© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

General information on workpiece production

2.6

27

2.6 Measure tool in JOG

When executing a program, the various tool geometries must be taken into account. These are

stored as tool offset data in the tool list. When the tool is called, the control considers the tool off-

set data.

You can determine the tool offset data (i.e. the length and radius or diameter) manually, semi-

automatically, or automatically in JOG mode using a dynamometer.

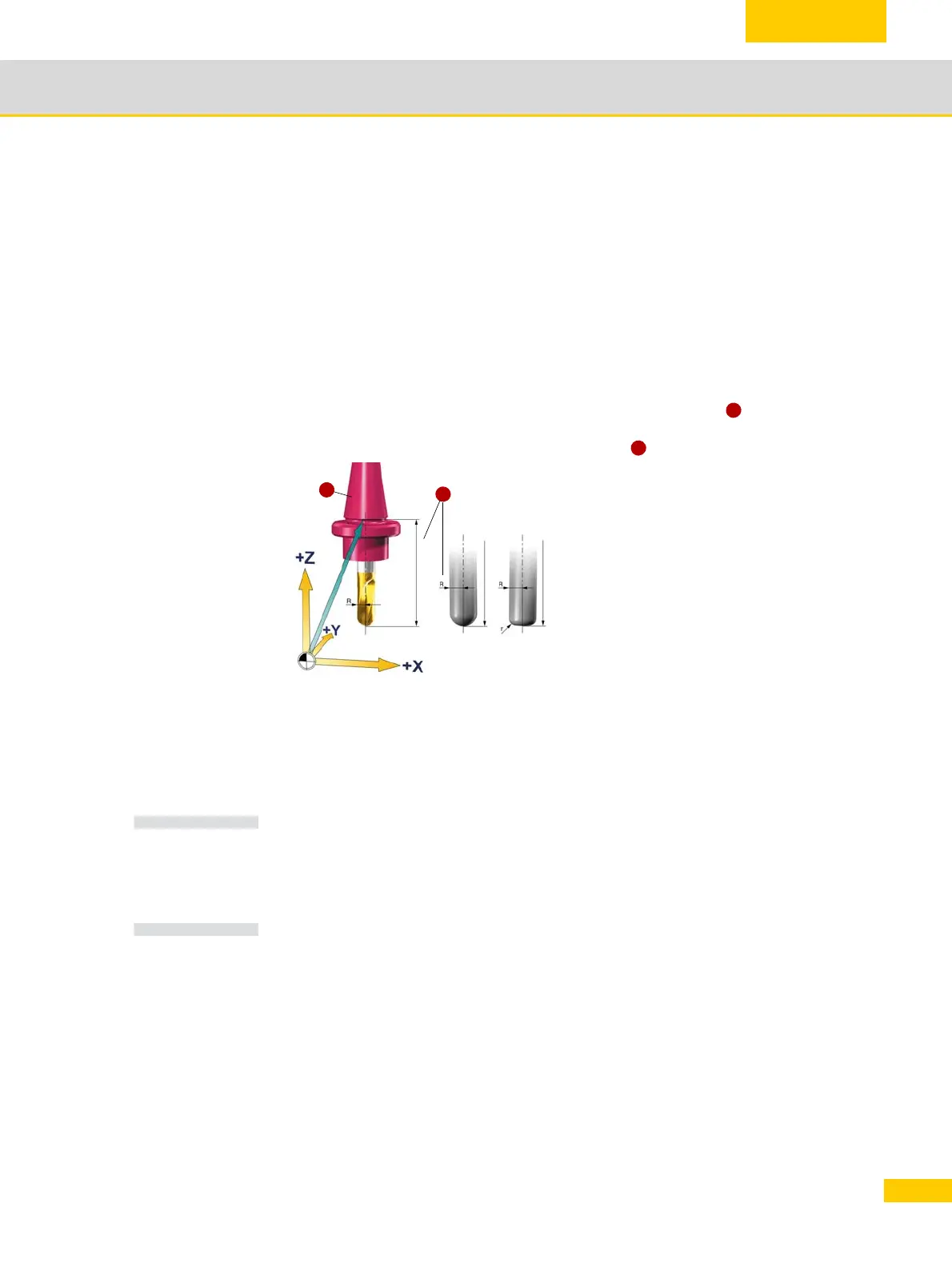

2.6.1 Tool reference point

CAM systems define the position of the TCP differently depending on the tool shape. For

Siemens controls, it is assumed that the TCP is at the tool tip. If the CAM system specifies

a different TCP position then this difference must be taken into account when specifying

the tool length.

Coordinate the following with the CAM programmer: To avoid significant tool deflection,

the CAM programmer should keep the tool length as short as possible.

The tool magazine is loaded as usual, tool

numbers T1, T2 etc. are entered into the

tool table and the tools are assigned a tool off-

set D consisting of radius "R" and length

"L1".

The CAM system already takes into account

the tool diameter when the geometry program

is being created. The calculated tool path

refers to the miller center point (center point

path).

This means that to measure the length of the

tool, you must use the same reference point

(TCP) as the CAM system. For the purpose of

determining the tool length, always remember

to check the reference point the CAM pro-

grammer used to measure L1. The TCP can

either be located at the tool tip or further

upwards in the milling tool - e.g. for radius end

mills at the center of the radius.

1

TCP = Tool Center Point

TCP TCP TCP

T1

L1

L1 L1

Taper base

2

1

2

NOTE

NOTE

Loading...

Loading...