Basic information

1.4

© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

14

1.4 Surface quality, accuracy, speed

Special attention must be paid to the CAD -> CAM -> (post processor) -> CNC process chain

when machining three-dimensional geometries, e.g. free-form surfaces. CAM systems generate

NC programs for free-form surface machining. The CAM system receives the workpiece geome-

try from a CAD system. The CNC machine has to process the NC data generated and convert it

into axis movements.

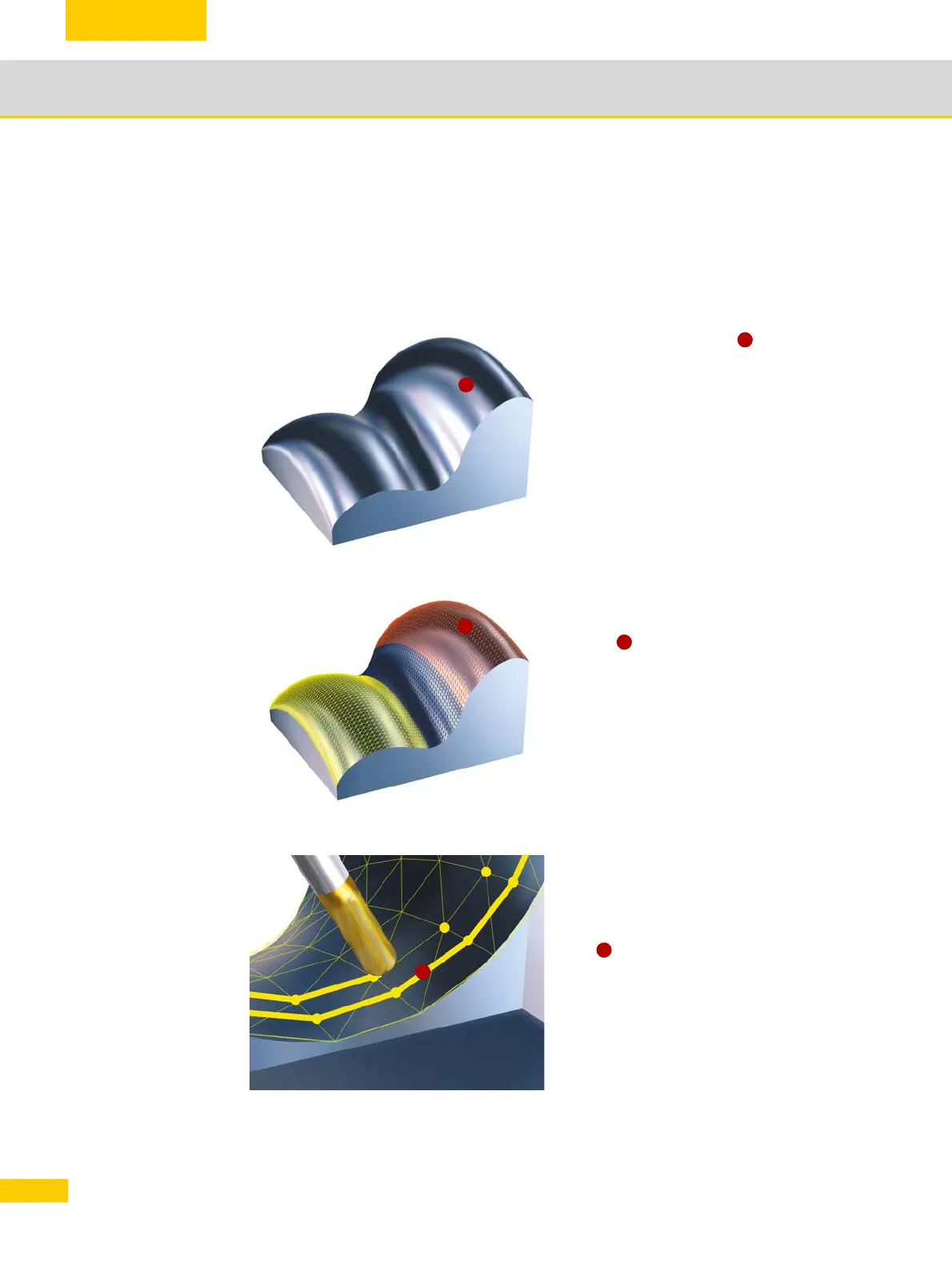

In CAD systems, surfaces of higher orders

are constructed (free-form surfaces).

For example, in order to be able to mill an

entire surface - or for collision checking - the

CAM system generally converts the CAD free-

form surface into a polyhedron.

