General information on workpiece production

2.7

© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

30

2.7 Measure workpiece in AUTOMATIC

With in-process measurements in Automatic mode, NC programs are specifically parameterized

for the measuring task (measuring cycles). The input screens of the program editor are used for

parameter assignment. The measuring points to be approached and the measuring task are

automatically implemented in accordance with the measuring program.

For measuring tasks that are repeated, e.g. setup for multi-part machining, you can simply run

the NC programs and the workpieces will be measured plus aligned, and the tools corrected

automatically.

The workpiece is measured to determine workpiece tolerances in the production process.

Depending on the measuring cycle used, you can select the following options as the result of

workpiece measurement:

Measurement only without offsets (actual value is measured)

Work offset compensation (setpoint - actual value deviation)

Tool data offset (setpoint - actual value deviation)

2.7.1 Measuring cycles in AUTOMATIC for SINUMERIK

Practical measuring cycles are provided to facilitate in-process measurements.

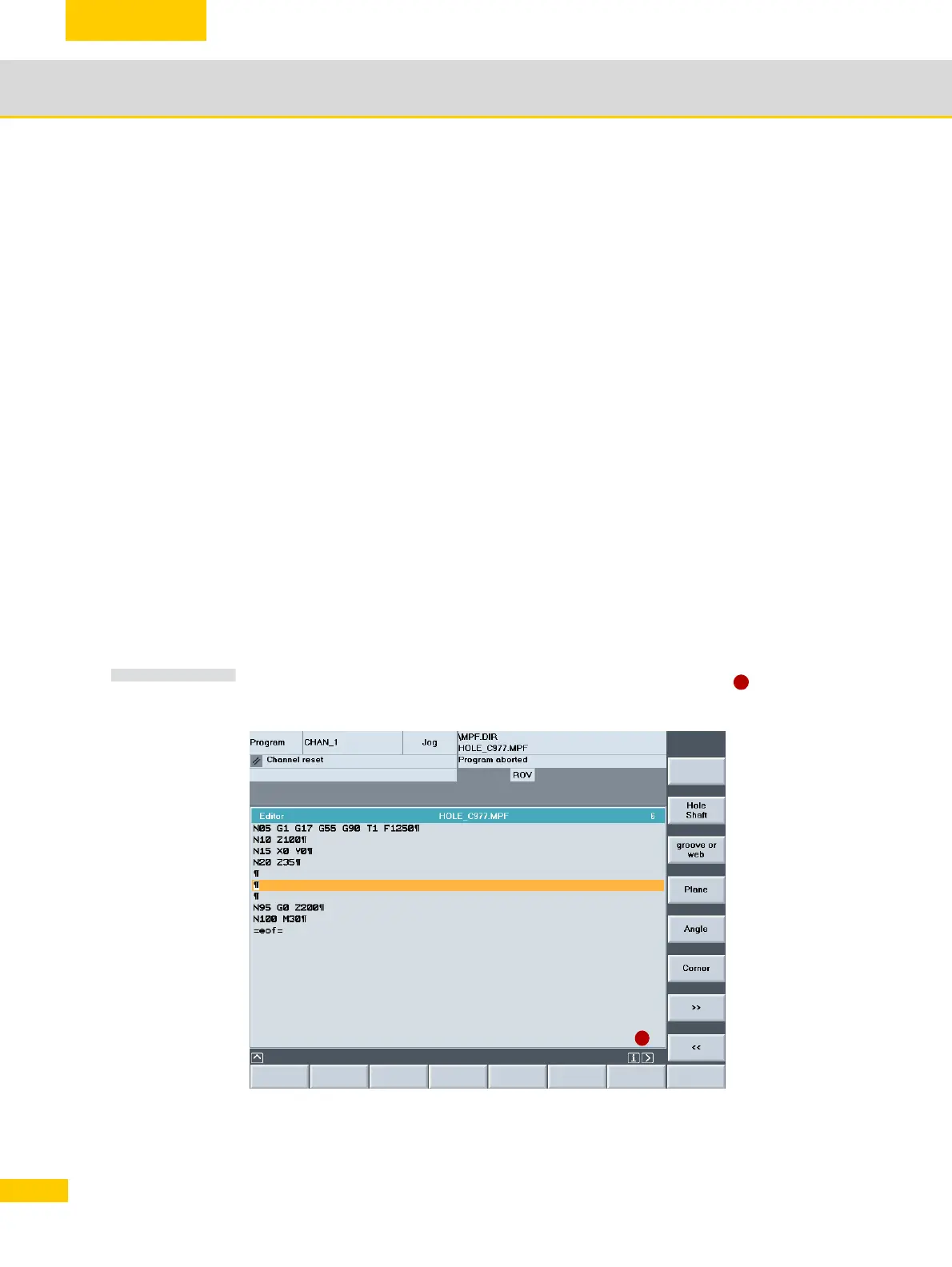

X You can select the measuring cycles within the NC program using the softkeys Measure Mill

> Measure workpiece.

The softkeys for in-process measurements can be found on the expanded softkey bar.

You can switch to this softkey bar by pressing the expansion arrow > ( )

Measuring cycles

in AUTOMATIC

NOTE

1

→ Measure hole/shaft

→ Measure groove/web

→ Measure surface

→ Measure angle

→ Measure corner

→ Continue to Measure sphere

and rectangle

→ Back

1

Loading...

Loading...