Key functions for 5-axis machining

3.3

© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

42

3.3 Transforming coordinate systems - Frames

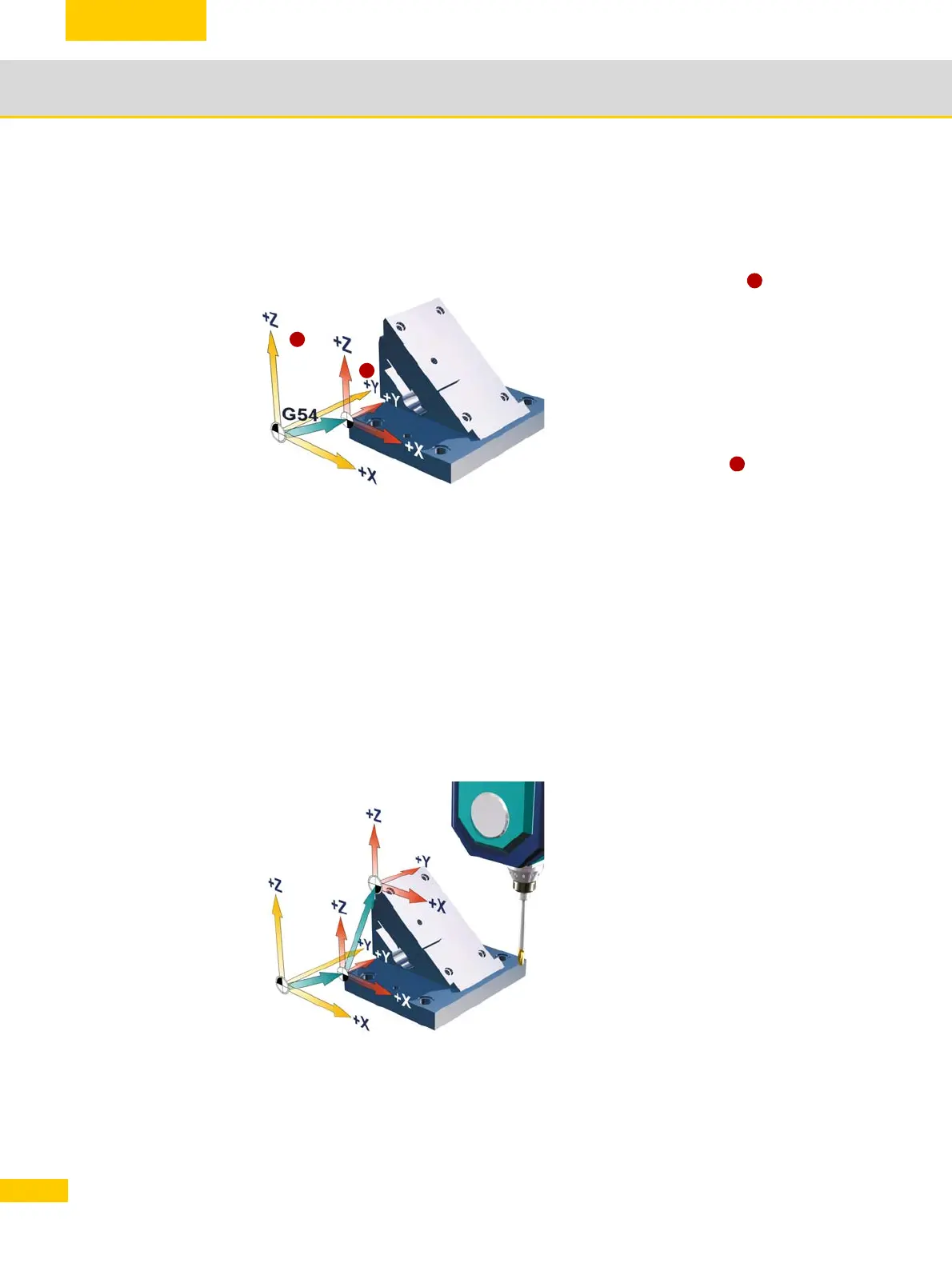

Coordinate systems

Coordinate systems and traversing motion

Machine coordinate system with reference

point and work offset (G54, G55, etc.) are

familiar terms.

Using frames, the coordinate systems can be

shifted, rotated, mirrored and scaled so that

they are aligned with the workpiece surface.

This allows the programming time and costs to

be reduced to a minimum.

With frames, starting from the current work-

piece coordinate system , the position of a

target coordinate system is defined by specify-

ing coordinates and angles.