This means that the smooth design surface is

approximated by a number of individual small

planes .

This produces deviations from the original

free-form surface.

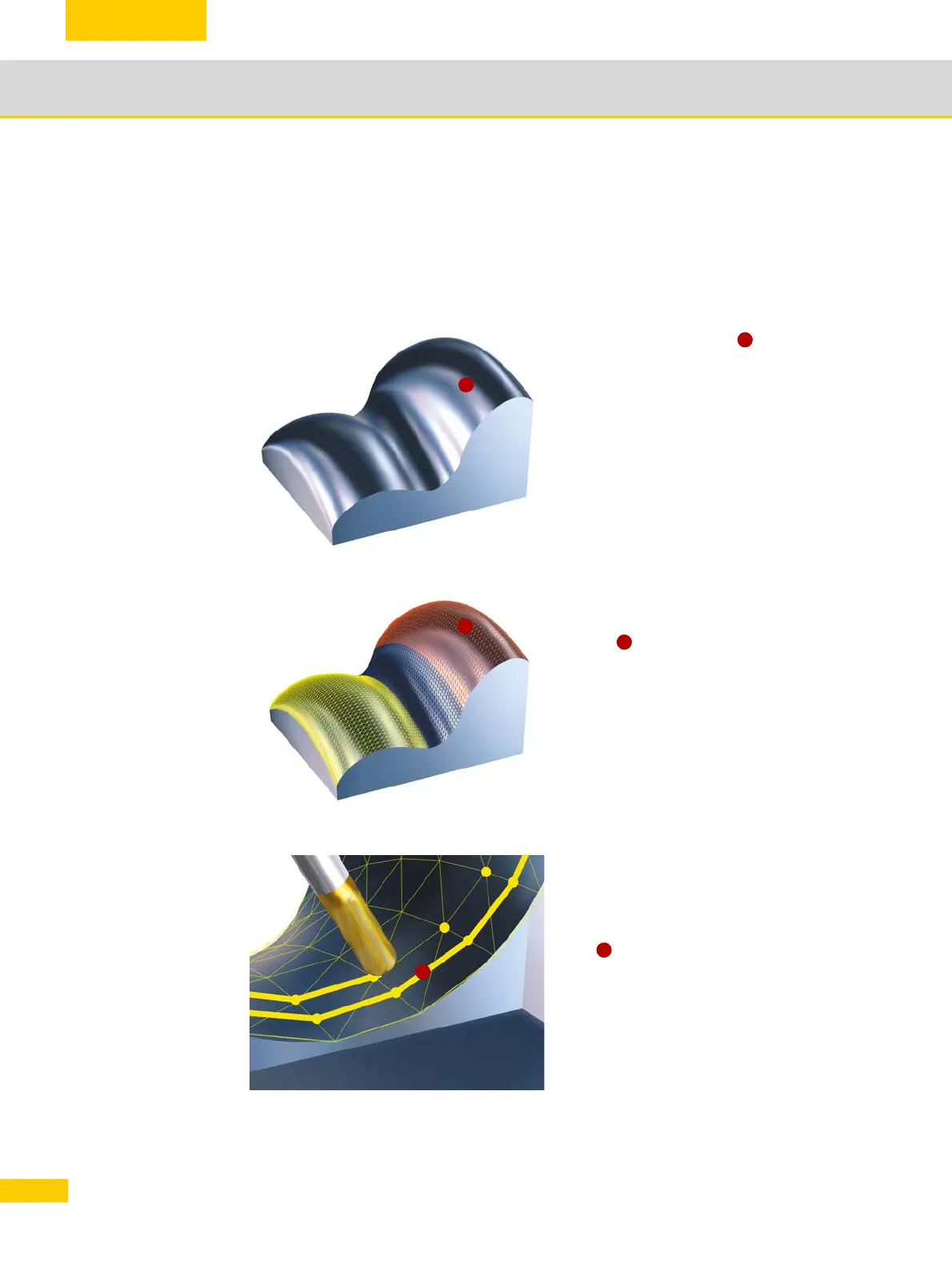

The CAM programmer overlays this polyhe-

dron with tool paths. From these, the post pro-

cessor generates NC blocks within the

specified error tolerances. These usually com-

prise many short straight line elements, G1 X

Y Z.

Thus, the machining result is no longer a free-

form surface, but a polyhedron. The small

planes of the polyhedron can be visibly

mapped on the surface.

This can result in undesirable remachining.

1

1

2

2

3

1

G1

G1

G1

G1

3

Loading...

Loading...