General information on workpiece production

2.1

© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

18

2.1 Process chain for producing 5-axis workpieces

The production process chain generally starts with workpiece design. The data generated at this

stage provides the basis for further processing and, ultimately, for production.

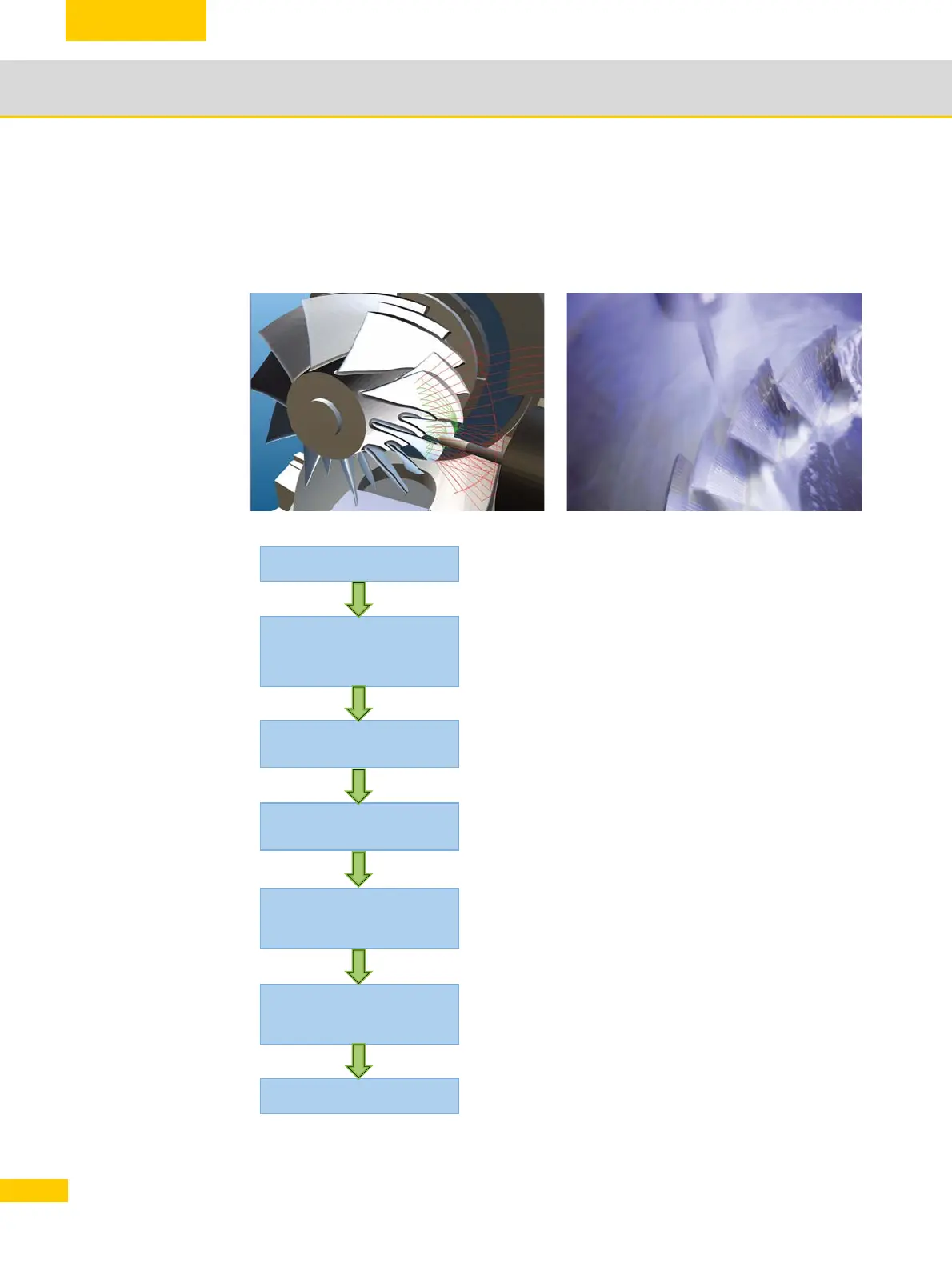

CAD/CAM Production

CAD model

CAM strategies

Calculation of

tool paths

Simulation of

tool paths

Post processor

Setting up the machine

Quality

Machining

Generating a CAD model

Using the CAM system's internal strategies and methods

to generate the individual machining steps and to

calculate the paths.

Simulation of the calculated tool paths with collision

checking.

Generation of the NC code in the post processor.

Generally, it is the path at the tool tip (TCP) that is

output in the NC code.

Data transmission of NC programs and setting up of tool

and workpiece. Possible creation of a main program that

will call the generated geometry programs.

Definition of the high speed settings, e.g. in CYCLE832, if

not already taken into account by the post processor.

These consist of the following: tolerance, compressor,

continuous-path control, smoothing, jerk and speed.

Production of workpiece on the machine.

Loading...

Loading...