Detailed description

2.1 NC/PLC interface signals

Basic logic functions: Various NC/PLC interface signals and functions (A2)

14 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

DB31, ... DBX1.3 == 1 (axis- / spindle disable).

The traversing request is maintained. If the axis disable is cancelled when a traversing

request is pending DB31, ... DBX1.3 = 0 the movement is carried out.

Axis disable when machine axis in motion

When machine axis is in motion and NC/PLC interface signal DB31, ... DBX1.3 == 1 the

movement of the machine axis is decelerated to a standstill via the axis-specific brake

characteristics currently active or, if it is part of an interpolated path movement or coupling, it

is decelerated on a path or coupling-specific basis.

The movement is continued if the axis disable is canceled by another pending traversing

request: DB31, ... DBX1.3 = 0.

Spindle disable

The response is determined by the current spindle mode:

• Control mode: Speed setpoint = 0

• Positioning mode: See above "Axis disable".

DB31, ... DBX1.4 (follow-up mode)

"Follow-up mode" is only effective in conjunction with the NC/PLC interface signal:

DB31, ... DBX2.1 (servo enable)

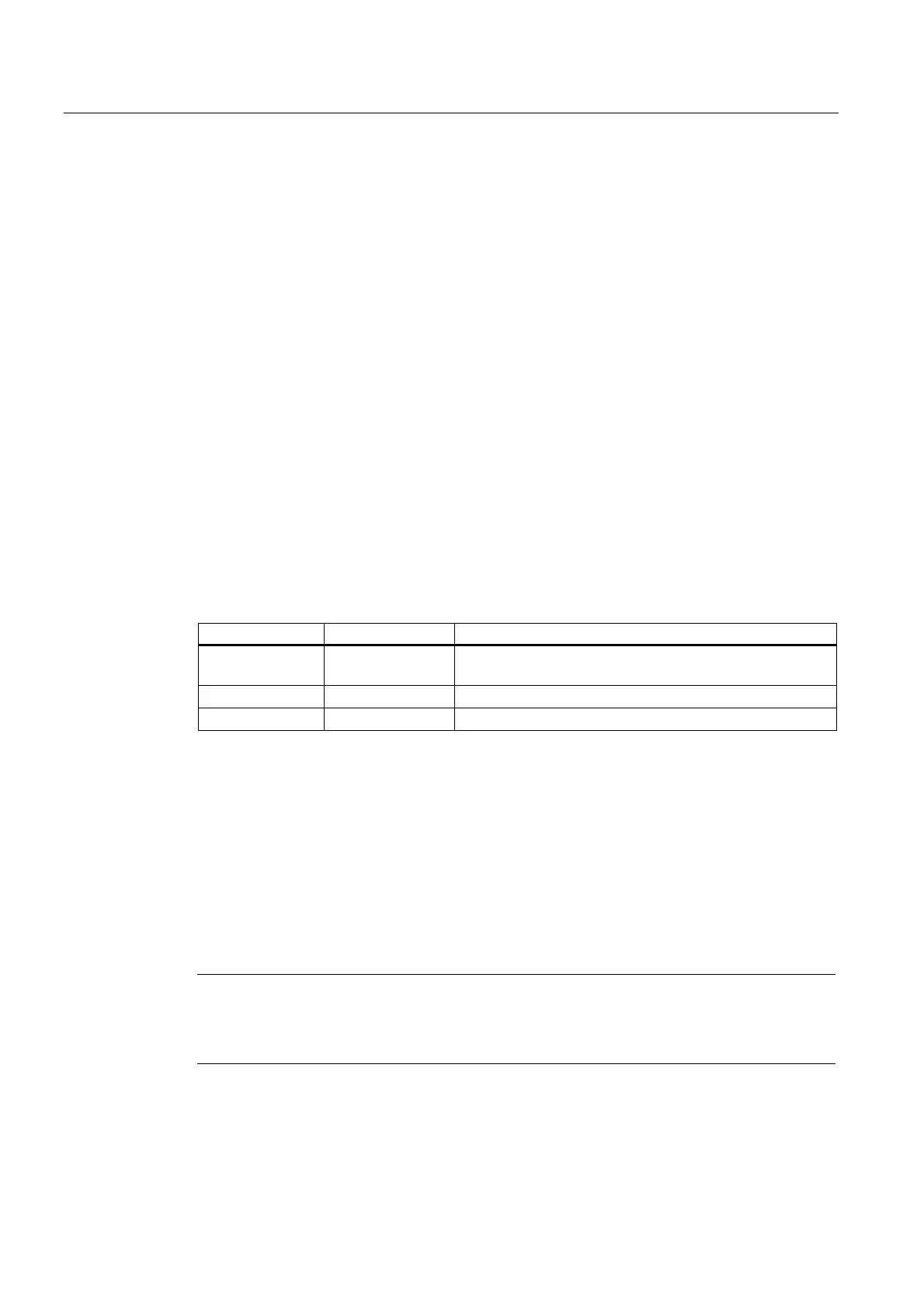

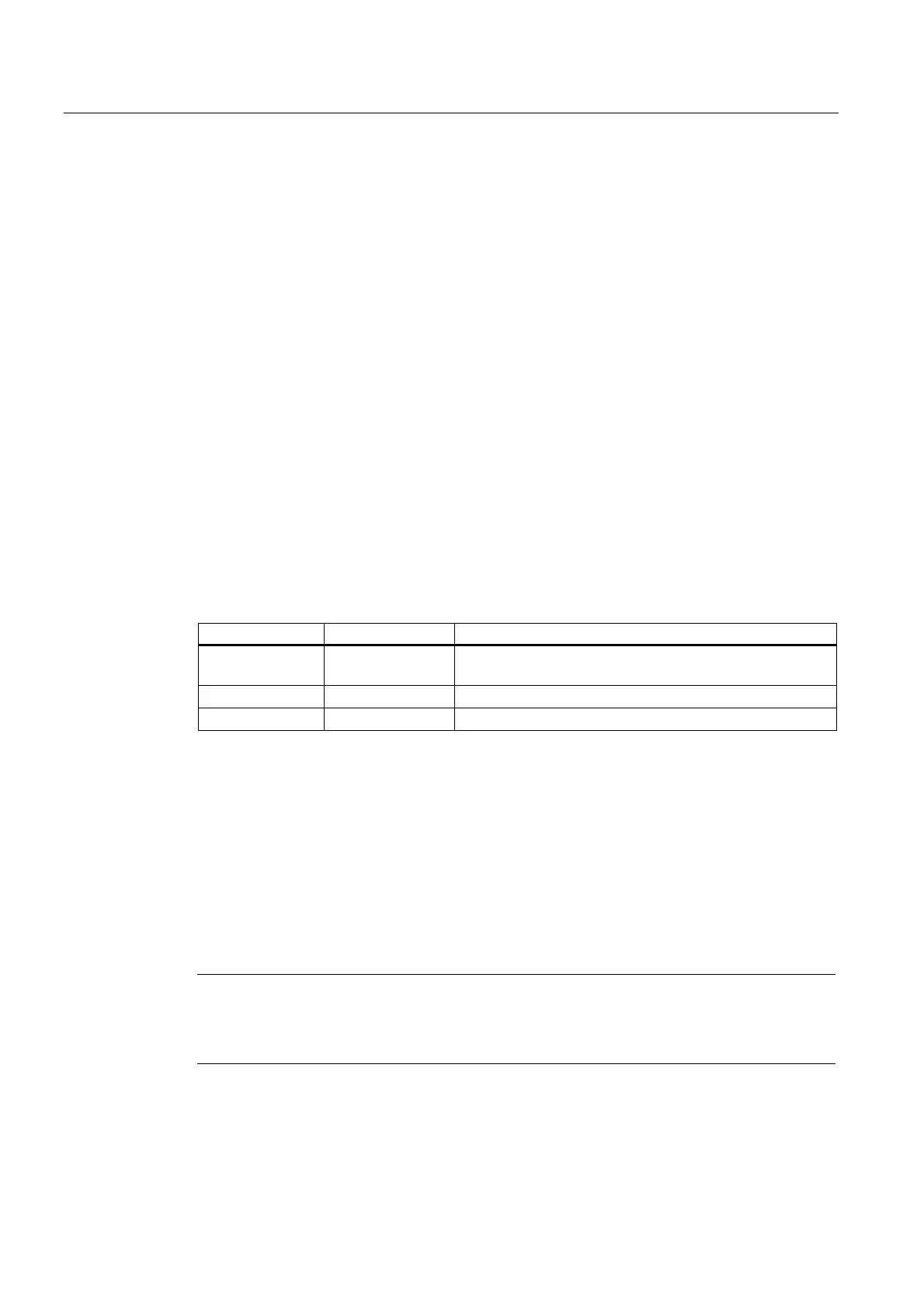

DB31, ... DBX2.1 DB31, ... DBX1.4 Function

1 Ineffective Normal operation (machine axis in closed-loop control

mode)

0 1 Followup

0 0 Hold

Function: Follow-up

During follow-up, the setpoint position of the machine axis is continuously corrected to the

actual position (setpoint position = actual position).

The following interface signals have to be set for the follow-up function:

DB31, ... DBX2.1 = 0 (servo enable)

DB31, ... DBX1.4 == 1 (tracking mode)

Feedback:

DB31, ... DBX61.3 = 1 (follow-up mode active)

Note

When the servo enable is set from follow-up mode, if the part program is active, the last

programmed position is approached again internally in the NC (REPOSA: Approach along line

on all axes). In all other cases, all subsequent movements start at the current actual position.

During "follow-up", clamping or zero-speed monitoring are not active.

Loading...

Loading...