© Siemens AG All rights reserved. SINUMERIK, Manual, 5-axis machining

General information on workpiece production

2.9

35

2.9 Checking/calibrating the machine with the kinemat-

ics measuring cycle CYCLE996

The requirements associated with 5-axis machining can only be met by means of high-precision

machines. As regards kinematic transformation, this means that the vectors for NC-controlled or

manually alignable rotary axes must be determined and entered into the control. CYCLE996 is a

special measuring cycle that has been designed specifically for this purpose. It uses a calibration

sphere and a calibrated probe to measure the rotary axis vectors automatically. In practical appli-

cations, the cycle makes control easier and improves the quality of the process, as compensa-

tions of the rotary axis vectors (due, for example, to temperature fluctuations, or other influential

factors) can be checked automatically.

For measurement purposes, a calibration sphere is mounted on the table. The sphere is mea-

sured with the probe at three separate swivel positions of the rotary axis and the values obtained

are recorded. CYCLE996 must be called three times for each rotary axis using different swivel

positions. The kinematics calculation is carried out in full once all the rotary axes have been mea-

sured.

Checking the machine with CYCLE996:

X Create a new program to measure the kinematics.

X In the part program editor, select the > > MEASURE MILL > MEASURE WORKPIECE > >>

> KINEMATICS softkeys in the Programs operating area.

X Generate a new swivel data record (where the rotary axis is swiveled) ( ). Ideally, the

swivel positions should create an equilateral triangle, i.e. each one should involve a swivel of

120°.

X Select the rotary axis you want to measure ( ).