Possible frames include

Basic frame (basic offset, G500)

Settable frames (G54, G55, etc.)

Programmable frames (TRANS, ROT,

etc.)

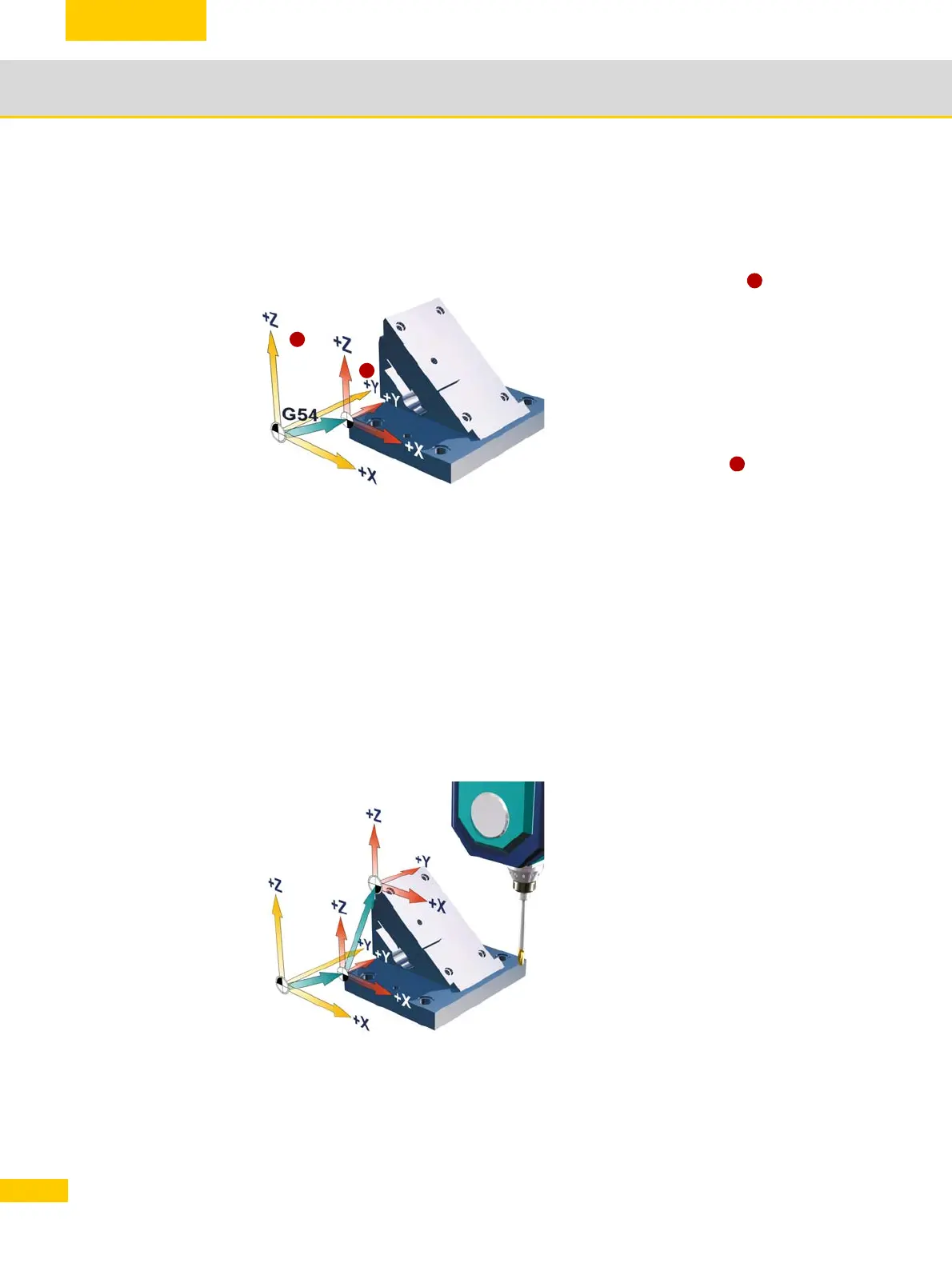

With a 5-axis machine, it is possible to

machine surfaces that can be shifted and

rotated in space as required.

The workpiece coordinate system merely has

to be shifted using frames and then rotated

into an inclined plane.

This is precisely why we need FRAMES. All

subsequent traversing commands now relate

to the new workpiece coordinate system

shifted using frames.

1

2

1

2

Loading...

Loading...