© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

General information on workpiece production

2.3

21

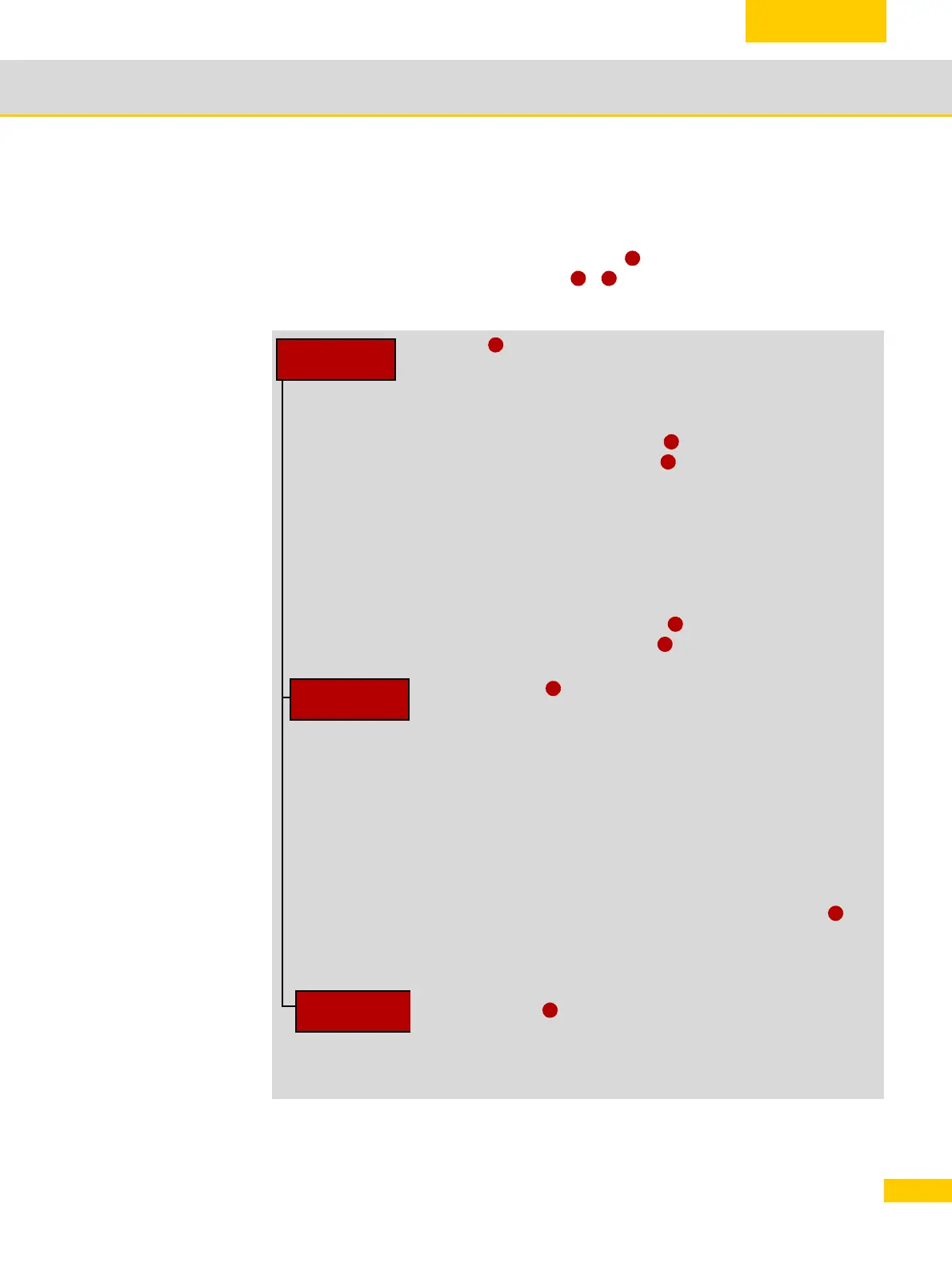

2.3 Program structure for 5-axis machining

Recommendation for a practical program structure with CYCLE832

For machining purposes, a main program is generated that includes all technology data. The

main program calls one or more subprograms , that contain the workpiece's geometry

data. The tool change defines how the content is divided into subprograms.

Example

1

2 3

Call.MPF

N10

N20

N30

N40

N50

N60

T1 D1

M6

M3 S15000

G54

CYCLE832 (0.05,112103)

EXTCALL "CAM_Rough"

; Tool change

; High-speed settings

; All programs should

; be located in one

; directory. If this is not

; the case, then the

; paths must be

; specified.

N70

N80

N90

N100

N110

N120

T2 D1

M6

M3 S20000

CYCLE832 (0.005,112101)

EXTCALL "CAM_Finish"

M30

; Tool change

CAM_Rough.SPF

N1

N2

N3

N4

N17

...

N5046

N5047

...

N5051

...

N6582

N6583

N6584

G90

G0 X0 Y0 Z10

G1 Z0 F500

G1 X-1.45345 Y0.67878 F10000

G1 X-1.81412 Y0.84245

G1 X-4.11845 Y-11.44212

G0 Z10

G1 Z-2.13247 A3=0.34202 B3=0 C3=0.93969 F5000

G1 X7.60978 Y3.55541 A3=0.34202 B3=-0 C3=0.93969

G0 Z50 A3=0.34202 B3=-0 C3=0.93969

M17

CAM_Finish.SPF

N1

N2

....

N7854

G90

G0 X0 Y0 Z10 A3= B3= C3=

.......

M17

Main program

Subprogram

Subprogram

1

4

5

4

5

2

6

3

Loading...

Loading...