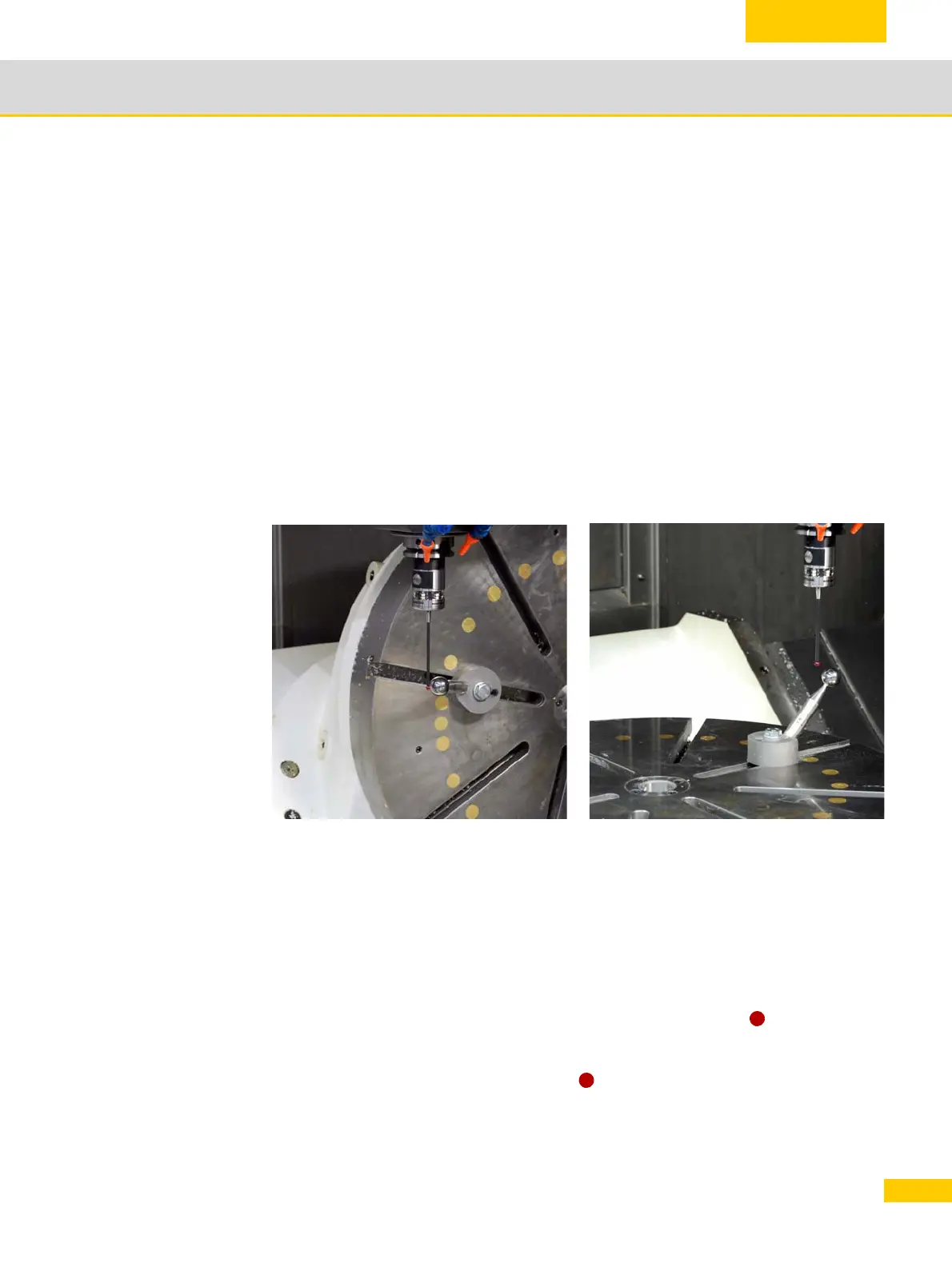

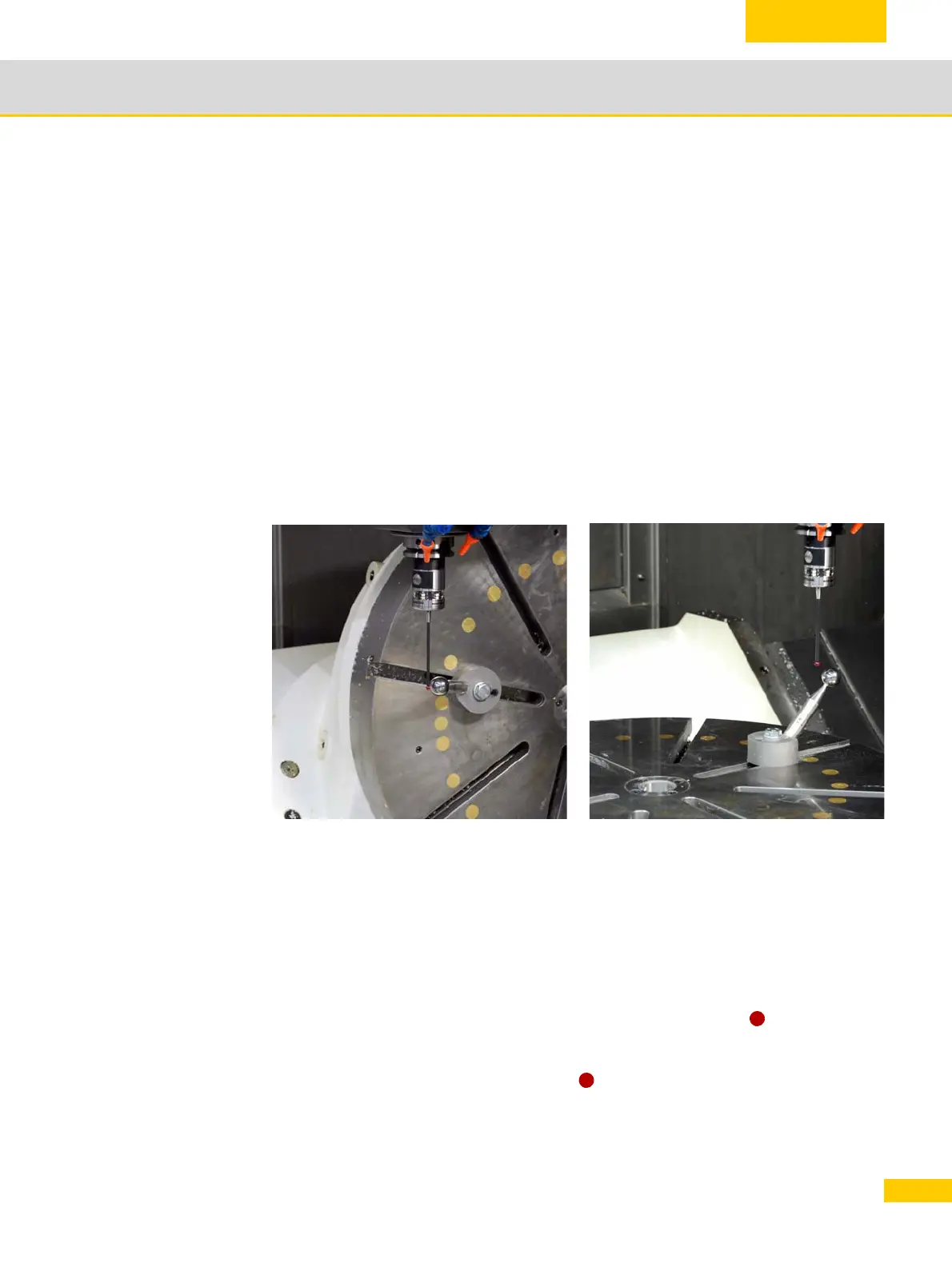

A axis, table kinematics C axis, table kinematics

Three sphere positions (offset from one

another by approx. 120°) are measured for the

A axis.

Three sphere positions (offset from one

another by approx. 120°) are measured for the

C axis.

1

2

Loading...

Loading...