit the local conditions (dirt, starting frequency, load, etc.).

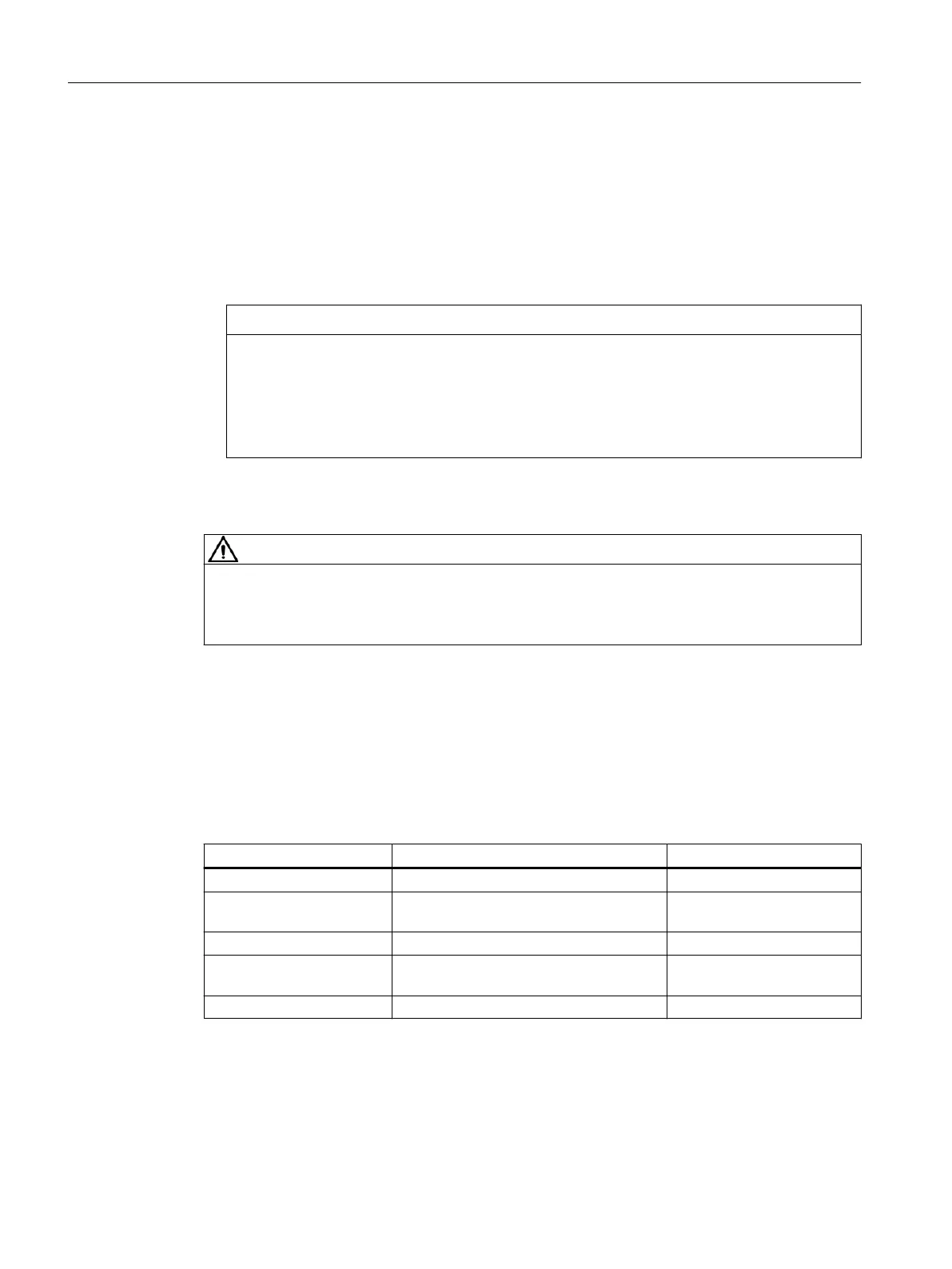

Table 9-3 Operating period intervals

Measures Operating period intervals Intervals

Initial inspection After 500 operating hours After 1/2 year at the latest

Relubrication (optional) Refer to the lubrication plate or the rating

plate

Clean Depending on the degree of pollution

Main inspection Approximately every 16000 operating

hours

After two years at the latest

Drain condensate Depending on the climatic conditions

Maintenance

9.3Inspection and maintenance

1LE5, 1PC4 shaft heights 280 ... 355

102 Operating Instructions, 11/2022, A5E41454666A

Loading...

Loading...